Carrier 48TF 004-007 Gas Heating-Cooling Unit

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair, or service conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters, and replacing filters. All other operations should be performed by trained service personnel. When working on conditioning equipment, observe precautions in the literature, tags and labels attached to the unit, and other safety precautions that apply.

Follow all safety codes. Wear safety glasses and work gloves. Use a quenching cloth for unbrazing operations. Have fire extinguishers available for all brazing operations.

WARNING: Disconnect gas piping from the unit when leak testing at a pressure greater than 1/2 psig. Pressures greater than 1/2 psig will cause gas valve damage, resulting in a hazardous condition. If the gas valve is subjected to pressure greater than 1/2 psig, it must be replaced before use. When pressure testing field-supplied gas piping at pressures of 1/2 psig or less, a unit connected to such piping must be isolated by manually closing the gas valve.

Before performing service or maintenance operations on the unit, turn off the main power switch to the unit and install a lockout tag. Electrical shock could cause personal injury.

INSTALLATION

The unit is shipped in the vertical duct configuration. To convert to horizontal configuration, remove and save the screws from the side duct opening covers, and remove the covers. Using the same screws, install covers on vertical duct openings with the insulation side down. Seals around duct openings must be tight.

Confirm before installation of the unit that the voltage, amperage, and circuit protection requirements listed on the unit data plate agree with the power supply provided.

Step 1: Provide Unit Support

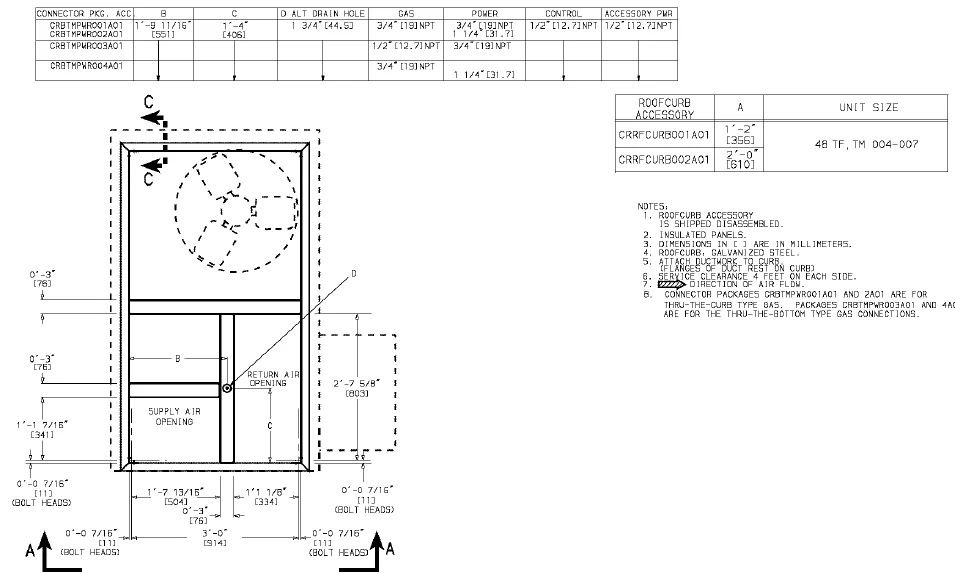

ROOF CURB

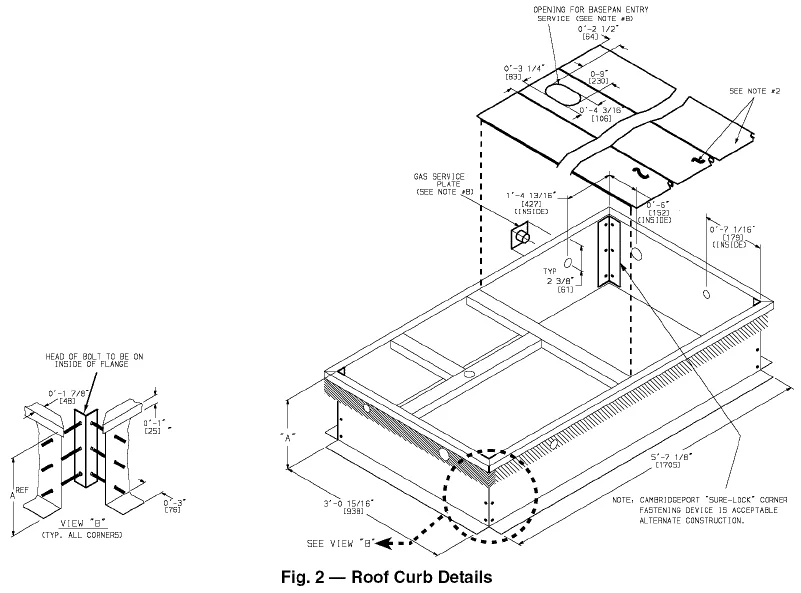

Assemble and install the accessory roof curb in accordance with the instructions shipped with the curb.

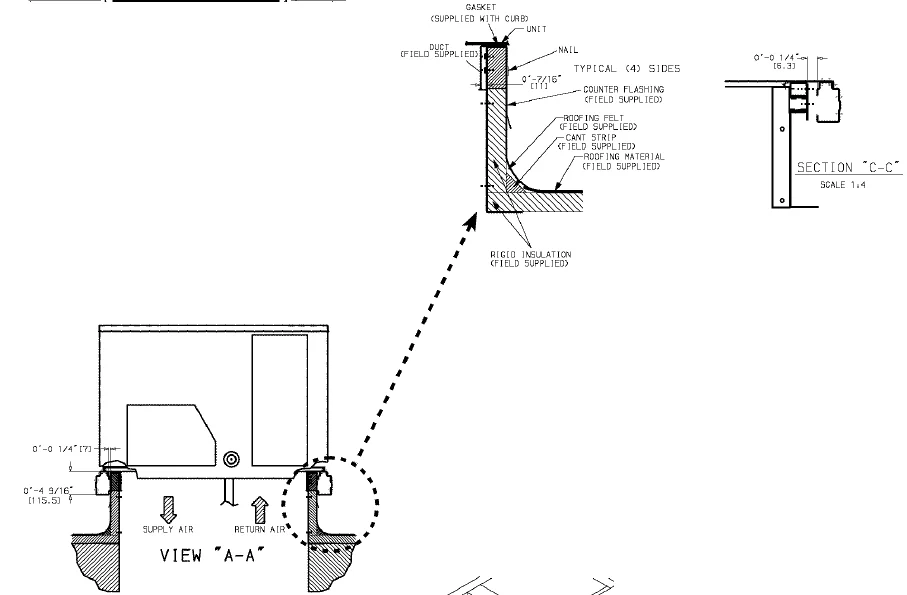

Install insulation, cant strips, roofing felt, and counter flashing as shown. Ductwork must be attached to the curb, not to the unit.

The accessory through-the-bolton power and gas connection package must be installed before the unit is set on the roof curb. If field-installed (thin-the-roof curb) gas connections the desired, use factory-supplied 3/4-in. Pipe coupling and gas plate assembly to mount the thin-the-roof curb connection to the roof crag.

Gas connections and power connections to the unit must be field-installed after the unit is installed on the roof curb.

If electric and control wiring is to be routed through the basepan, attach the accessory through-the-bottom service connections to the basepan in accordance with the accessory installation instructions.

IMPORTANT: Tile gasketing of the tile unit to the tile roof curb is critical for a watertight seal. Install the gasket supplied with the roof curb as shown. An improperly applied gasket can result in air leaks and poor pool unit performance.

The curb should be level. Unit leveling tolerances are shown in Fig. 3. This is necessary for unit drain to function properly. Refer to Accessory Roof Curb Installation Instructions for additional information as required.

SLAB MOUNT (Horizontal Units Only)

Provide a level concrete slab that extends a minimum of 6 in. beyond the unit cabinet. Install a gravel apron in front of the condenser coil air inlet to prevent gross and foliage from obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if required.

ALTERNATE UNIT SUPPORT (Curb or Slab Mount)

A non-combustible sleeper rail can be used in the unit curb support tuea. If sleeper rails cannot be used, support the long sides of the unit with a minimum of 3 equally spaced 4-in. x 4-in. pads on each side.

Step 2: Field Fabricate Ductwork

Secure all ducts to the roof curb and building structure on vertical ducted units. Do not connect ductwork to the unit. For horizontal applications, field-supplied flanges should be attached to horizontal duct openings, and all ductwork should be secured to the flanges. Insulate and weatherproof all external ductwork, joints, and roof openings with counter flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet return air static pressure (a negative condition) shall not exceed 0.35 in. wg with economizer or 0.45 in. wg without economizer.

These units are designed for a minimum continuous heating return-air temperature of 50°F (dry bulb), or an intermittent operation down to 45°F (dry bulb), such as when used with a night set-back thermostat. To operate at lower return-air temperatures, a field-supplied outdoor air temperature control must be used to initiate both stages of heat when the temperature is below 45°F. Indoor comfort may be compromised when these lower air temperatures are used with insufficient heating temperature rise.

Step 3: Install an External Trap for Condensate Drain

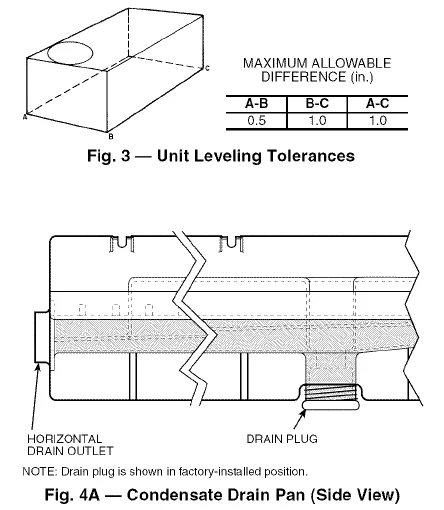

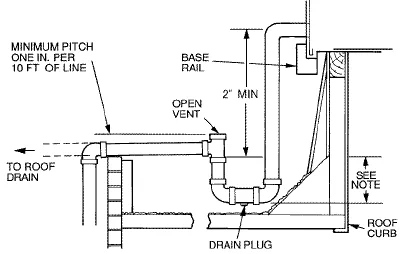

The unit’s 3/4-in. Condensate drain connections are located on the bottom and side of the unit. Unit discharge connections do not determine the use of drain connections; either drain connection can be used with vertical or horizontal applications.

When using the standard side drain connection, make sure the plug (Red) in the alternate bottom connection is tight before installing the unit.

To use the bottom drain connection for a roof curb installation, relocate the factory-installed plug (Red) from the bottom connection to the side connection. The center drain plug looks like a star connection; however, it can be removed with a l/2-in. Socket drive extension. See Fig. 4A. The piping for the condensate drain and external trap can be completed after the unit is in place. See Fig. 4B.

All units must have an external trap for condensate drainage. Install a trap at least 4 in. deep and protect against freeze-up. If the drain line is installed downstream from the external trap, pitch the fine away from the unit at 1 in. per 10 ft of run. Do not use a pipe size smaller than the unit connection (3/4 in.).

Step 4: Rig and Place Unit

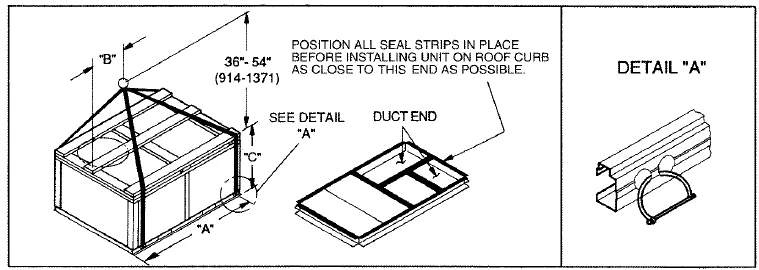

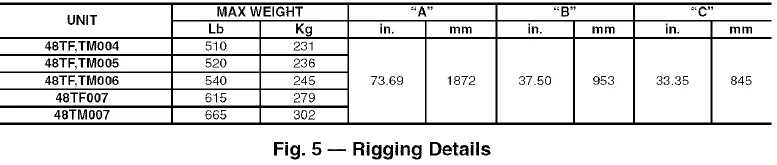

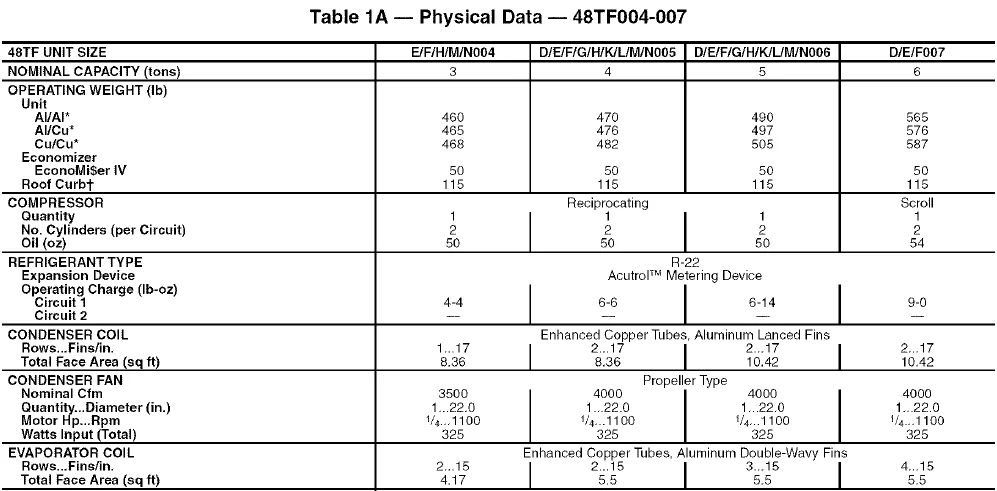

Inspect the unit for transportation damage. File any claim with the transportation agency. Keep the unit upright and do not drop. Spreader bars are not required if the top crating is left on the unit. Rollers may be used to move the unit across a roof. Level by using the unit flame as a reference. See Tables 1A and 1B and Fig. 5 for additional information.

Lifting holes are provided in base rails as shown in Fig. 6A and 6B. Refer to the rigging instructions on the unit.

Caution: All panels must be in place when rigging. The unit is not designed for handling by a fork truck. Damage to the unit may result.

POSITIONING

Maintain clearance around and above the unit to provide a minimum distance from combustible materials, proper airflow, and service access. See Fig. 6A and 6B. A properly positioned unit will have the following clearances between the unit and the roof curb: 1/4-in. Clearance between the roof curb and base rails on each side and the duct end of the unit; 1/4-in. Clearance between the roof curb and the condenser coil end of the unit. (See Fig. 2, section C-C.)

NOTES:

- Dimensions in ( ) are in millimeters.

- Hook rigging shackles through holes in the base rail, as shown in detail “A.” Holes in the base rails are centered around the unit center of gravity. Use a wooden top skid when rigging to prevent the rigging straps from damaging the unit.

- Unit weights do not include the economizer. See Tables 1A and 1B for economizer weights.

CAUTION: All panels must be in place when rigging. The unit is not designed for handling by fork truck. Damage to the unit may result.

NOTES

- DIMENSIONS IN [ ] ARE IN MILLIMETERS.

CENTER OF GRAVITY.

CENTER OF GRAVITY. DIRECTION OF AIR FLOW.

DIRECTION OF AIR FLOW.- ON VERTICAL DISCHARGE UNITS, DUCTWORK TO BE ATTACHED TO ACCESSORY ROOF CURB ONLY. FOR HORIZONTAL DISCHARGE UNITS, FIELD-SUPPLIED FLANGES SHOULD BE ATTACHED TO THE HORIZONTAL DISCHARGE OPENING.

Step 5: Install Flue Hood

Flue hood is shipped screwed to the basepan beside the burner compartment access panel. Remove from shipping location and using the screws provided, install the flue hood and screen in the location shown in Fig. 7.

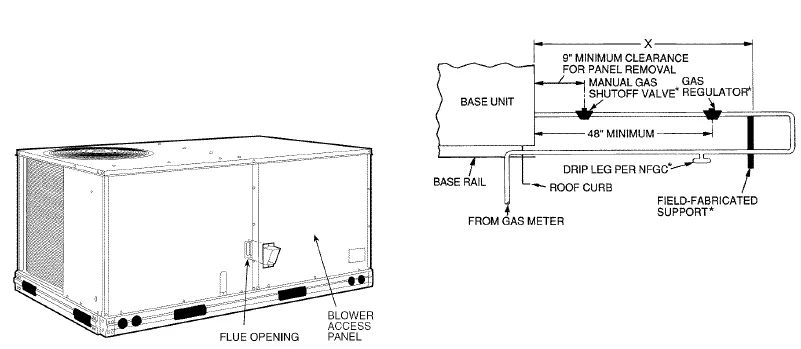

Step 6: Install Gas Piping

The unit is equipped for use with the type of gas shown on the nameplate. Refer to local building codes, or in the absence of local codes, to ANSI Z223.1 entitled National Fuel Gas Code. In Canada, installation must be in accordance with the CANI.BI49A and CANI.BI49.2 installation codes for gas-burning appliances.

For natural gas applications, gas pressure at the unit gas connection must not be less than 4 in. wg or greater than 13.0 in. wg while the unit is operating. On 48TF005, 006, 007 high heat units, the gas pressure at the unit gas connection must not be less than 5 in. wg or greater than 13 in. wg while the unit is operating. For propane applications, the gas pressure must not be less than 5 in. wg or greater than 13 in. wg at the unit connection.

Size gas supply piping for 0.5 in. wg maximum pressure drop. Do not use a supply pipe smaller than the unit gas connection. Support gas piping as shown in the table in Fig. 8. For example, a 3-h-in. gas pipe must have one field-fabricated support beam every 8 ft. Therefore, an 18-1l long gas pipe would have a minimum of 2 support beams, a 48-ft long pipe would have a minimum of 6 support beams.

See Fig. 8 for the typical pipe guide and the locations of the external manual main shutoff valve.

CAUTION: When connecting the gas line to the unit gas valve, the installer MUST use a backup wrench to prevent damage to the valve.

PRE START-UP

Warning

Failure to observe the following warnings could result in serious personal injury.

- Follow recognized safety practices and wear protective goggles when checking or servicing the refrigerant system.

- Do not operate the compressor or provide any electric power to the unit unless the compressor terminal cover is in place and secured.

- Do not remove the compressor terminal cover until all electrical sources are disconnected.

- Relieve all pressure from the system before touching or disturbing anything inside the compressor terminal box if a refrigerant leak is suspected around the compressor terminals.

- Never attempt to repair a soldered connection while the refrigerant system is under pressure.

- Do not use a torch to remove any component. The system contains oil and refrigerant under pressure. To remove a component, wear protective goggles and proceed as follows:

- Shut off the gas and then the electrical power to the unit. Install a lockout tag.

- Relieve all pressure from the system using both high-pressure and low-pressure ports. Recover refrigerant.

- Cut the component connection tubing with a tubing cutter and remove the component from the unit.

- Carefully unsweat the remaining tubing stubs when necessary. Oil can ignite when exposed to torch flame.

Proceed as follows to inspect and prepare the unit for initial start-up:

- Remove all access panels.

- Read and follow instructions on all WARNING, CAUTION, and INFORMATION labels attached to, or shipped with, the unit.

- Make the following inspections:

- Inspect for shipping and handling damages such as broken lines, loose parts, or disconnected wires, etc.

- Inspect for oil at all refrigerant tubing connections and on the unit base. Detecting oil generally indicates a refrigerant leak. Leak-test all refrigerant tubing connections using an electronic leak detector, halide torch, or liquid-soap solution.

- Inspect all field and factory-wiring connections. Be sure that connections are completed and tight.

- Inspect coil fins. If damaged during shipping and handling, cm’elhlly straighten the fins with a fin comb.

- Verify the following conditions:

- Make sure that the condenser fan blade is correctly positioned in the fan orifice. See Condenser-Fan Adjustment section on page 58 for more details.

- Make sure that the air filter(s) are in place.

- Make sure that the condensate drain trap is filled with water to ensure proper drainage.

- Make sure that all tools and miscellaneous loose parts have been removed.

START-UP

Unit Preparation

Make sure that the unit has been installed in accordance with these installation instructions and applicable codes.

Return-Air Filters

Make sure the correct filters are installed in filter tracks. See Tables 1A and 1 B. Do not operate the unit without return-air filters.

Compressor Mounting

Compressors are internally spring-mounted. Do not loosen or remove compressor holddown bolts.

Internal Wiring

Check all electrical connections in the unit control boxes. Tighten as required.

Gas Piping

Check gas piping for leaks.

WARNING

Disconnect gas piping from the unit when leak testing at a pressure greater than 1/2 psig. Pressures greater than 1/2 psig will cause gas valve damage, resulting in a hazardous condition. If the gas valve is subjected to pressure greater than 1/2 psig, it must be replaced before use. When pleasure testing field-supplied gas piping at pressures of 1/2 psig or less, a unit connected to such piping must be isolated by manually closing the gas valve.

Refrigerant Service Ports

To service refrigerant service ports, remove the compressor access panel. Each unit system has 3 Schmder-type service gage ports: one on the suction line, one on the liquid line, and one on the compressor discharge line. Be sure that the caps on the ports me tightly. The Schmder-type valve on the discharge line is located under the low-pressure switch. Another valve is located on the discharge line underneath the high-pressure switch. It is screwed on a Schmder fitting, but there is no Schmder core.

High Flow Valves

Located on the compressor hot gas and suction tubes me High Flow Valves. Large black plastic caps distinguish these valves with O-rings located inside the caps. These valves cannot be accessed for service in the field. Ensure the plastic caps me in place and tight, or the possibility of refrigerant leakage could occur.

Compressor Rotation

On 3-phase units with scroll compressors, it is important to be certain the compressor is rotating in the proper direction. To determine whether or not the compressor is rotating in the proper direction:

- Connect service gauges to suction and discharge pressure fittings.

- Energize the compressor.

- The suction pressure should drop, and the discharge pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

- Note that the evaporator fan is probably also rotating in the wrong direction.

- Turn off the power to the unit.

- Reverse any two of the unit power leads.

- Reapply power to the compressor.

The suction and discharge pressure levels should now move to their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direction, the unit makes an elevated level of noise and does not provide cooling.

Cooling

Set the space thermostat to the OFF position. To start the unit, turn on the main power supply. Set the system selector switch to the COOL position and the fan switch to the AUTO position. Adjust the thermostat to a setting below room temperature. The compressor starts on the closure of the contactor.

Check unit charge. Refer to the Refrigerant Charge section, page 49.

Reset thennostat at a position above room temperature. The compressor will shut off. The evaporator fan will shut off after a 30-second delay.

TO SHUT OFF THE UNIT

Set the system selector switch to the OFF position. Resetting the thermostat at a position above room temperature shuts the unit off temporarily until the space temperature exceeds the thermostat setting.

For more Manuals by Carrier, visit ManualsLibraryy

Carrier 48TF 004-007 Gas Heating-Cooling Unit-FAQs

What is the Carrier 48TF series?

The Carrier 48TF series is a commercial rooftop packaged gas heating and cooling unit designed for reliable performance, energy efficiency, and long service life in commercial buildings.

What does the Carrier model number 48TF indicate?

In Carrier nomenclature, “48” identifies a packaged gas/electric rooftop unit, while “TF” refers to a specific design series with factory-installed heating and cooling components.

What do the numbers 004 to 007 mean in Carrier 48TF units?

The numbers 004–007 indicate different unit sizes and cooling capacities within the 48TF series, allowing users to choose the right capacity for their building needs.

How do I determine the tonnage of a Carrier 48TF unit?

Carrier model numbers usually include size codes where each number represents tonnage. For example, “004” typically equals 4 tons, while “007” represents 7 tons of cooling capacity.

What type of refrigerant is used in Carrier 48TF units?

Most Carrier 48TF units use R-410A refrigerant, which provides efficient cooling and meets modern environmental standards.

How much refrigerant does a Carrier rooftop unit need?

Refrigerant charge generally ranges between 2–4 pounds per ton of cooling, but the exact amount depends on the unit size and system configuration.

Can I fix an EC error myself?

Basic resets can be attempted, but professional HVAC service is recommended, as electrical repairs can be unsafe without proper training.

What does an EC error code mean on a Carrier unit?

An EC error often indicates a problem with electrical components, sensors, or communication between system controls and should be inspected by a qualified technician.