Lennox MERIT ML180UH Horizontal Gas Furnace

FEATURES

HEATING SYSTEM

Lennox Duralok™ Heat Exchanger Assembly (1)

- Heavy-gauge aluminized steel heat exchanger.

- Crimped seam, clamshell-type design.

- Designed for normal expansion and contraction.

- Minimum resistance to air flow.

- The heat exchanger has been laboratory life cycle tested in excess of industry standards.

- The compact size of the heat exchanger permits a low overall design of the furnace cabinet.

Inshot Burners (2)

- Aluminized steel in-shot burners provide efficient, trouble-free operation.

- Burner venturi mixes air and gas in the correct proportion for proper combustion.

- The burner assembly is removable from the unit as a single component for ease of service.

SureLight® Hot Surface Ignitor (3)

- Tough, reliable, long-life, trouble-free performance.

- Silicon nitride ignitor.

- Cemented to a steatite block for protection against current leakage.

- Ignition leads are constructed of nickel-plated copper and are enclosed in high-temperature Teflon® insulation for dependable operation.

Gas Control Valve (4)

The 24-volt redundant combination gas control valve combines a manual shut-off switch (On-Off), an automatic electric valve (dual), and gas pressure regulation into a compact combination control.

Combustion Air Inducer (5)

- Shaded-pole heavy-duty blower pre-purges the heat exchanger and safely vents flue products.

- The pressure switch proves blower operation before allowing the gas valve to open.

- Operates only during heating cycle.

- Direct access allows inducer assembly to be rotated 90° clockwise or counterclockwise to facilitate easy vent attachment from either side of the cabinet in upflow applications and from the top in horizontal applications.

Flame Rollout Switches (2) (6)

- Manual reset switches are factory-installed on the burner box.

- Switches provide protection from abnormal operating conditions.

Limit Controls

- Automatic reset, primary, and secondary limits are accurately located.

- Primary limit factory-installed on vestibule panel on all units, secondary limit factory-installed on blower housing.

OPTIONS

High Altitude Pressure Switch Kit

Required on most units for proper unit operation at altitudes from 4,501 to 7500 ft.

Natural Gas to LPG/Propane Conversion Kit

Required for field changeover from natural gas to LPG/Propane.

LPG/Propane to Natural Gas Conversion Kit

Required for field changeover from LPG/Propane to natural gas.

Vent Adaptor (Upflow Applications Only)

- Allows venting through a masonry chimney without the need for a flue liner.

- The manual reset temperature sensor protects against abnormal operating conditions.

- Sensor wiring may be routed from either side of the adaptor.

Minimum winter design temperatures:

- −10°F when used with interior masonry chimneys.

- +5°F when used with exterior masonry chimneys.

Refer to the Winter Design Temperatures Map on page 6 for application information. Also, refer to the installation instructions for detailed information.

BLOWER

Direct drive blower (7)

- Statistically and dynamically balanced.

- Resiliently mounted.

- The blower assembly is easily removed for servicing.

High Efficiency Constant Torque Blower Motor

- ECM (Electronically Commutated Motor) motor.

- The motor is programmed to provide constant torque at each of the selectable speeds.

- Motor is controlled by the Integrated Furnace Control.

- Blower speeds are easily changed on the integrated furnace control. See blower performance tables.

CONTROLS (8)

SureLight® Integrated Furnace Control

- Control contains all necessary controls and relays to operate the furnace.

- The combustion air inducer is operated by the integrated furnace control. Prior to ignition, a pre-purge cycle for 15 seconds is initiated. After the main burners are turned off, a post-purge cycle for 5 seconds is run.

- The flame sensor assures safe and reliable operation.

- Should loss of flame occur, the integrated furnace control will initiate 4 re-attempts at ignition before locking out unit operation for 60 minutes.

- Watchguard-type circuit automatically resets ignition controls after one hour of continuous thermostat demand after unit lockout, eliminating nuisance calls for service.

- Fan control consists of an adjustable blower timed-off delay (60, 90, 120, 180 seconds – factory setting 90 seconds) and a fixed blower timed-on delay (30 seconds – heating, 2 seconds – cooling).

- For air-conditioning applications, the blower is automatically energized on thermostat demand for cooling. Control has a low-speed continuous blower speed setting for humidifier or air cleaner operation.

- Two accessory terminals are furnished for additional power supply requirements for 120-volt (less than 1 amp) power humidifiers and powered air cleaners. One additional terminal is furnished for power supply requirements for 24V (less than 0.5 amp) low-voltage accessories.

- Ignition control has a single red LED to indicate status and as an aid in troubleshooting.

- The last five codes are stored in non-volatile memory (accessible by the recall button on the control) for servicing.

24 Volt Transformer

Furnished and factory-installed on the outside of the control box. A 40VA transformer has a fuse wired in series.

Field Wiring Make-up Box

- Furnished for line voltage wiring.

- Factory-installed internally on the left side of the furnace.

- The box may be installed on the right side of the furnace.

OPTIONS

Thermostat

Thermostat (programmable/non-programmable) is not furnished with the unit. See Thermostat bulletins in Controls Section and Lennox Price Book for selection.

FILTER (NOT FURNISHED)

Filter and provisions for external mounting must be field-provided.

OPTIONS

Air Filter and Rack Kit for Horizontal Return Air (End) Applications

- Washable or vacuum cleanable polyurethane frame type filter and external end return air rack available for field installation.

- The rack has a filter door for easy filter servicing.

- Flanges on the rack allow easy duct connection.

- See the dimension drawing.

Air Filter and Rack Kit for Upflow Side Return Air

- Applications – Not for use with Return Air Base

- Washable or vacuum cleanable polyurethane frame type filter and external side return air rack available for field installation.

- Available in single and ten-pack kits.

- The rack has a filter door for easy filter servicing.

- Flanges on the rack allow easy duct connection.

- Field installs on either side of the unit cabinet. See the dimension drawing.

CABINET

- Low-profile, narrow-width cabinet allows easy installation.

- Heavy-gauge, cold-rolled steel construction.

- Pre-painted cabinet finish.

- The flue outlet on top of the cabinet for upflow applications can be relocated to either side of the cabinet for horizontal applications.

- Flanges are provided on the supply air opening for ease of plenum connection or alignment with the indoor coil.

- Insulated cabinet with foil-faced insulation on sides and back of heating compartment. (9)

- Complete service access.

- The safety interlock switch automatically shuts off power to the unit when the blower compartment access panel is removed. (10)

- Gas piping and electrical inlets are provided on both sides of the cabinet. (11)

Return Air Entry:

- For bottom/end return-air entry for upflow/horizontal applications, remove the furnished bottom seal panel from the cabinet.

- For side return-air entry (upflow applications only), corners are marked on either side of the cabinet for return air cut-outs.

NOTE: 60C and 60D size units that require air volumes over 1800 cfm must have one of the following:

- Single side return air with transition, to accommodate a 20 x 25 x 1 in. cleanable air filter. Required to maintain proper air velocity.

- Single side return air with Optional Return Air Base.

- Bottom return air.

- Return air from both sides.

- Bottom and one side return air.

See Blower Performance Tables for additional information.

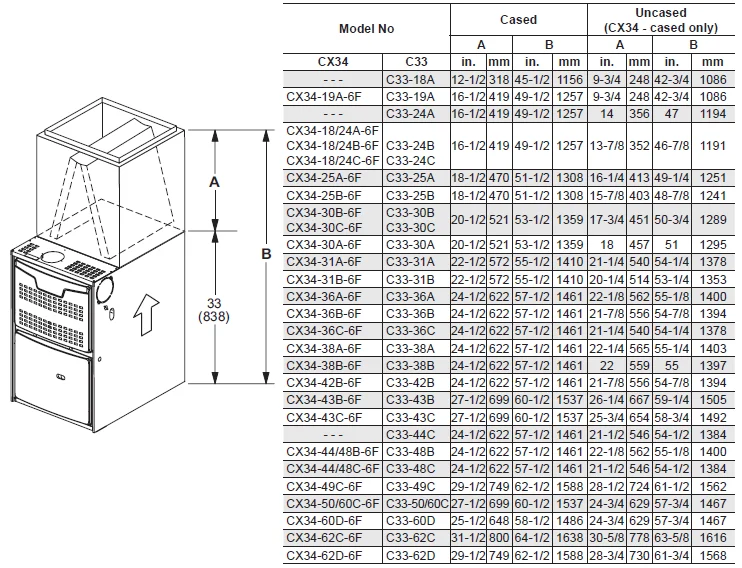

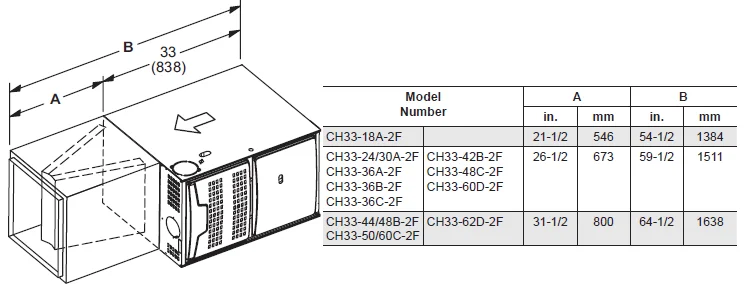

Coil Match-up

All furnaces exactly match C33 and CX34 cased upflow indoor coils and CH33 horizontal indoor coils with the same letter designation in the model number. No adaptor required. Engaging holes are furnished on the cabinet for alignment.

C33 uncased coils match furnaces without any overhang but require an optional adaptor base or field-fabricated transition to match furnace opening. See C33 coil bulletin for additional information.

OPTIONS

Horizontal Suspension Kit

- Provides suspension of the unit and coil in horizontal applications.

- Allows complete service access.

- Consists of corner-mounted hanging brackets with vibration isolators, a return air end support rail, and hardware for assembly.

- Metal hanging straps must be field-provided.

Return Air Base

- A field fabricated transition or Return Air Base is required when using an IAQ product higher than 14-3/16 in. installed next to the unit and serviced from the front. IAQ products higher than 20 in. require a field-fabricated transition.

- Base must be used for 60C and 60D models with air volumes over 1800 cfm in upflow applications when only one side return is required.

- The cabinet is shipped flat for easy field assembly and is pre-painted steel to match the furnace.

99% WINTER DESIGN TEMPERATURES FOR THE CONTIGUOUS UNITED STATES

This map is a necessarily generalized guide to temperatures in the contiguous United States. Temperatures shown for areas such as mountainous regions and large urban centers may not be accurate. The data used to develop this map were taken from the 1993 ASHRAE Fundamentals Handbook (Chapter 24, Table 1: Climate Conditions for the United States).

Reprinted with permission from NFPA 54: National Fuel Gas Code 1999, National Fire Protection Association, Quincy, MA 02269. This reprinted material is not the complete and official position of the National Fire Protection Association on the referenced subject, which is represented only by the standard in its entirety.

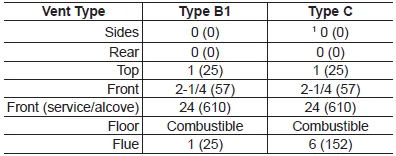

INSTALLATION CLEARANCES – INCHES (MM)

UPFLOW POSITION

NOTE − Air for combustion must conform to the methods outlined in the National Fuel Gas Code (NFPA 54/ANSI-Z223.1).

In the U.S., flue sizing must conform to the methods outlined in the current National Fuel Gas Code (NFPA 54/ANSI-Z223.1) or applicable provisions of local building codes.

1 Left side requires 4 in. if a single-wall vent is used on 14-1/2 in. cabinets, 2 in. on 17-1/2 in. cabinets.

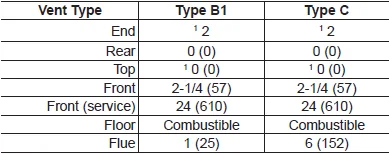

HORIZONTAL POSITION

NOTE − Air for combustion must conform to the methods outlined in the National Fuel Gas Code (NFPA 54/ANSI-Z223.1).

In the U.S., flue sizing must conform to the methods outlined in the current National Fuel Gas Code (NFPA 54/ANSI-Z223.1) or applicable provisions of local building codes.

1 Line contact installation permissible between jacket top or sides and building joists.

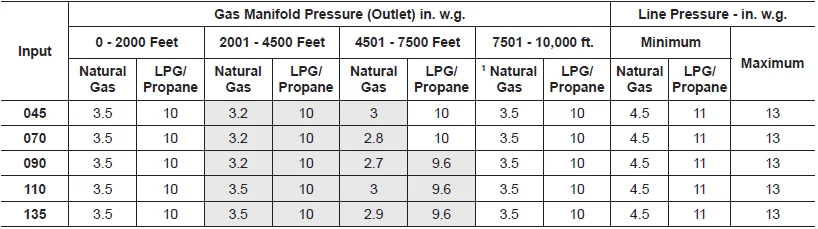

HIGH ALTITUDE DERATE

NOTE – Units may be installed at altitudes up to 2000 ft. above sea level without any modifications. At altitudes above 2000 ft., units must be derated to match information in the shaded areas shown below.

This is the only permissible derate for these units.

1 Natural Gas High Altitude Orifice Kit required.

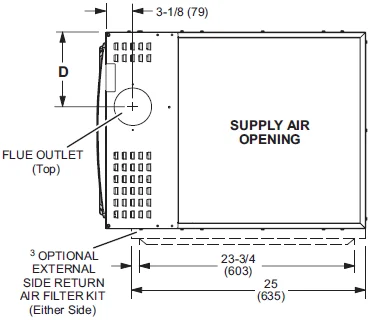

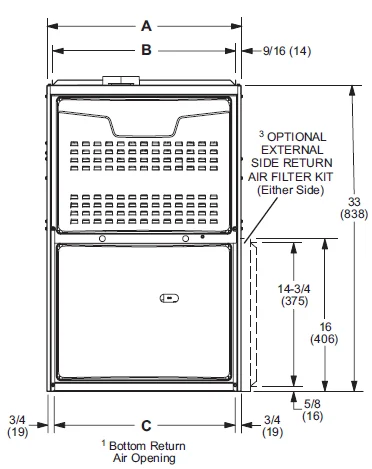

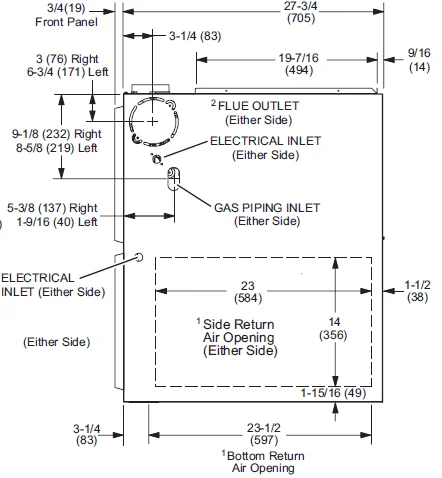

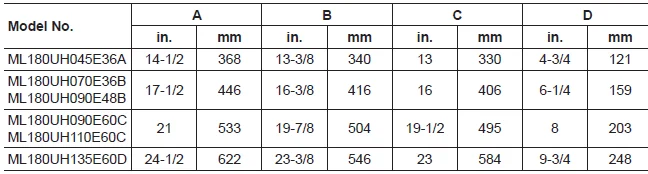

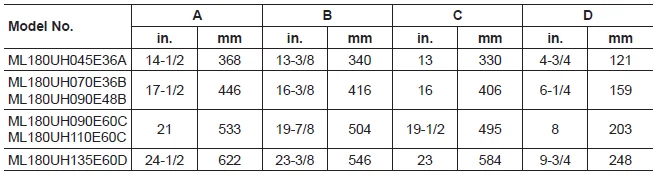

DIMENSIONS – INCHES (MM) – UPFLOW POSITION

1 NOTE: 60C and 60D size units that require air volumes over 1800 cfm must have one of the following:

- Single side return air with transition, to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) cleanable air filter. Required to maintain proper air velocity.

- Single side return air with optional Return Air Base.

- Bottom return air.

- Return air from both sides.

- Bottom and one side return air.See Blower Performance Tables for additional information.

2 The flue outlet may be horizontal, but the furnace must be vented vertically

3 Optional External Side Return Air Filter Kit is not for use with the optional Return Air Base.

TOP VIEW

FRONT VIEW

SIDE VIEW

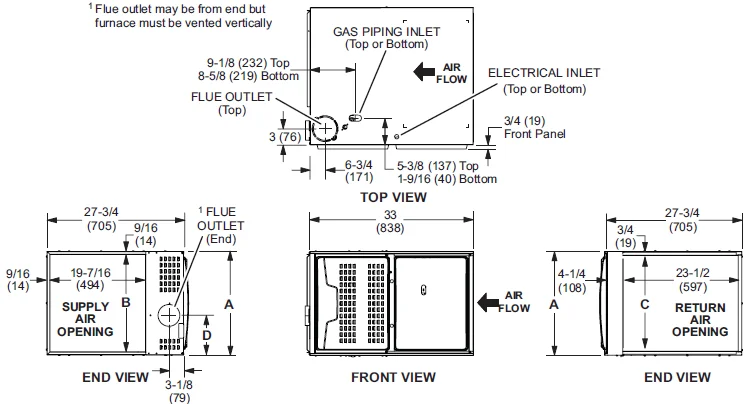

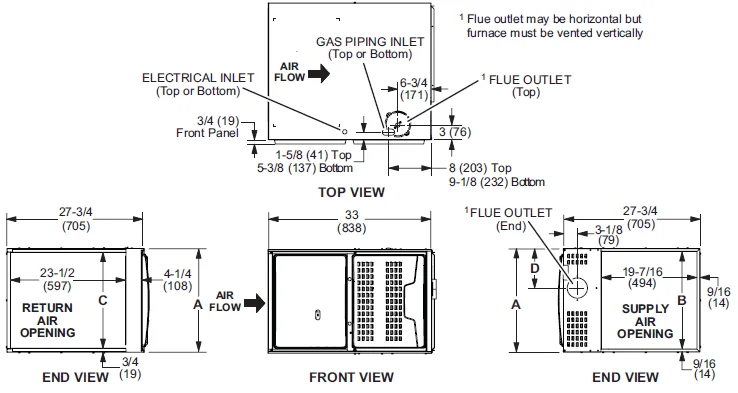

DIMENSIONS – INCHES (MM) – HORIZONTAL POSITION

LEFT-HAND AIR DISCHARGE

RIGHT-HAND AIR DISCHARGE

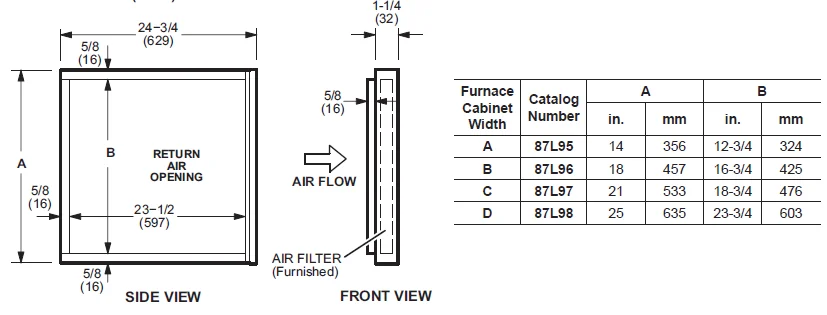

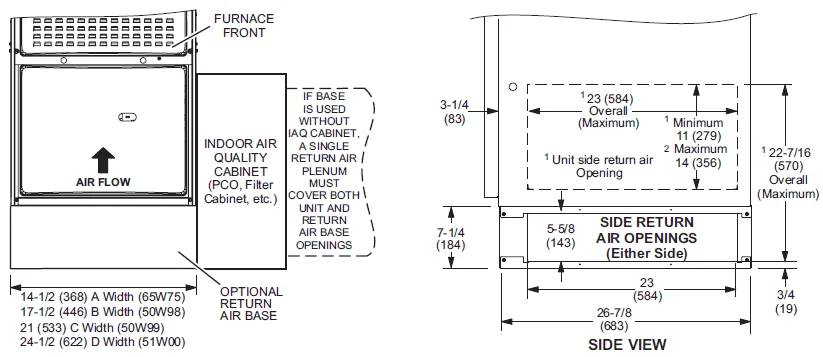

OPTIONAL ACCESSORY DIMENSIONS – INCHES (MM)

HORIZONTAL (END) FILTER KIT

Optional Return Air Base

(Upflow Applications Only – For use with A, B, C, and D cabinets)

NOTE- Optional Side Return Air Filter Kits are not for use with the Optional Return Air Base.

Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet. Minimum unit side return air opening dimensions for units requiring 1800 cfm or more of air (W x H): 23 x 11 in. (584 x 279 mm). The opening can be cut as needed to accommodate a plenum or IAQ cabinet while maintaining dimensions shown. Side return air openings must be cut in the field. There are cutting guides stenciled on the cabinet for the side return air opening. The size of the opening must not extend beyond the markings on the furnace cabinet.

To minimize pressure drop, the largest opening height possible, up to 14 in. (356 mm), is preferred.

DIMENSIONS – INCHES (MM) – FURNACE/COIL COMBINED DIMENSIONS

UPFLOW POSITION

HORIZONTAL POSITION

Contact Information

- Visit us at www.lennox.com

- For the latest technical information, www.lennoxdavenet.com

- Contact us at 1-800-4-LENNOX

For more Manuals by Lennox, visit ManualsLibraryy

Lennox MERIT ML180UH Horizontal Gas Furnace-FAQs

How do I troubleshoot my Lennox furnace?

Check the thermostat settings and batteries first. Inspect the power supply and reset the circuit breaker if tripped. Examine the ignitor and flame sensor for dirt or damage, and gently clean the flame sensor if needed.

How do I read a Lennox furnace error code?

Locate the LED light on the furnace and note its blinking pattern. Remove the front cover to find the error code list and match the blinks to identify the issue.

What does a red or green flashing light mean?

A red blinking light often indicates overheating or a system fault. A green flashing light usually signals normal operation or system readiness.

How often should I service my Lennox furnace?

Annual maintenance is recommended to keep the furnace running efficiently and prevent potential issues.

What is the efficiency rating of the ML180UH?

The ML180UH has an AFUE efficiency of 80%, suitable for most residential applications.

How much heat does the Lennox ML180 provide?

It delivers 66,000 BTU input heat.

Can I change the furnace filter myself?

Yes. Ensure the power is off before removing the old filter and inserting the new one. Make sure it is oriented correctly according to airflow direction arrows.

What are common signs of a dirty filter?

Signs include uneven heating, higher energy bills, frequent cycling, or visible dust buildup on the filter.