McGRAW 57567 3 Gallon Oil Free Portable Air Compressor

IMPORTANT SAFETY INFORMATION

General Safety Warnings

WARNING: Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric shock, fire, and/or serious injury. Save all warnings and instructions for future reference.

The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors that cannot be built into this product but must be supplied by the operator.

Work area safety

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate the Compressor in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Compressor motors produce sparks, which may ignite the dust or fumes.

- Keep children and bystanders away from an operating compressor.

Electrical safety

- Compressor plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with grounded compressors. Standard plugs and matching outlets will reduce the risk of electric shock.

- Do not expose compressor to rain or wet conditions. Water entering a compressor will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord to unplug the compressor. Keep cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing, and use common sense when operating this compressor. Do not use this compressor while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating a compressor may result in serious personal injury.

- Use personal protective equipment. Always wear ANSI-approved eye protection during setup and use.

- Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source or moving the compressor.

Compressor use and care

- Do not use the compressor if the switch does not turn it on and off. Any compressor that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the compressor. Such preventive safety measures reduce the risk of starting the compressor accidentally.

- Store an idle compressor out of the reach of children and do not allow persons unfamiliar with the compressor or these instructions to operate it. A compressor is dangerous in the hands of untrained users.

- Maintain the compressor. Keep the compressor clean for better and safer performance. Follow the instructions for lubricating and changing accessories. Keep dry, clean, and free from oil and grease. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the compressor’s operation. If damaged, have the compressor repaired before use. Many accidents are caused by a poorly maintained compressor.

- Use the compressor in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the compressor for operations different from those intended could result in a hazardous situation.

Service

Have your compressor serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the compressor is maintained.

WARNING: TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Turn the Power Switch “OFF” and unplug the Air Compressor from its electrical outlet before assembling or making any adjustments to the compressor.

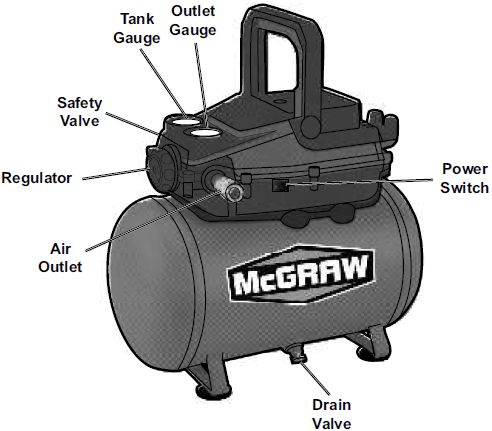

Functions

For technical questions, please call 1-888-866-5797.

Breaking in the Compressor

- Turn the Power Switch OFF and unplug the Power Cord.

- Fully open Regulator.

- Fully open Drain Valve.

- Plug in Power Cord.

- Turn the Power Switch ON.

- Let the unit run for 15 minutes. Air will expel freely through the Drain Valve.

- Turn the Power Switch OFF.

- Unplug the Power Cord and close the Drain Valve.

Air Connection Setup

- Connect 1/4! air hose with an Industrial (M-style) plug (sold separately) to the Air Outlet. The air hose must be long enough to reach the work area with enough extra length to allow free movement while working.

- Consult the air tool’s manual for needed accessories.

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual, including all text under subheadings therein, before setting up or use of this product.

Compressor Area Set Up

- Designate a work area that is clean and well-lit. The work area must not allow access by children or pets to prevent injury.

- Locate the Compressor on a flat level surface to ensure proper pump lubrication and to prevent damage to the unit. Keep at least 12! of space around the unit to allow air circulation.

- Route the power cord from the compressor to the grounded wall outlet along a safe path without creating a tripping hazard or exposing the power cord to possible damage.

General Operation

- Close the Drain Valve.

- Plug the Power Cord into a grounded 120 VAC electrical outlet.

- Turn the Power Switch ON.

- Allow the Air Compressor to build up pressure until it cycles off.

Note: At the beginning of the day’s first use of the Air Compressor, check for air leaks by applying soapy water to connections while the Air Compressor is pumping and after pressure cutout. Look for air bubbles. If air bubbles are present at connections, tighten connections. Do not use the Air Compressor unless all connections are airtight; the extra air leaking out will cause the compressor to operate too often, increasing wear on the compressor.

- Adjust the Regulator Knob so that the air output is enough to properly power the tool, but the output will not exceed the tool’s maximum air pressure at any time. Turn the knob clockwise to increase the pressure and counter-clockwise to decrease pressure. Adjust the pressure gradually while checking the air output gauge to set the pressure.

- Make sure the air tool’s throttle or switch is in the off position. Connect the air tool to the air hose.

- Use the air tool as needed.

- After the job is complete, turn the Power Switch OFF.

- Unplug the Air Compressor.

- Bleed air from the tool, then disconnect the tool.

- Drain Tank according to Draining Moisture from the Tank.

- Clean, then store the Air Compressor indoors.

Maintenance and Servicing

Procedures not specifically explained in this manual must be performed only by a qualified technician.

WARNING

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION: Turn the Power Switch “OFF” and unplug the Compressor from its electrical outlet before performing any inspection, maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY FROM COMPRESSOR FAILURE: Do not use damaged equipment. If abnormal noise or vibration occurs, have the problem corrected before further use.

Cleaning, Maintenance, and Lubrication

- BEFORE EACH USE, inspect the general condition of the air compressor. Check for:

- loose hardware,

- misalignment or binding of moving parts,

- cracked or broken parts,

- damaged electrical wiring, and

- any other condition that may affect its safe operation.

- AFTER USE, wipe the external surfaces of the compressor with a clean cloth.

- WARNING! TO PREVENT SERIOUS INJURY: If the supply cord of this compressor is damaged, it must be replaced only by a qualified service technician.

Draining Moisture from the Tank

The Moisture Drain is located under the Tank. It must be used daily to release all trapped air and moisture from the Tank. Doing this will eliminate condensation and prevent tank corrosion.

- Turn the Power Switch off.

- Place a collection pan under the Moisture Drain.

- Turn the Drain Valve to open it.

- When all the pressure and moisture is released, close the Drain Valve.

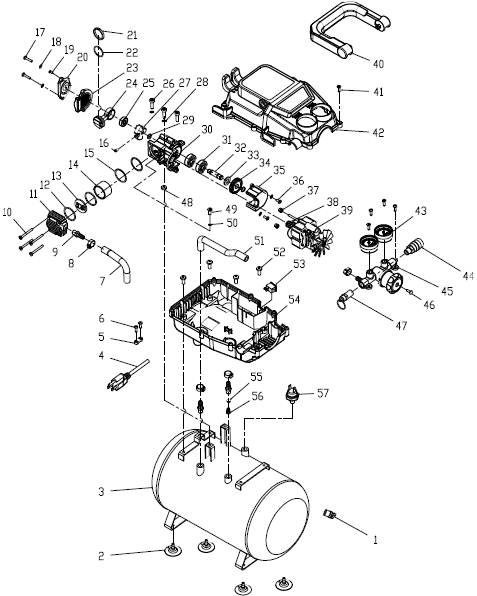

Parts List and Diagram

Parts List

| Part | Description | Qty |

| 1 | Drain Valve | 1 |

| 2 | Feet | 4 |

| 3 | Tank | 1 |

| 4 | Power Cord | 1 |

| 5 | Tension Disc | 1 |

| 6 | Screw ST4.2*15-F | 6 |

| 7 | Hose | 1 |

| 8 | Clamp | 4 |

| 9 | NPT 1/8 Two Way Connector | 3 |

| 10 | Screw M4*40 | 4 |

| 11 | Cylinder Cover | 1 |

| 12 | O-Ring | 2 |

| 13 | Valve Plate | 1 |

| 14 | Cylinder | 1 |

| 15 | Paper Gasket | 2 |

| 16 | Screw M5*10 | 1 |

| 17 | Screw M4*22 | 2 |

| 18 | Flat Washer | 4 |

| 19 | Screw ST2.9*10-C | 1 |

| 20 | Muffler Top Cover | 1 |

| 21 | Piston | 1 |

| 22 | O-Ring | 1 |

| 23 | Muffler Bottom Cover | 1 |

| 24 | Connecting Rod | 1 |

| 25 | Ball Bearing 608-2rs | 1 |

| 26 | Hex Screw M6*20 | 3 |

| 27 | Crankshaft | 1 |

| 28 | Flat Washer Ø6 | 2 |

| 29 | Circlip | 2 |

| Part | Description | Qty |

| 30 | Bracket | 1 |

| 31 | Ball Bearing 6200-2rs | 2 |

| 32 | Gear Shaft | 1 |

| 33 | Gasket | 1 |

| 34 | Gear | 1 |

| 35 | Gear Box Cover | 1 |

| 36 | Screw M4*13 | 2 |

| 37 | Hex Lock Nut M4 | 2 |

| 38 | Small Gear | 1 |

| 39 | Motor | 1 |

| 40 | Handle | 1 |

| 41 | Hex Socket Screw ST4.2*15-F | 8 |

| 42 | Upper Cover | 1 |

| 43 | Pressure Gauge | 2 |

| 44 | Coupler | 1 |

| 45 | Regulator Assembly | 1 |

| 46 | Hex Socket Screw ST4.2*10-F | 1 |

| 47 | Safety Valve | 1 |

| 48 | Shock Pad | 3 |

| 49 | Screw M5*10 | 1 |

| 50 | Washer Ø5 | 1 |

| 51 | Tube | 1 |

| 52 | Screw M6*15 | 4 |

| 53 | Power Switch | 1 |

| 54 | Bottom Cover | 1 |

| 55 | Ball | 1 |

| 56 | Spring | 1 |

| 57 | Pressure Switch | 1 |

Assembly Diagram

For more Manuals by McGRAW, visit ManualsLibraryy

McGRAW 57567 3 Gallon Oil Free Portable Air Compressor-FAQs

How are portable air compressors powered?

Portable air compressors are usually powered by a diesel engine, making them independent of electricity and built to withstand tough, dusty environments.

How does an oil-free air compressor operate?

An oil-free compressor uses external gears to synchronize its rotating screws. Since the rotors don’t touch, no lubrication is needed inside the compression chamber, resulting in clean, oil-free compressed air.

What is a compressed air battery and how does it work?

A compressed air battery stores energy by using sources like sunlight to compress air. This stored energy is later converted back into electricity when needed, even if the original energy source is unavailable.

Can an oil-free air compressor run non-stop?

Oil-free air compressors are not typically designed for continuous operation. However, because they require less maintenance, their overall service lifespan can be comparable to oil-lubricated compressors.

What does “free air delivery” (FAD) mean in compressors?

Free Air Delivery (FAD) refers to the amount of air a compressor delivers, adjusted to standard atmospheric conditions, factoring in temperature, pressure, and humidity.

What is the primary function of a compressor?

A compressor reduces the volume of gas or air and increases its pressure, making it useful across industries, agriculture, and household applications.

What is the main purpose of an air compressor?

The main role of an air compressor is to generate and store compressed air, which is then used as energy to power a wide variety of tools, machinery, and industrial processes.

How much energy is needed to compress air?

It typically takes about 10 units of electrical energy input to a compressor to produce 1 unit of mechanical energy output for powering equipment like air motors or pumps.