Kenmore 7957206311 Bottom-Mount Series Refrigerator

SAFETY PRECAUTIONS

Please read the following instructions before servicing your refrigerator.

- Unplug the power before handling any electrical components.

- Check the rated current, voltage, and capacity.

- Take caution not to get water near any electrical components.

- Use exact replacement parts.

- Remove any objects from the top before tilting the product.

SPECIFICATIONS

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT – RECONNECT ALL GROUNDING DEVICES

All parts of this appliance capable of conducting electrical current are grounded. If grounding wires, screws, straps, clips, nuts or washers used to complete a path to ground are removed for service, they must be returned to their original position and properly fastened.

IMPORTANT NOTICE

This information is intended for use by individuals possessing adequate backgrounds of electrical, electronic and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

ELECTRICAL SPECIFICATIONS

- Temperature Control (Freezer Compartment). -6°F to +8°F

- Defrost Control ……Total Comp Running Time: 7 hrs~50 hrs

- Defrost Thermostat ……………………………………………… 41°F

- Electrical Rating: 115VAC, 60Hz ………………………….. 5.2 A

- Maximum Current Leakage ……………………………….. 0.5 mA

- Maximum Ground Path Resistance ………………. 0.14 Ohms

- Energy Consumption …………. 31 cu ft. 578 kWh/yr (E/STAR)

NO LOAD PERFORMANCE

CONTROL POSITION: MID/MID

- And Ambient of : ……………. 70°F …………………………… 90°F

- Fresh Food, °F ……………… 33°F to 41°F …….. 33°F to 41°F

- Frozen Food, °F ……………. -4°F to +4°F ……… -4°F to +4°F

- Percent Running Time …… 50%-65% …………….. 65%-80%

REFRIGERATION SYSTEM

- Minimum Compressor Capacity Vacuum ……………. 21 MIN.

- Minimum Equalized Pressure

- @ 70°F …………………………………………………… 49 PSIG

- @ 90°F …………………………………………………… 56 PSIG

- Refrigerant R134a …………………………………………… 4.76 oz.

- Compressor …………………………………………….. 1023 BTU/hr

INSTALLATION

Clearance must be provided at rear of the refrigerator for air circulation.

- AT REAR ……………………………………………………………… 2 in

REPLACEMENT PARTS

- Overload Protector …………………………………. 6750CL0001D

- R-Defrost Thermostat …………………………….. 6615JB2005R

- F-Defrost Thermostat ……………………………… 6615JB2005S

- F-Defrost Heater …………………………………… MEE62225101

- R-Defrost Heater …………………………………… MEE62105201

- F-Evaporator Fan Motor …………………………. EAU60694510

- R-Evaporator Fan Motor …………………………. EAU36179305

- Capacitor (Running) ………………………………. EAE58905704

- Compressor (Hi-Side) …………………………….. TCA35271201

- R-Evaporator(Lo-Side)…………………………….. ADL73341401

- F-Evaporator(Lo-Side) ……………………………. ADL73341301

- Conderser ……………………………………………. ACG72915206

- Dryer …………………………………………………….5851JA2008W

- Condenser Fan Motor …………………………… EAU61505101

- Temperature Control ……………………….. ACQ85571105(ST)

- Main Control………………………………………….. EBR73093603

- Ice Fan Motor ………………………………………… EAU60694511

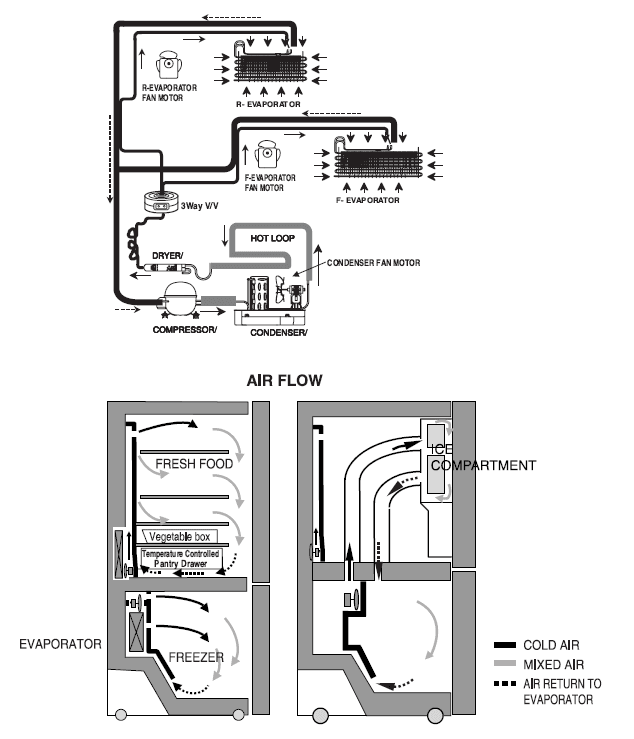

AIR FLOW / CIRCULATION D’AIR

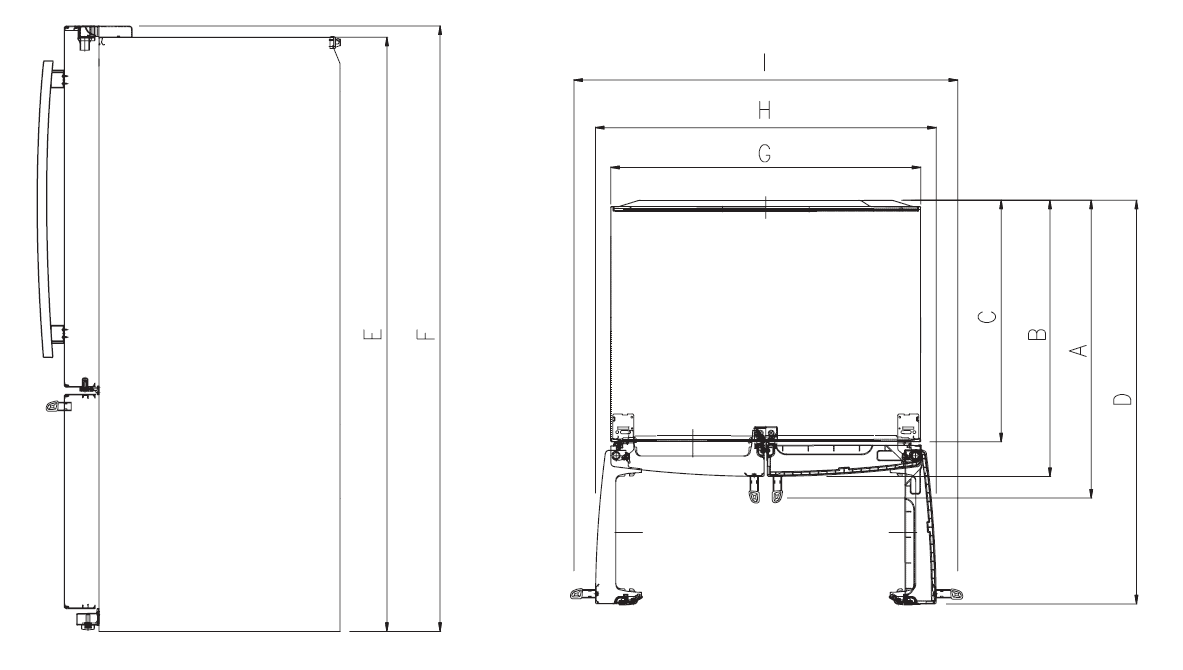

| Description | 795.7206* | |

| Depth w/ Handles | A | 36 1/4 in |

| Depth w/o Handles | B | 33 3/4 in |

| Depth w/o Door | C | 29 1/2 in |

| Depth (Total with Door Open) | D | 48 1/8 in |

| Height to Top of Case | E | 68 3/4 in |

| Height to Top of Door Hinge | F | 70 1/4 in |

| Width | G | 35 3/4 in |

| Width (door open 90 deg. w/o handle) | H | 40 in |

| Width (door open 90 deg. w/ handle) | I | 44 1/4 in |

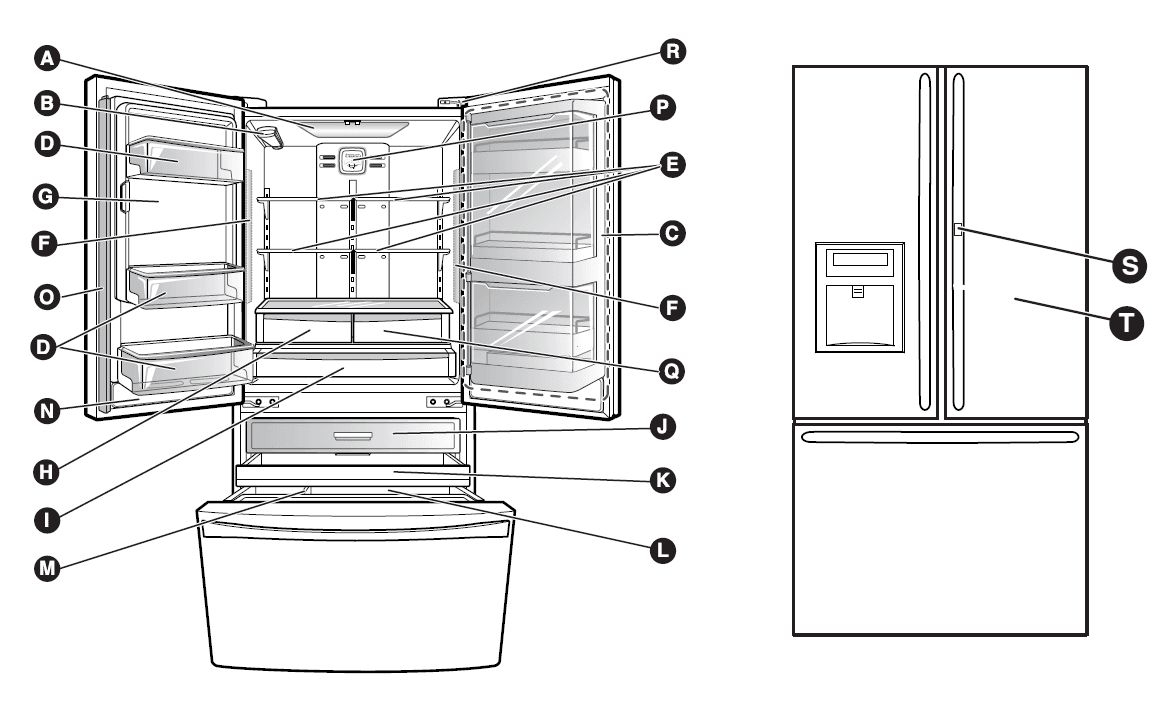

PARTS IDENTIFICATION

Use this page to become more familiar with the parts and features of your refrigerator. Page references are included for your convenience.

NOTE: This guide covers several different models. The refrigerator you have purchased may have some or all of the items listed below. The locations of the features shown below may not match your model.

- A Refrigerator Light (Top)

- B Water Filter (Inside)

- C Case Assembly, Home Bar

- D Fixed Door Bins

- E Refrigerator Shelves

- F Refrigerator Light

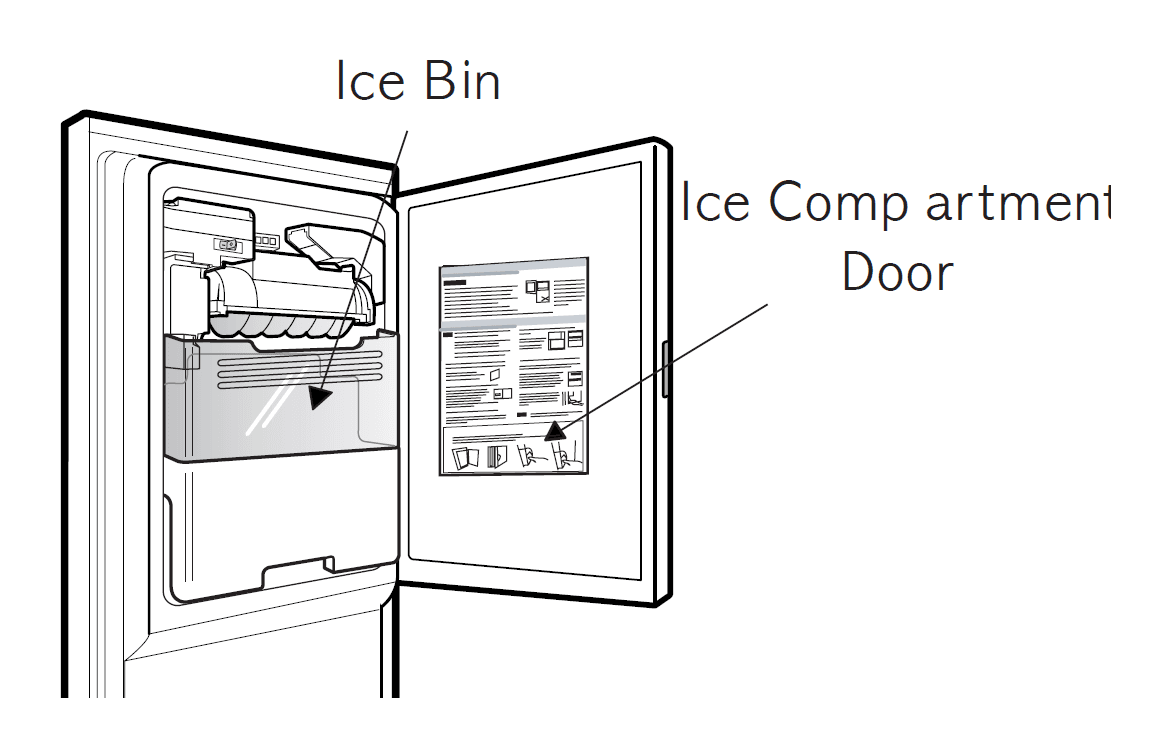

- Ice Compartment (Icemaker and Ice Bin)

- Humidity Controlled Crisper

- Temperature Controlled Pantry Drawer

- Pullout Drawer (Top)

- Pullout Drawer (Middle)

- L Durabase

- M Durabase Divider

- N Water Tank Cover

- O Articulating Mullion

- P Air Filter

- Q Airtight Crisper

- R Kenmore Connect

- S Push, Button

- T Homebar, Door

DISASSEMBLY

REMOVING AND REPLACING REFRIGERATOR DOORS

To remove the left refrigerator door:

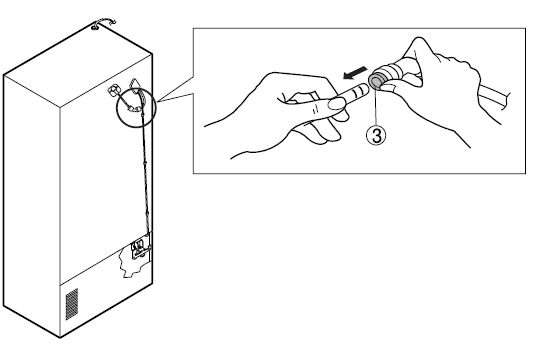

Pull the water tube out of the fitting while pressing the release ring on the fitting. When you pull out the tube, first you have to push the collet in the opposite direction of the arrow in the upper picture, and tube pull out in the direction of the arrow. CAUTION: Before you begin, remove food and bins from the doors.

CAUTION: Before you begin, remove food and bins from the doors.

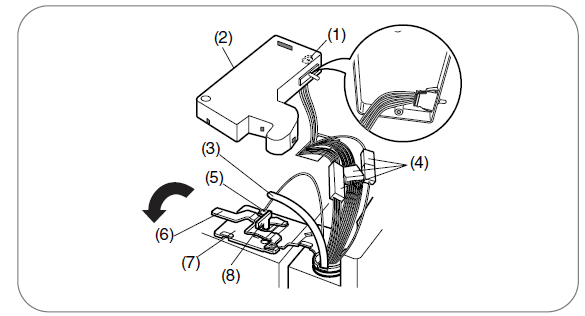

- Open the door. Remove the top hinge cover screw (1).

- Use a flat-head screwdriver to pry back the hooks (not shown) on the front underside of the cover (2). Lift up the cover.

- Remove the cover. Pull out the tube (3).

- Disconnect all the wire harnesses (4).

- Remove the grounding screw(5)

- Rotate hinge lever (6) counterclockwise. Lift the top hinge (7) free of the hinge lever latch (8).

IMPORTANT: When lifting the hinge free of the latch, be careful that the door does not fall forward. - Lift the door from the middle hinge pin and remove the door.

- Place the door, inside facing up, on a nonscratching surface.

To remove the Right refrigerator door:

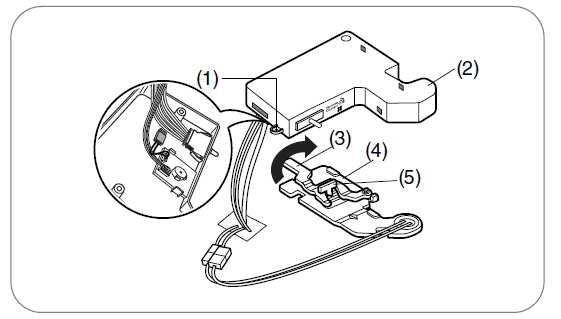

- Open the door. Remove the top hinge cover screw (1). Lift up the cover (2).

- Remove the cover.

- Rotate the hinge lever (3) clockwise. Lift the top hinge (4) free of the hinge lever latch (5).

IMPORTANT: When lifting the hinge free of the latch, be careful that the door does not fall forward.

WARNING

Explosion Hazard

- Disconnect the electrical supply to the refrigerator before installing. Failure to do so could result in death or serious injury.

- Do not put hands or feet or other objects into the air vents, base grille, or bottom of the refrigerator. You may be injured or receive an electrical shock.

- Be careful when you work with the hinge, base grille, and stopper. You may be injured.

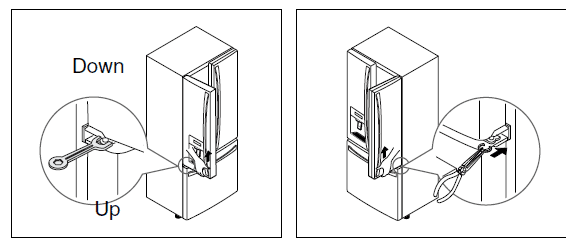

Door Alignment

If the level of refrigerator doors is uneven, follow the instructions below to align the doors: Turn the leveling legs (CCW) to raise or (CW) to lower the height of the front of the refrigerator by using flat blade screw driver or 11/32″ wrench. Use the wrench (Included with the User Manual) to adjust the bolt in the door hinge to adjust the height. (CW to raise or CCW to lower the height.) The Left refrigerator door has an adjustable nut, located on the bottom hinge, to raise and lower it to align properly. If the space between your doors is uneven, follow the instructions below to align the Left door evenly: Use the wrench (included with the Use & Care Guide) to turn the nut in the door hinge to adjust the height. To the right to raise or to the left to lower the height. On the other hand, The Right refrigerator door does not have an adjustable nut. If the space between your doors is uneven, follow the instructions below to align the Right door:

- With one hand, lift up the Right door you want to raise at the middle hinge.

- On the other hand, use pliers to insert the snap ring as shown.

- Insert additional snap rings until the Right door is aligned. (Three snap rings are provided with the unit.)

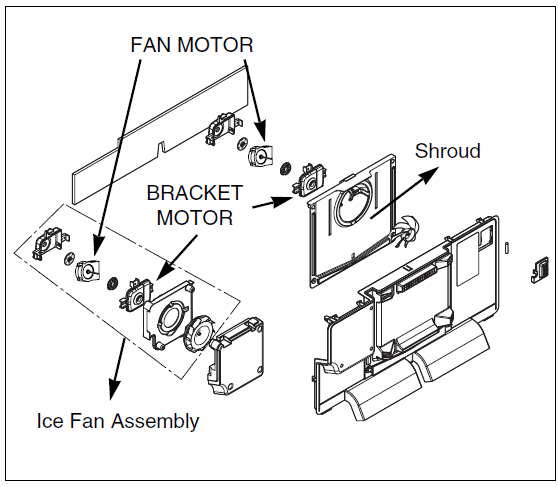

FAN AND FAN MOTOR

FAN AND FAN MOTOR(Freezer Room)

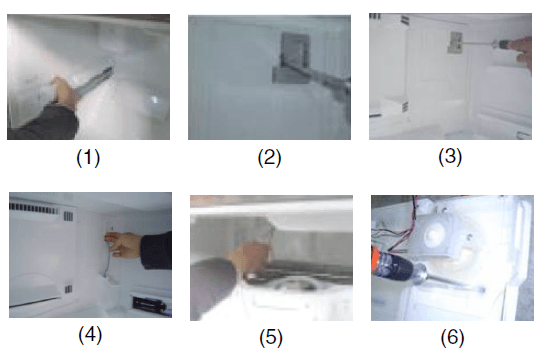

- Remove the freezer drawer.

- Remove the plastic guide for slides on left side by unscrewing phillips head screws.

- Remove the grille assembly by removing four screws and pulling the grille assembly forward.

- Remove the Fan Motor assembly by loosening 3 screws and disassembling the shroud.

- Pull out the fan and separate the Fan Motor and Bracket Motor.

* Ice Fan Assembly Replacement

- Remove the plastic guide for slides on left side by unscrewing phillips head screws.

- Pull out the cover sensor to disassemble by using the tools shown in the figure.

- Pull out the cover grille to disassemble by using the tools shown in the figure.

- Put your hand into the inside of grille to disassemble as shown in the figure.

- Disconnect the wire harness of the grille assembly.

- Remove the Ice fan assembly by loosening all screws.

FAN AND FAN MOTOR(Refrigerator Room)

- Remove all the shelf and guide rail on the left side.

- Remove the upper and lower Caps by using a flat screwdriver. And then, remove 2 screws under Caps.

- Pull out the Multi Duct outward slightly.

- Disconnect the lead wire on the bottom as shown.

- Grip both sides of Multi Duct, pull it out.

- Remove the Shroud Refrigerator by loosening 4 screws and disassembling the Multi Duct.

- Pull out the Fan Motor

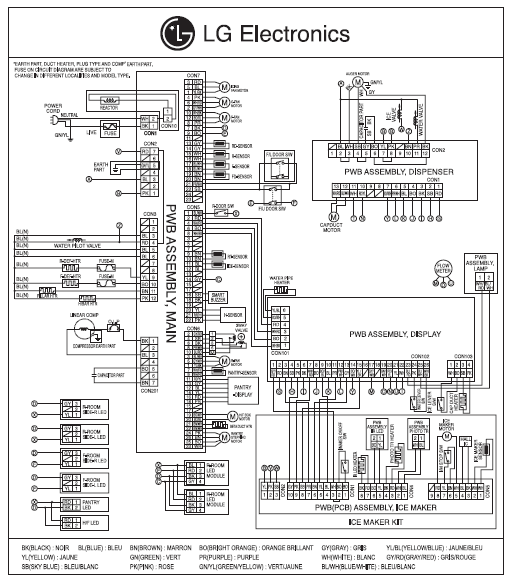

CIRCUIT DIAGRAM

TROUBLESHOOTING

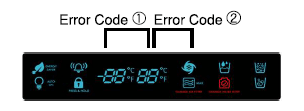

Error Code Summary

WARNING: When you check the Resistance values, be sure to turn off the power. And wait for the voltage discharge to be sufficient.

NOTE)

- When 3 hours passed after the error happened, all main errors were displayed on the display panel except the sub-error.

- Sub error is not displayed before pressing the Ultra ICE button and Freezer button simultaneously.

- Sub errors as follows: “Er rt”, “Er SS”, “Er IS(except Icing sensor error)”, “Er gF”, “Er It”, “Er HS”

- “Er IS,” which is displayed without the input of user, is an icing sensor error.

| NO | Error Detection Category | Error Display | Error Generation Factors | Remark | |

| Freezer Temperature (Error code ①) | Refrigerator Temperature (Error code ②) | ||||

| 1 | Normality | None | Normal operation of Display | ||

| 2 | Freezer Sensor Error | Er | FS | Short or Disconnection of Freezer Sensor |

Check Each sensor and its Connector. |

| 3 | Refrigerator Sensor Error | Er | rS | Short or Disconnection of Refrigerator Sensor | |

| 4 | Freezer Defrost Sensor Error | F | dS | Short or Disconnection Of Defrost Sensor | |

| 5 | Refrigerator Defrost Sensor Error | r | dS | Short or Disconnection Of Defrost Sensor | |

| 6 | Humidity Sensor Error | Er | HS | Short or Disconnection Of Humidity | |

| 7 | Icing Sensor Error | Er | IS | Short or disconnection of the sensor about Ice maker (Icing sensor, Ice maker sensor) | |

| 8 | Pantry sensor error | Er | SS | Short or Disconnection of Pantry Sensor | |

| 9 | Room Temp Sensor Error | Er | rt | Short or Disconnectoin of Room temp.sensor | |

| 10 | Ice maker kit defect | Er | It | Other Electric system error such as moter, gear, Hall IC, operation circuit within I/M kit | When the ice does not drop even when the I/M Test S/W is pressed (same as model applied Twisting Ice Maker before) |

| 11 | Flow Meter(Sensor) Defect | Er | gF | Error of flow meter or water input or low water pressure | Error of flow meter or water input or low water pressure or flow meter connection |

| 12 | Freezer Defrosting Error | F | dH | Even though it is passed 80Minute since then Defrosting, If Defrosting sensor is not Over 40 °F (5 °C), it is caused |

Temperature Fuse Disconnection Heater Disconnection, DRAIN Jam, Poor Relay for Heater |

| 13 | Refrigerator Defrosting Error | r | dH | Even though it is passed 50Minute since then Defrosting, If Defrosting sensor is not Over 40 °F(5 °C), it is caused | |

| 14 | Abnormality of BLDC FAN Motor for Ice Making | Er | IF | It is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating | Poor BLDC Motor connection, DRIVE IC, and TR |

| NO | Error Detection Category | Error Display | Error Generation Factors | Remark | |

| Freezer Temperature (Error code ①) | Refrigerator Temperature (Error code ②) | ||||

| 15 | Abnormality of BLDC FAN Motor for Freezer | Er | FF | It is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating | Poor BLDC Motor connection, DRIVE IC, and TR |

| 16 | Abnormality of BLDC FAN MOTOR For Refrigerator | Er | rF | It is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating | Poor BLDC Motor connection, DRIVE IC, and TR |

| 17 | Abnormality of BLDC FAN Motor for Mechanic Room | Er | CF | It is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating | Poor BLDC Motor connection, DRIVE IC, and TR |

| 18 | Communication Error | Er | CO | Communication Error between Micom of Main PCB and Display Micom | Poor Communication connection,Poor TR of Transmitter and Receiver Tx/Rx between display and main board. |

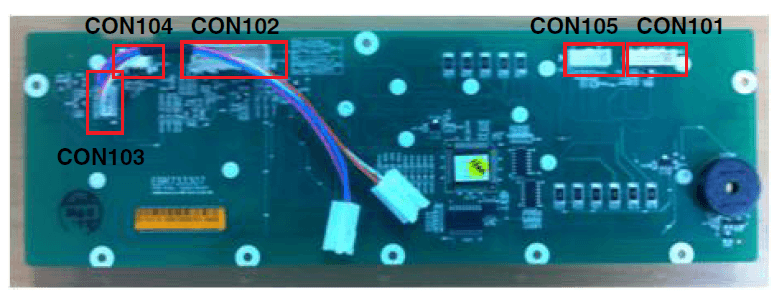

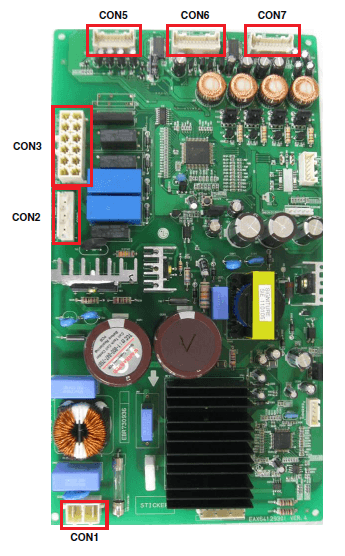

PCB Picture

Main PCB

| P/No & MFG | Picture |

|

EBR730936 (2011.01~) |  |

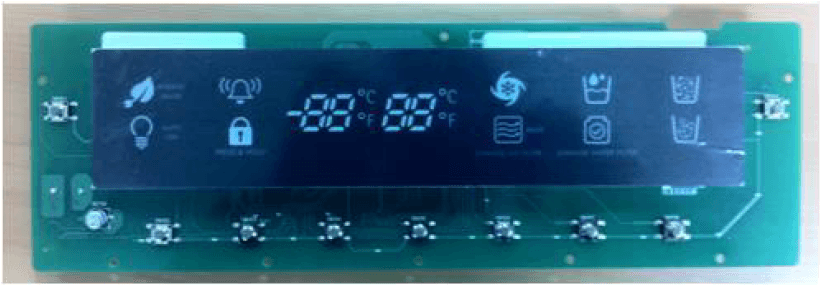

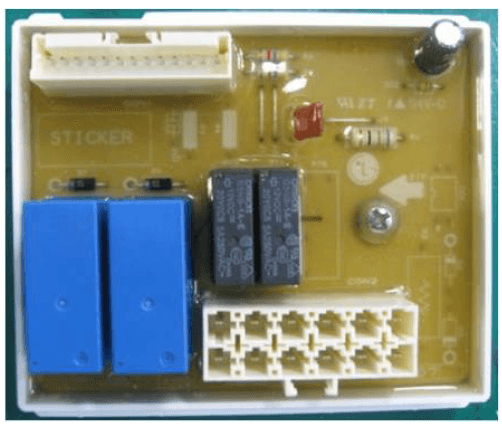

Display PCB & Sub PCB

| P/No | Picture |

|

Display PCB EBR73330702 (2011.03.30) |

|

|

| |

|

Sub PCB EBR60070710 (2011.01~) |  |

TEMPERATURE CHART – FREEZER AND ICING SENSOR

| TEMP | RESISTANCE | VOLTAGE |

| -39°F (-40°C) | 73.29 ㏀ | 4.09 V |

| -30°F (-35°C) | 53.63 ㏀ | 3.84 V |

| -21°F (-30°C) | 39.66 ㏀ | 3.55 V |

| -13°F (-25°C) | 29.62 ㏀ | 3.23 V |

| -4°F (-20°C) | 22.33 ㏀ | 2.89 V |

| 5°F (-15°C) | 16.99 ㏀ | 2.56 V |

| 14°F (-10°C) | 13.05 ㏀ | 2.23 V |

| 23°F (-5°C) | 10.10 ㏀ | 1.92 V |

| 32°F (0°C) | 7.88 ㏀ | 1.63 V |

| 41°F (+5°C) | 6.19 ㏀ | 1.38 V |

| 50°F (+10°C) | 4.91 ㏀ | 1.16 V |

| 59°F (+15°C) | 3.91 ㏀ | 0.97 V |

| 68°F (+20°C) | 3.14 ㏀ | 0.81 V |

| 77°F (+25°C) | 2.54 ㏀ | 0.67 V |

| 86°F (+30°C) | 2.07 ㏀ | 0.56 V |

| 95°F (+35°C) | 1.69 ㏀ | 0.47 V |

| 104°F (+40°C) | 1.39 ㏀ | 0.39 V |

TEMPERATURE CHART – REFRIGERATOR AND DEFROST SENSOR

| TEMP | RESISTANCE | VOLTAGE |

| -39°F (-40°C) | 225.1 ㏀ | 4.48 V |

| -30°F (-35°C) | 169.8 ㏀ | 4.33 V |

| -21°F (-30°C) | 129.3 ㏀ | 4.16 V |

| -13°F (-25°C) | 99.30 ㏀ | 3.95 V |

| -4°F (-20°C) | 76.96 ㏀ | 3.734 V |

| 5°F (-15°C) | 60.13 ㏀ | 3.487 V |

| 14°F (-10°C) | 47.34 ㏀ | 3.22 V |

| 23°F (-5°C) | 37.55 ㏀ | 2.95 V |

| 32°F (0°C) | 30 ㏀ | 2.67 V |

| 41°F (+5°C) | 24.13 ㏀ | 2.40 V |

| 50°F (+10°C) | 19.53 ㏀ | 2.14 V |

| 59°F (+15°C) | 15.91 ㏀ | 1.89 V |

| 68°F (+20°C) | 13.03 ㏀ | 1.64 V |

| 77°F (+25°C) | 10.74 ㏀ | 1.45 V |

| 86°F (+30°C) | 8.89 ㏀ | 1.27 V |

| 95°F (+35°C) | 7.40 ㏀ | 1.10 V |

| 104°F (+40°C) | 6.20 ㏀ | 0.96 V |

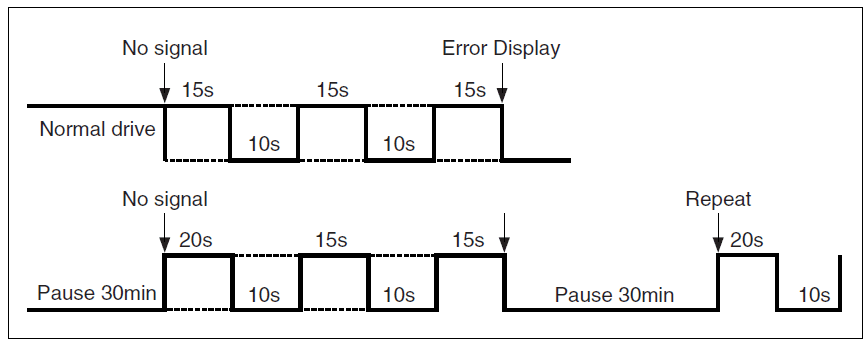

How to check Fan-Error

- After sending a signal to a fan, MICOM checks the BLDC fan motor’s lock status.

If there is no feedback signal from the BLDC fan, the fan motor stops for 10 seconds and then operates for 15 seconds. To determine if there is a fan motor malfunction, this process is repeated 3 times. If the fan motor is determined to be defective, an error code will be shown in the display for 30 minutes. At this point, the process will be repeated until the fan motor operates normally. If normal operation is achieved, the error display disappears and the MICOM is reset automatically.

DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

FUNCTION

Function

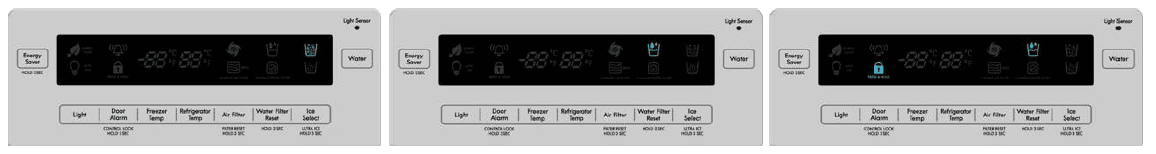

When the appliance is plugged in, the default set values are 37°F for the Refrigerator and 0°F for the freezer. You can adjust the Refrigerator and Freezer control temperature by pressing the ADJUST button on the display

- When the power is initially applied or restored after a power failure, it is set to control the temperature previously.

- If you do not press any button after turning on the power, only the water, Ice type, and lock Icon that has been selected will be turned on, and all other LEDs on the Dispenser Panel will be turned off within 60 seconds. (Power Save Mode)

- If you press a button, only the water, Ice type, and lock Icon that has been selected will be turned on, and all other LEDs on the Dispenser Panel will be turned off within 20 seconds. (Power Save Mode)

How to Toggle the Display between °F & °C

- The initial setting is °F, and the display temperature mode can be converted °F to °C or °C to °F by pressing and holding the Freezer Temperature Button and Refrigerator Temperature Button at the same time for over 5 seconds.

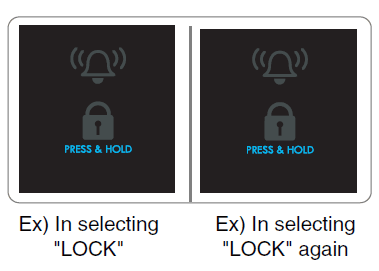

Alarm/Lock function (dispenser and display button lock)

- When the refrigerator is first turned on, the buttons are not locked. “LOCK” is deactivated with the light off.

- To lock the display, the dispenser, and the control panel, press and hold the LOCK button for 3 seconds. “LOCK” is activated with the light on.

- The LOCK button is the only control feature that remains active in the locked state. The buzzer sound, other control buttons, and the dispenser are deactivated.

- To release from the locked state, press and hold the LOCK button again for 3 seconds.

- If you don’t hold the Alarm/Lock button for more than 3 seconds, the Alarm function will be changed, and the alarm for the open door will be on/off same as the alarm icon indicates.

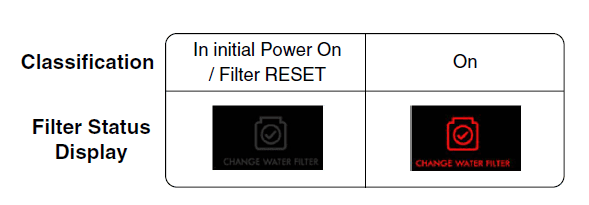

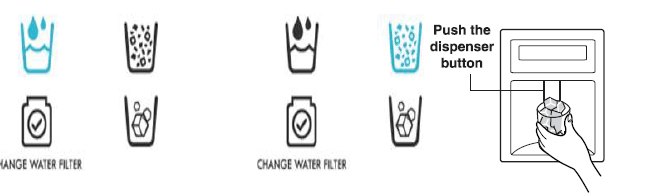

Water Filter condition display function

- There is a replacement indicator light for the water filter cartridge.

- The water filter needs to be replaced every six months for using water filter.

- When the Water Filter Icon lights on, you must exchange the filter.

- After replacing the filter, press and hold the water filter reset button for 3 seconds.

After the water Filter icon turns off with a reset status

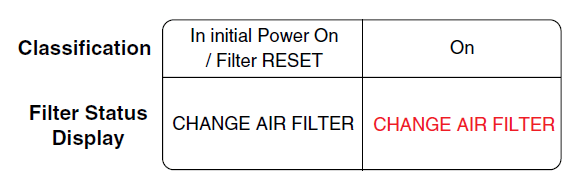

Air Filter condition display function

- There is a replacement indicator light for the air fresh filter cartridge.

- Fresh Air filter needs replacement once every 6 months.

- When the Air Filter Icon lights on, you must replace the filter.

- After replacing the filter, press and hold the Air filter button for more than 3 seconds.

After the Air Filter icon turns off with reset status.

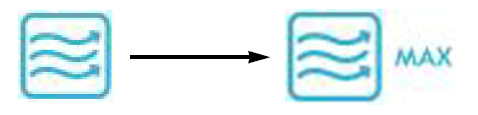

Air Filter Selection

Please select this function for the Air Filter.

- When you press the Air Filter Button, the Air Filter “MAX” Will be turned on again.

- Air Filter MAX function automatically turns off after a fixed time has passed.

Ultra Ice selection

Please select this function for quick freezing.

- When you press the Ultra Ice Button, the Ultra ICE ICON will be turned on again. The

- Ultra Ice function automatically turns off after a fixed time has passed.

Dispenser use selection

You can select water or ice.

- When you press the Water Button, the Water Icon will be selected.

- When you press the Ice button, the Cube/Crush ICON will be selected in order.

- Hold your cup in the dispenser for a few seconds after dispensing ice or water to allow the last pieces of ice or drops of water to fall into the cup.

- When, after initially establishing, the water comes out, the water tank inside fills until the time of the quality hour is reached.

CONTROL OF FREEZER FAN MOTOR

- Freezer fan motor has high and standard speeds.

- When the refrigerator is overloaded, the fan motor runs at high speed as powered-up Standard speeds are used for general purposes.

- To improve cooling speed, the RPM ofthe freezer fan motor changes from normal speed to high.

Cooling Fan Motor

- The cooling fan is switched ON and OFF in conjunction with the compressor.

- The cooling fan Motor has high and standard speeds. (When the room temperature is higher than 38°C speed is high)

- The failure sensing method is the same as in the fan motor of the freezing fan motor(refer to the failure diagnosis function table for failure display).

Ice Compartment Fan

- The Icing Fan is controlled by the sensor on the top of the ice compartment.

- The Failure sensing method is the same as in the fan motor of the freezer (refer to the failure diagnosis function table for failure display)

Refrigeration Room Fan Motor

- The refrigeration room fan is switched ON and OFF in conjunction with the refrigeration room temperature.

- The Failure sensing method is the same as in the fan motor of the freezing fan motor (refer to the failure diagnosis function table for failure display).

Ultra ICE

- The purpose of this function is to intensify the cooling speed of increase the amount of ice.

- Whenever the selection switch is pressed, selection/release, the Icon will turn ON or OFF.

- If there is a power outage and the refrigerator is powered on again, Ultra ICE will be canceled.

- To activate this function, press the Ultra ICE key, and the Icon will turn ON. This function will remain activated for 24 hrs.

For more manuals by Kenmore, visit ManualsLibraryy

Kenmore 7957206311 Bottom-Mount Series Refrigerator-FAQs

Who manufactures Kenmore refrigerators?

Kenmore appliances are made by several manufacturers, including Whirlpool, LG, Electrolux, Panasonic, and Daewoo Electronics.

Is Kenmore a reliable refrigerator brand?

Yes, Kenmore is known for its quality, durability, and customer service. The brand offers long warranties and dependable performance.

Why is my Kenmore fridge not cooling?

Common reasons include a locked compressor, faulty control board, or damaged evaporator. A technician can help diagnose the exact issue.

How do I find out the size (cubic feet) of my Kenmore refrigerator?

Measure the interior width, height, and depth, then multiply those numbers together to calculate the cubic feet. Removing shelves and drawers can help with more accurate measurements.

How long do Kenmore refrigerators typically last?

Kenmore refrigerators generally last between 10 and 20 years, especially with proper care and maintenance.

Are Kenmore and Whirlpool the same?

Not exactly, but Whirlpool manufactures many Kenmore appliances, so parts and design elements often overlap.

How can I determine the age of my Kenmore refrigerator?

First, locate the model and serial number. Then, identify the manufacturer and use their serial number system to find the production date.

What is the ideal freezer temperature for a Kenmore refrigerator?

Set the freezer to 0° Fahrenheit (or -18° Celsius) for optimal food preservation.