Pacific Zuma Strength Training fitness Equipment

Important Safety Instructions for Using the Equipment

Before beginning any fitness program, you should obtain a complete physical examination from your physician. When using exercise equipment, you should always take basic precautions, including the following:

- Read all instructions before using the Zuma equipment. These instructions are written to ensure your safety and to protect the unit.

- Do not allow children on or near the equipment.

- Use the equipment only for its intended purpose as described in this guide. Do not use accessory attachments that are not recommended by the manufacturer: such attachments might cause injuries.

- Wear proper exercise clothing and shoes for your workout—no loose clothing.

- Use care when getting on or off the unit.

- Do not overexert yourself or work to exhaustion.

- If you feel any pain or abnormal symptoms, stop your workout immediately and consult your physician.

- Never operate the unit when it has been dropped or damaged. Return the equipment to a service center for examination and repair.

- Never drop or insert objects into any opening. Keep your hands away from moving parts.

- Always check the unit and its cables before each use. Make sure that all fasteners and cables are secure and in good working condition.

- Do not use outdoors.

Personal Safety During Assembly

- It is strongly recommended that a qualified dealer assemble the equipment. Assistance is required.

- Read each step in the assembly instructions and follow the steps in sequence. Do not skip ahead. If you skip ahead, you may learn later that you have to disassemble components and that you may have damaged the equipment.

- Assemble and operate the Zuma on a solid, level surface. Locate the unit a few feet from the walls or furniture to provide easy access.

The Zuma is designed for your enjoyment. By following these precautions and using common sense, you will have many safe and pleasurable hours of healthful exercise with your new equipment.

Before You Begin

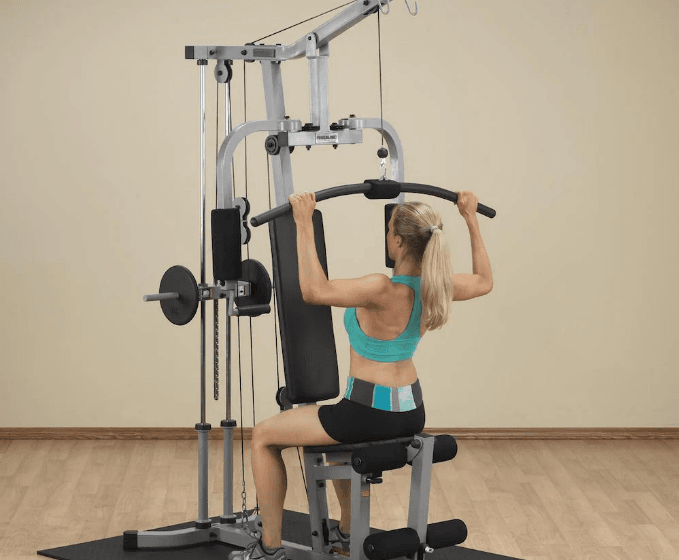

Thank you for purchasing the Zuma. This unit is part of the Pacific Fitness line of quality strength training machines, which let you target specific muscle groups to achieve better muscle tone and overall body conditioning. To maximize your use of the equipment, please study this guide thoroughly.

Unpacking the Equipment

The Zuma is carefully tested and inspected before shipment. Pacific Fitness ships the unit in several pieces that require assembly. Ask for assistance during the assembly process.

- Review the Installation Requirements found on the next page.

- When instructed to open a box, carefully unpack the pieces and lay them on the floor near the location where you plan to use the equipment. Be careful to open boxes and assemble components in the sequence presented in this manual. If any items are missing, contact the dealer from whom you purchased the unit or call 1-800-4-PRECOR for the dealer nearest you.

Optional Equipment

The Leg Press and Multi-Hip Options expand the workout options for the Zuma. You can purchase this equipment through your dealer.

Preparations

CAUTION: To set up this unit, you will need assistance. Do not attempt assembly by yourself. You must review and follow the instructions in this guide. If you do not assemble and use the Zuma according to the following guidelines, you could void the Precor limited warranty.

Required Tools

The tools that you need to obtain before assembling the unit include:

- ½-inch socket wrench

- ⁹⁄₁₆-inch socket wrench

- ¾-inch socket wrench

- ⁹⁄₁₆-inch box wrench

- ¾-inch box wrench

- Adjustable pliers or a crescent wrench

- Standard set of metric hex keys

- Rubber mallet

- Step stool

Installation Requirements

Follow these installation requirements when assembling the unit:

- Fill out and mail the limited warranty card. The warranty card is found on the back cover of this guide.

- Set up the Zuma on a solid, flat surface. A smooth, flat surface under the unit helps keep it level. A level unit has fewer malfunctions.

- Provide ample space around the machine. Open space around the machine allows for easier access.

- Insert all bolts in the same direction. For aesthetic purposes, insert all the bolts in the same direction unless specified (in text or illustrations) to do otherwise.

- Leave room for adjustments. Tighten fasteners (such as bolts, nuts, and screws), so the unit is stable, but leave room for adjustments. Do not fully tighten fasteners until instructed (in the steps) to do so.

Assembly Tips

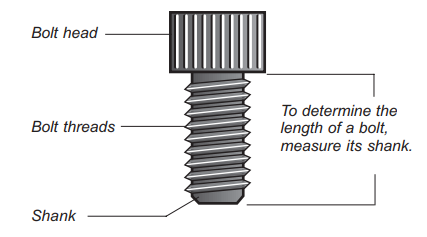

- A scale is provided at the bottom of every assembly instruction page. Use this scale to identify the correct size bolts and spacers. The head of a bolt is not used in measuring the length of a bolt.

Note: A few of the bolts used to assemble the Zuma are longer than 6 inches. You may want to use a measuring tape to identify the correct sizes accurately. To find out the length of a particular bolt, measure its shank (the long, narrow part beneath the head). Refer to the following diagram:

- Read all caution notes on each page before completing that step.

- Some pieces have extra holes that you will not use. Use only those holes indicated in the instructions and illustrations.

- While you may be able to assemble the Zuma by reading the illustrations only, refer to the text for important safety cautions and notes.

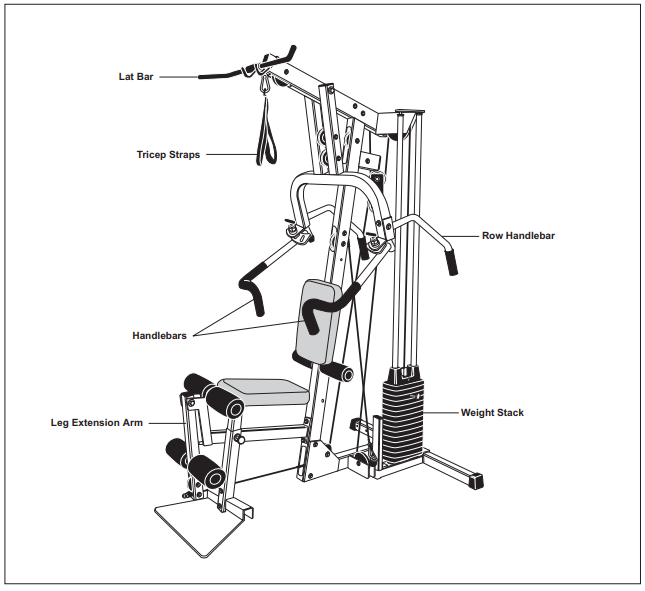

Assembly Instructions

The assembly of the Zuma takes professional installers about 1 hour to complete. If this is the first time you have assembled this type of equipment, plan on significantly more time. Professional installers are highly recommended! However, if you acquire the appropriate tools, obtain assistance, and follow the assembly steps sequentially, the process will take time, but it is fairly easy.

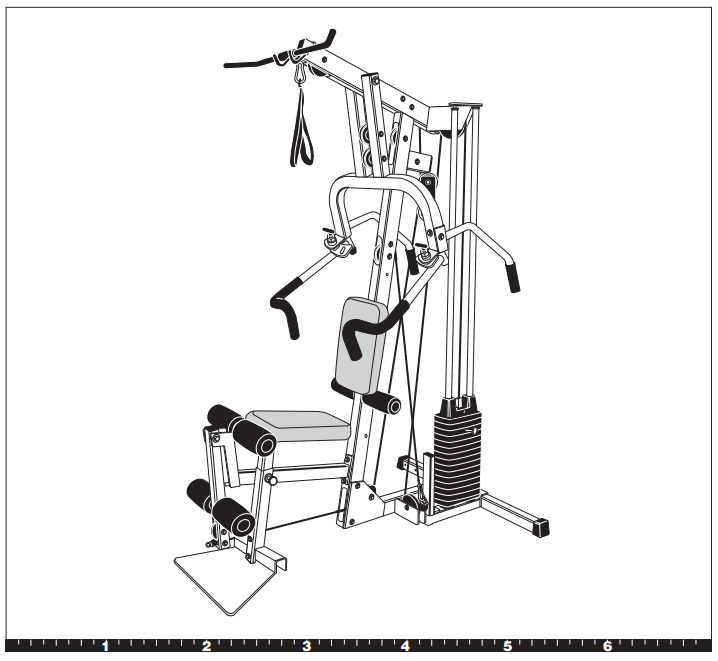

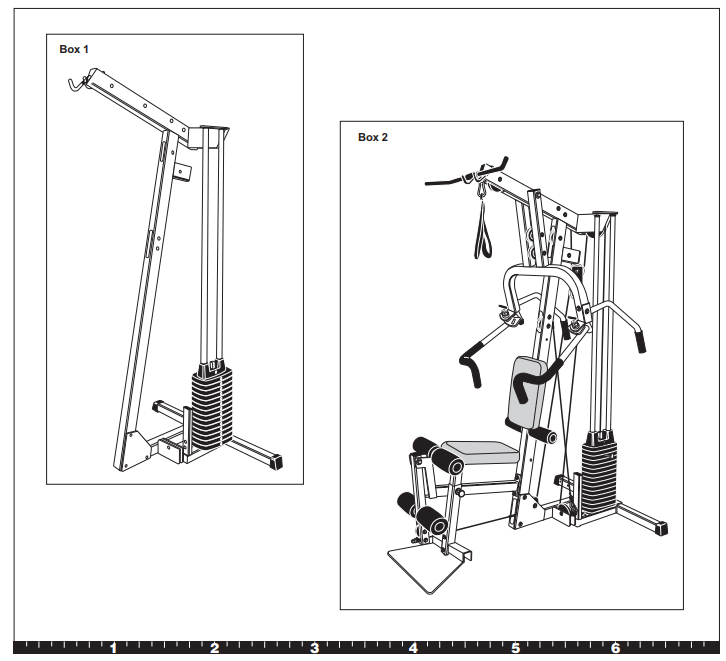

CAUTION: Obtain assistance! Do not attempt to assemble the Zuma by yourself. Review the Installation Requirements on page 6 before proceeding with the following steps. The Zuma comes in two boxes. (See the figure at the right.) Be careful to open boxes and assemble components in the sequence presented in this guide.

Note: With so many assembled parts, proper alignment and adjustment are critical. While tightening the nuts and bolts, ensure that you leave room for future adjustments. Do not fully tighten bolts until instructed to do so.

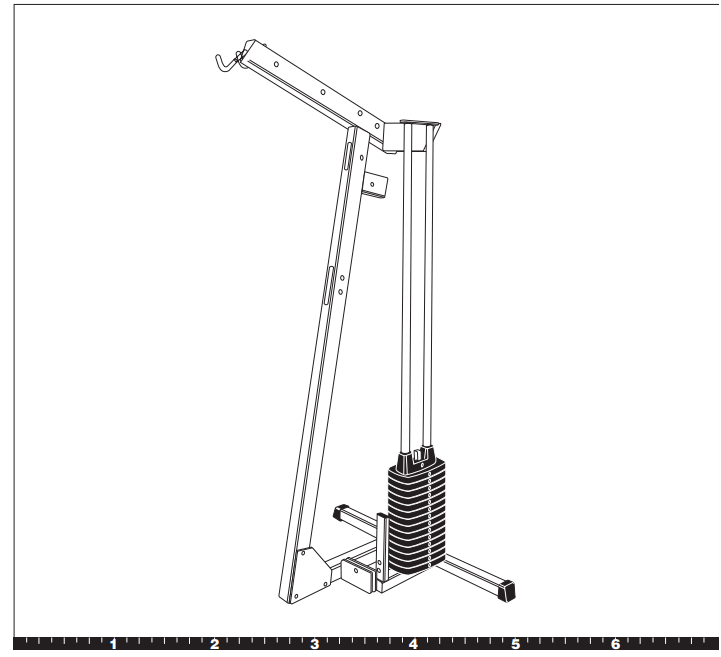

Open Box 1

Use the tie cutters to open the box. The illustration shows how the Zuma will look after you complete this section.

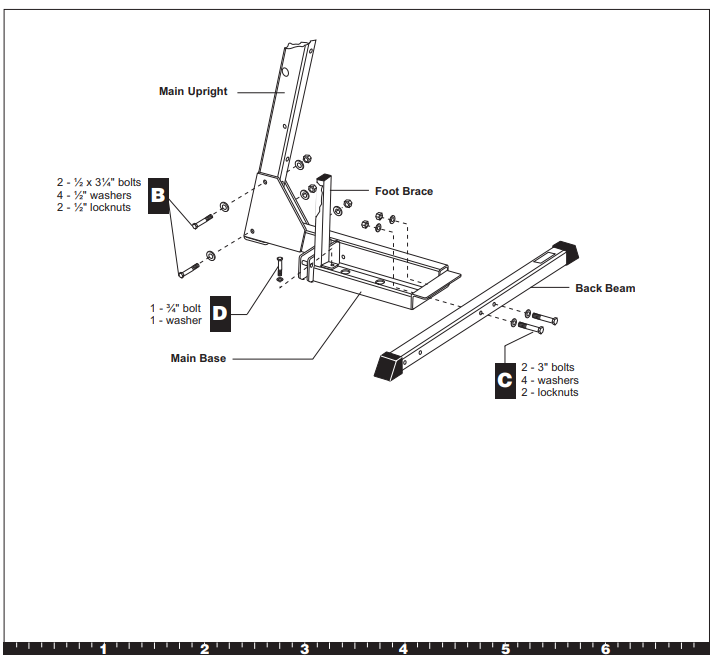

- Attach the Main Upright and Back Beam

- A. Lift the Main Upright into a vertical position.

- B. With one person holding the Main Upright steady, attach it to the Main Base using

- two ½-inch by 3¼-inch bolts

- four ½-inch washers

- two ½-inch locknuts

- Wrench tighten.

- C. Attach the Back Beam to the Main Base using

- two 3-inch bolts

- four washers

- two locknuts

Make sure the Warning label on the beam faces upward. Wrenches tighten the bolts.

- D. Attach the Foot Brace to the Main Base using

- one ¾-inch bolt

- one washer

- Wrench tighten.

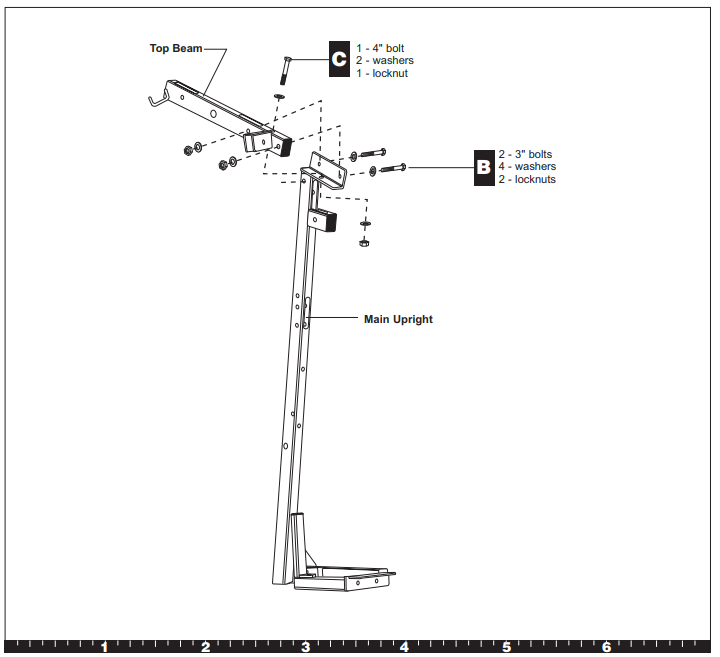

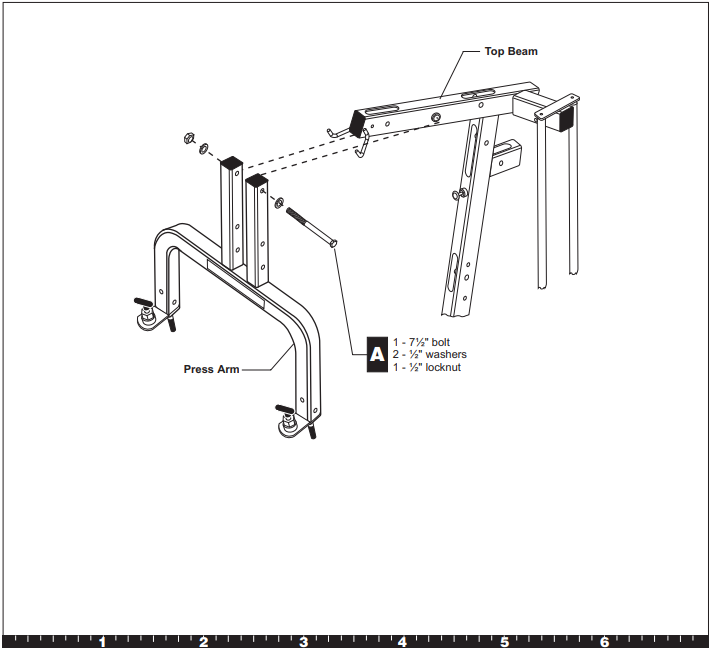

- Attach Top Beam

- A. Place the Top Beam on the Main Upright. Ensure the beam extends out as shown.

- B. Attach the Top Beam to the Main Upright from the side using

- two 3-inch bolts

- four washers

- two locknuts

- Finger tighten.

- C. Attach the Top Beam to the Main Upright from the

- top using

- One 4-inch bolt

- two washers

- one locknut

- Finger tighten.

- D. Wrench: tighten all bolts.

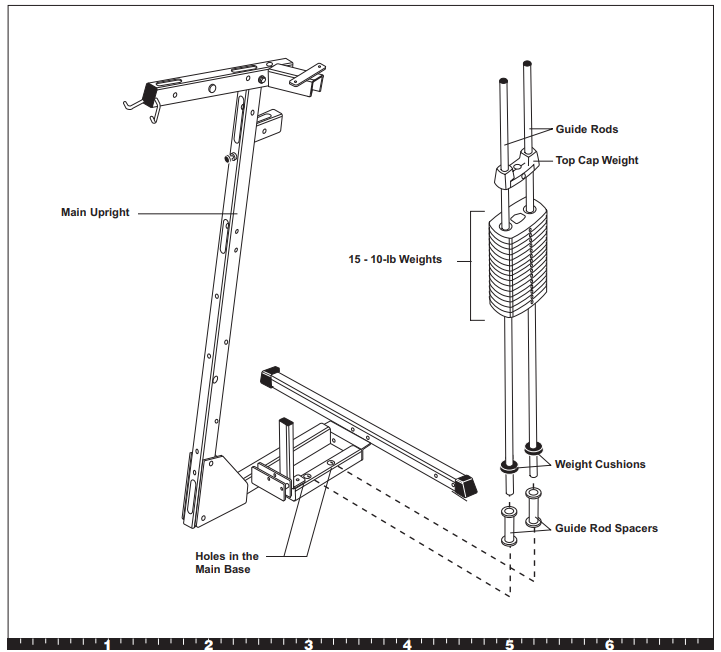

- Install Guide Rods

- A. Place the Guide Rods into the two holes in the Main Base. Until step 4 (when you attach them to the Top Beam), the Guide Rods will lean away from the base; however, they will not fall out. Use care not to get lubricant from the rods on your clothing or other parts of the machine.

- B. Place one Guide Rod Spacer and one Weight Cushion on each Guide Rod and allow it to slide down to the top of the Main Base.

- C. Add the fifteen 10-lb weights. Note the tab location for the weight decals (you will attach the decals later). Hold your finger over the plastic bushing in each weight to prevent the bushing from popping out.

CAUTION: The weights are heavy! Handle the weights carefully so as not to drop them or injure yourself. Pick up and place one weight at a time on the Guide Rods. Have someone hold the Guide Rods in place while you slide the weights on the stack. - D. Place the Top Cap Weight on the Guide Rods with the hole facing toward you. Allow it to slide to the weight stack.

- Secure Guide Rods

- A. Position the Guide Rods under the Guide Rod Bracket.

- B. Attach the Guide Rods to the bracket using two 1-inch bolts. Insert the bolts through the bracket and into the top of the Guide Rods as shown. Wrench tighten.

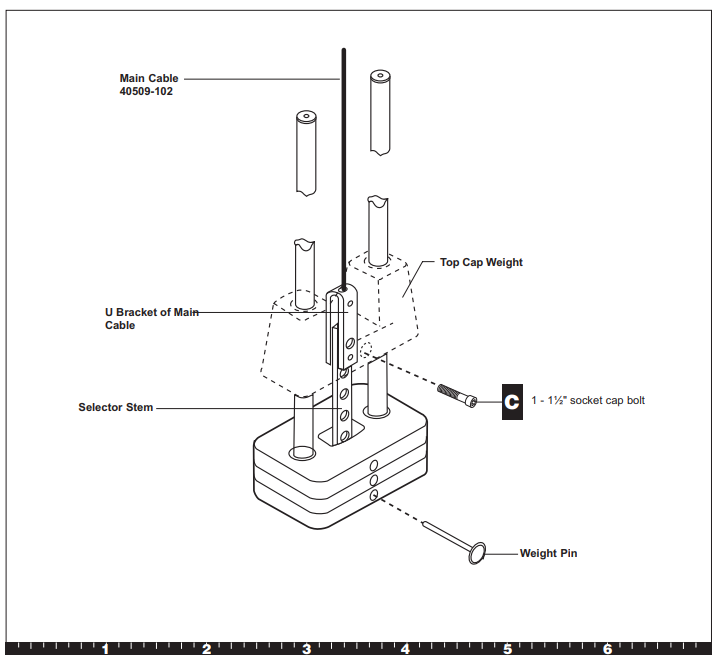

- Attach the U End of the Main Cable

- A. Insert the Selector Stem into the weight stack with the threaded hole at the top. Hold the Selector Stem with several holes above the Top Cap Weight. Insert the Weight Pin into the weight stack to suspend the Selector Stem.

- B. Place the U Bracket of Main Cable 40509-102 on the top of the Selector Stem.

- C. Align the holes in the top of the Selector Stem, U Bracket, and Top Cap Weight. Attach using a 1½-inch socket cap bolt. Wrench tighten.

- D. Remove the Weight Pin and lower the Top Cap Weight. This completes box 1. You may move the box out of the way. Leave the Main Cable loosely coiled on the floor; you will complete feeding it through the machine later.

- Open Box 2

- Use the tie cutters to open the box.

The illustration shows how the Zuma will look after you complete this section.

- Use the tie cutters to open the box.

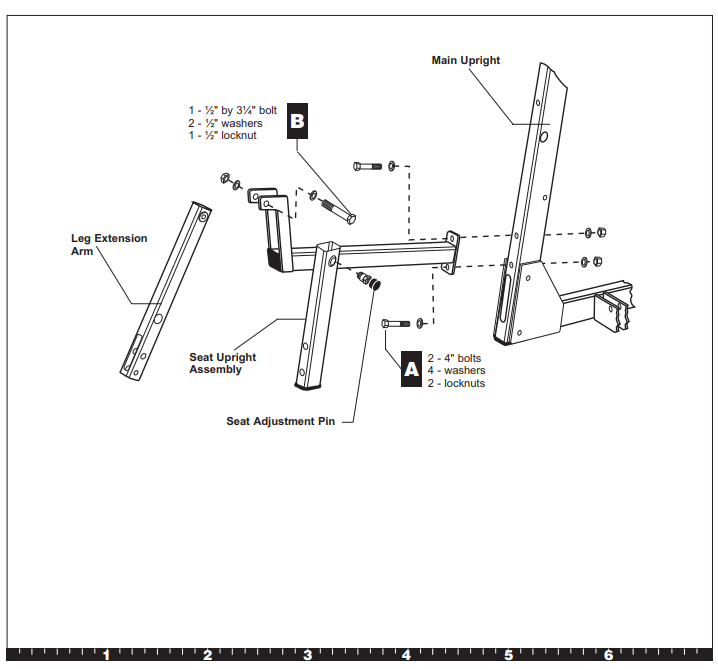

- Attach Seat Upright Assembly

- A. Attach the Seat Upright Assembly to the Main Upright using

- two 4-inch bolts

- four washers

- two locknuts

- Wrench tighten.

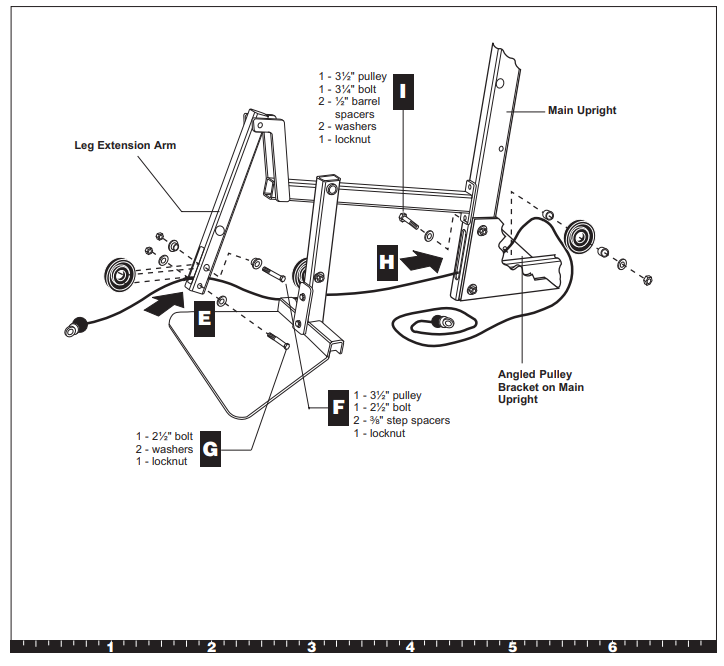

- B. Attach the Leg Extension Arm to the Seat Upright Assembly using

- one ½- by 3¼-inch bolt

- two ½-inch washers

- one ½-inch locknut

- Finger tighten, and then wrench tighten the bolt enough to allow free rotation of the Leg Extension Arm.

- C. Attach the seat adjustment pin to the Seat Upright Assembly (it screws in). Finger tighten.

- A. Attach the Seat Upright Assembly to the Main Upright using

- Attach Press Arm

- A. Attach the Press Arm to the Top Beam, with the label facing out, using

- one 7½-inch bolt

- two ½-inch washers

- one ½-inch locknut

- Wrench tighten enough to allow free rotation of the Press Arm.

- A. Attach the Press Arm to the Top Beam, with the label facing out, using

- Install Main Cable

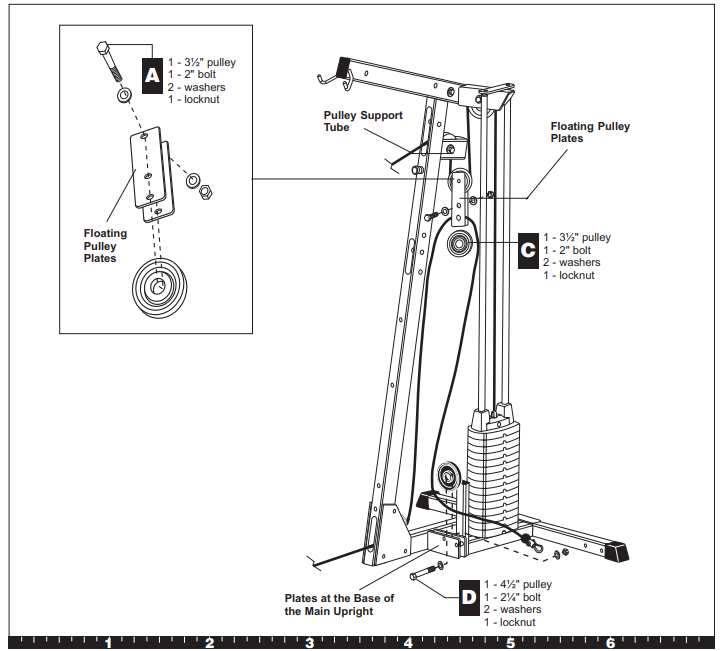

- A. From the back of the machine, pass the Main Cable 40509-102 connected to the Selector Stem over one 4½-inch pulley.

- B. Attach the pulley to the Guide Rod Arm of the Top Beam as shown, using

- One 2-inch bolt

- two washers

- one locknut

- Wrench tighten.

- C. Feed the Main Cable into the bottom hole of the Pulley Support Tube and out the top. Then, feed the Cable through the window in the Main Upright and allow it to hang freely. While this cabling may look strange, it will make sense later.

- D. Wrap the Main Cable over one 3½-inch pulley and mount the pulley on the top of the Pulley Support Tube using

- one 2¾-inch bolt

- two ½-inch step spacers

- one locknut

- Wrench tighten.

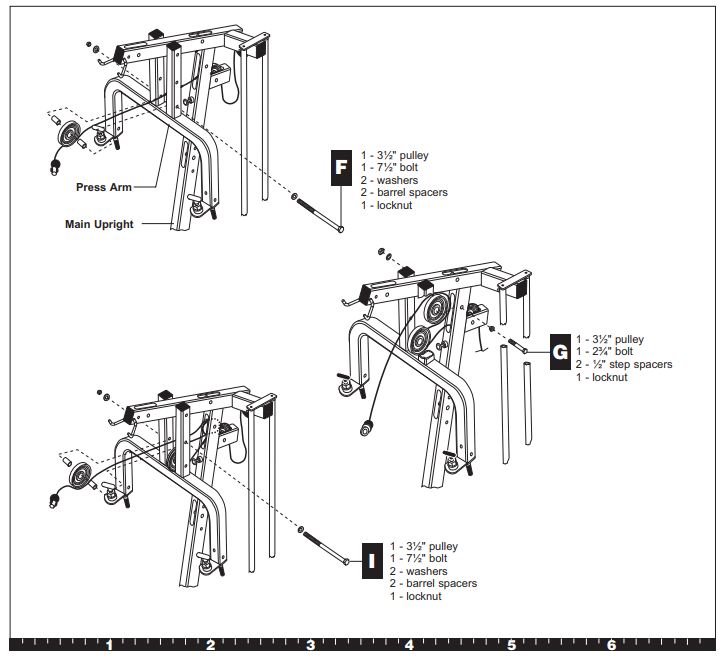

- E. Feed Main Cable 40509-102 through the two vertical bars in the Press Arm and allow it to hang.

- F. Attach one 3½-inch pulley in the Press Arm over the Cable using

- one 7½-inch bolt

- two washers

- Two-barrel spacers

- one locknut

- Finger tighten.

- G. Attach one 3½-inch pulley in the top window of the Main Upright using

- one 2¾-inch bolt

- two ½-inch step spacers

- one locknut

- Finger tighten.

- H. Feed the Cable over the top of the pulley installed in step F, then feed it under the pulley installed in step G and back over the top. Pull the Cable back through the two vertical bars in the Press Arm.

- I. Attach one 3½-inch pulley in the Press Arm, over the pulley installed in step F, and with the Cable passing underneath, using

- one 7½-inch bolt

- two washers

- Two-barrel spacers

- one locknut

Ensure the Cable is below the pulley. Finger tighten.

- J. Wrench tighten all bolts from steps F, G, and I (bolts for the three pulleys you just installed).

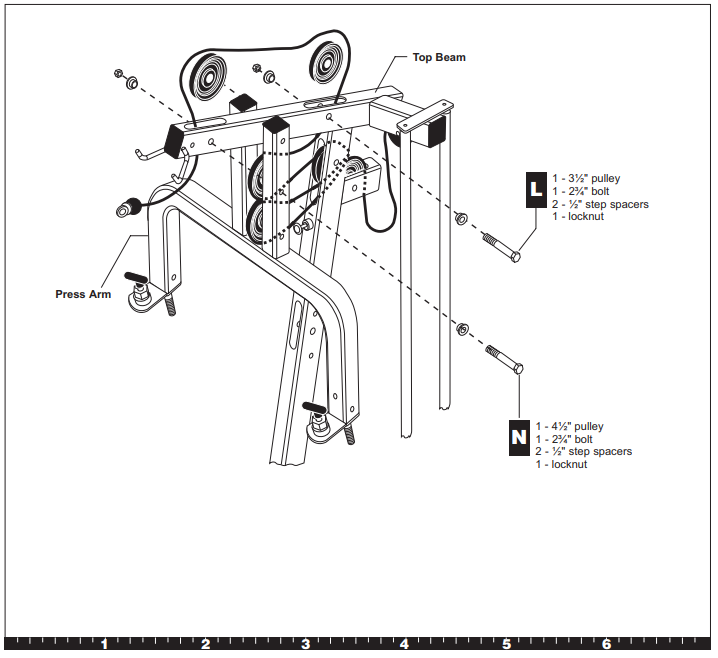

- K. Wrap the Main Cable up and over the pulley installed in step I and feed it up through the back window in the Top Beam.

- L. Attach one 3½-inch pulley over the Cable and in the back window of the Top Beam using

- one 2¾-inch bolt

- two ½-inch step spacers

- one locknut

- Make sure the Cable is underneath the pulley.

- Wrench tighten.

- M. Wrap the Cable over the pulley and feed it through the front window of the Top Beam.

- N. Attach one 4½-inch pulley under the Cable and in the front window of the Top Beam using

- one 2¾-inch bolt,

- two ½-inch step spacers

- one locknut

- Wrench tighten.

- G. Attach one 3½-inch pulley in the top window of the Main Upright using

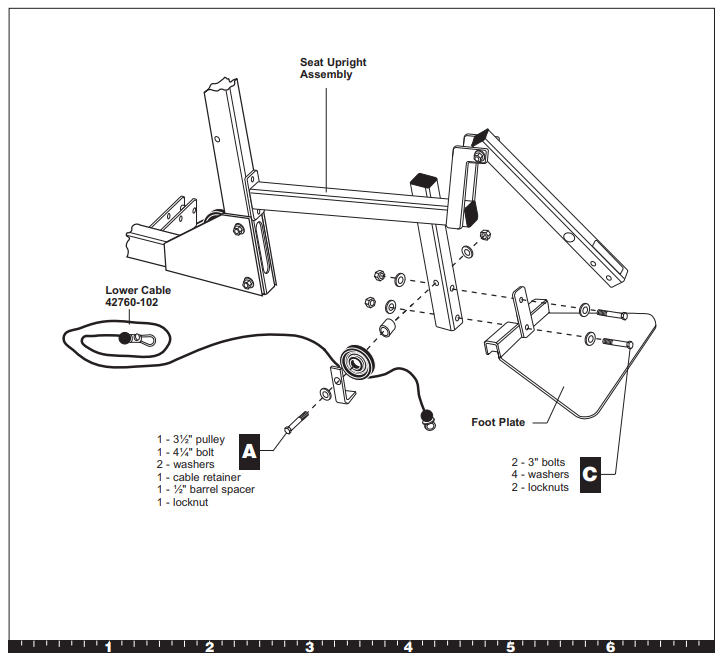

- Install Lower Cable in Seat Upright Assembly

- A. Attach the Foot Plate and one 3½-inch pulley to the Seat Upright Assembly through the top hole using

- one 4¼-inch bolt

- two washers

- One cable retainer

- one ½-inch barrel spacer

- one locknut

- Finger tighten.

- B. Slip the Lower Cable 42760-102 around the pulley.

- C. Attach the Foot Plate to the Seat Upright Assembly using

- two 3-inch bolts

- four washers

- two locknuts

- Finger tighten.

- D. Wrench, tighten the top and bottom bolts.

- E. Feed one end of the Lower Cable through the window in the Leg Extension Arm.

- A. Attach the Foot Plate and one 3½-inch pulley to the Seat Upright Assembly through the top hole using

- Complete Lower Cable Installation

- A. Attach one 3½-inch pulley to the Floating Pulley Plates to the end with the single hole as shown using

- one 2-inch bolt

- two washers

- one locknut

- Finger tighten.

- B. Hang the pulley in the Floating Pulley Plates on the Main Cable where it enters the Pulley Support Tube.

- C. Wrap the Lower Cable over one 3½-inch pulley and attach the pulley to the Floating Pulley Plates in the appropriate hole, using

- one 2-inch bolt

- two washers

- one locknut

- Avoid any twists in the Cable. Wrench tighten.

Note: The Floating Pulley Plates have two holes where the pulley can be installed. Generally, you would use the upper hole. However, if you purchased the Leg Press Option and are installing it, use the lower hole.

- D. Wrap the Lower Cable under one 4½-inch pulley and attach the pulley between the two plates at the base of the Main Upright using

- one 2¼-inch bolt

- two washers

- one locknut

- Finger tighten. Make sure that the Cable passes between the pulley and the cable retainer pin.

- A. Attach one 3½-inch pulley to the Floating Pulley Plates to the end with the single hole as shown using

- Wrench tighten.

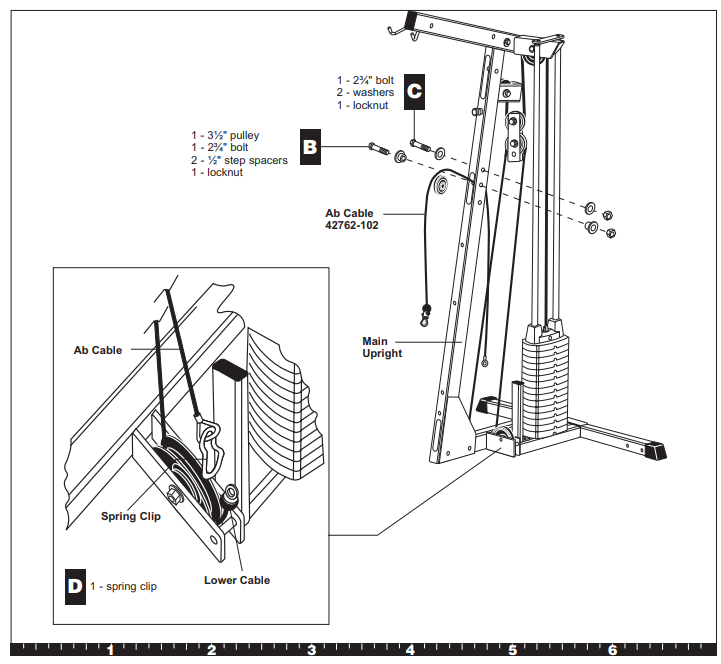

- Install AB cable

- A. Using the short Ab Cable 42762-102, feed the loop end with the ball through the middle window in the Main Upright, feeding it from the back to the front.

- B. Place one 3½-inch pulley in the window of the Main Upright under the Cable, then attach the pulley using

- one 2¾-inch bolt

- two ½-inch step spacers

- one locknut

- Make sure the Ab Cable goes over the pulley.

- Wrench tighten.

- C. Insert a bolt over the pulley in the Main Upright to create a cable retainer using

- one 2¾-inch bolt

- two washers

- one locknut

- Make sure that the Cable passes between the pulley and the bolt. Wrench tighten.

- D. Attach the Cable, using the end without a ball, to the Lower Cable using one spring clip. Make sure that the cables do not wrap around each other.

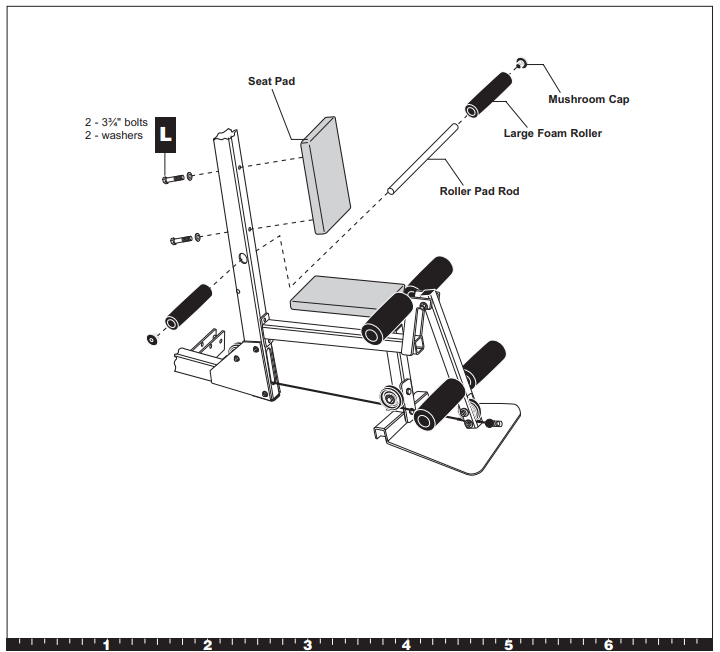

- Install Seat and Rollers

- A. Attach the Seat Pad to the Seat Stem using

- two 2¼-inch bolts

- two washers

- Wrench tighten.

- You can use either pad provided; they are the same size. Also, you may want to make sure that the seam on the pad faces toward the back, away from the Roller Pad Rod Holder.

- B. Insert the Seat Stem into the Seat Upright Assembly. Pull out the seat adjustment pin to insert the stem. Also, make sure that the Roller Pad Rod Holder faces toward the front.

- C. Slide a large Foam Roller completely on one end of the Roller Pad Rod, then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- D. Insert the Roller Pad Rod through the holder on the Seat Stem.

- E. Slide a large Foam Roller on the other end of the Roller Pad Rod, then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- F. Repeat for the Leg Extension Arm. Slide a large Foam Roller completely on one end of a Roller Pad Rod, then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- G. Insert the Roller Pad Rod through the hole in the Leg Extension Arm (near the pulley).

- H. Slide a large Foam Roller on the other end of the Roller Pad Rod, and then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- Again, repeat for the Main Upright. Slide a small Foam Roller completely on one end of a Roller Pad Rod, then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- J. Insert the Roller Pad Rod through the hole in the Main Upright above the previously installed Seat Pad.

- K. Slide a small Foam Roller on the other end of the Roller Pad Rod, then secure it in place by pounding one mushroom cap in the end using the rubber mallet.

- L. Attach the other Seat Pad to the Main Upright using

- two 3¾-inch bolts

- two washers

- Wrench tighten. You may want to make sure that the seam on the pad faces down.

- A. Attach the Seat Pad to the Seat Stem using

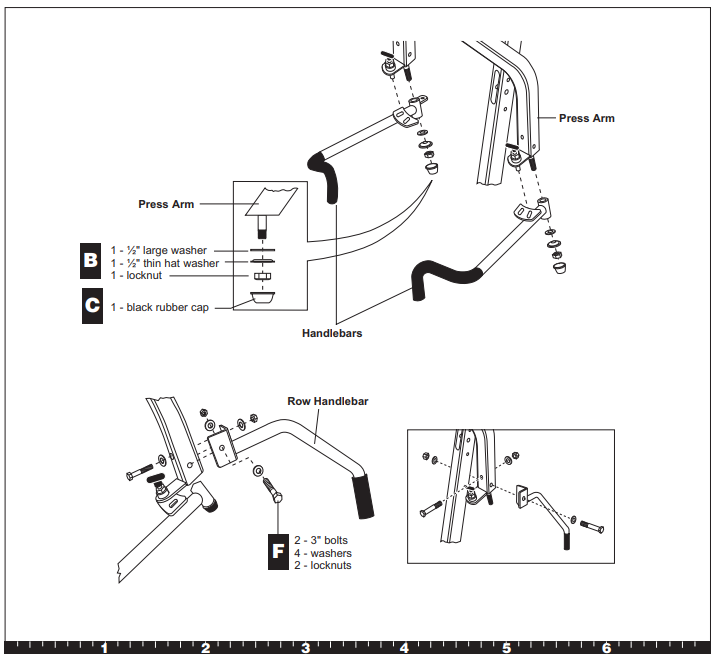

- Attach Handlebars

- A. Slide a Handlebar in place on the Press Arm. Handlebars curve inward; choose the correct handlebars.

- B. Attach the Handlebar using

- one ½-inch large washer

- one ½-inch thin hat washer

- one locknut

- Place the thin hat washer so it cups upward. Wrench tighten, still allowing movement.

- C. Cover the end of the bolt with the black rubber cap. Consider using the mallet to pound on the cap.

- D. Repeat steps A through C for the other Handlebar.

- E. Place a Row Handlebar on the Press Arm. Row Handlebars curve to the right or the left from the mounting plate; choose the correct Row Handlebar.

- F. Attach the Row Handlebar using

- two 3-inch bolts

- four washers

- two locknuts

Insert one bolt from the back and one from the side. Finger tighten both bolts, and then wrench tighten.

- G. Repeat steps E and F for the other Row Handlebar.

For more manuals by Pacific Fitness, visit ManualsLibraryy

Pacific Zuma Strength Training fitness Equipment-FAQs

What are the most common pieces of strength training equipment?

Free Weights (dumbbells, barbells, kettlebells)

Machines (cable machines, leg press, Smith machine)

Resistance Bands

Medicine Balls

Stability Balls

Pull-Up Bars & Dip Stands

Benches (adjustable/flat/incline)

What is the difference between free weights and machines?

Free weights (dumbbells, barbells) require balance & engage stabilizer muscles.

Machines guide movement, reducing injury risk but limiting functional strength.

Can I build strength without equipment?

Yes! Bodyweight exercises (calisthenics) like:

Push-ups

Pull-ups

Squats

Planks

Lunges

What is calisthenics?

A form of strength training using body weight (e.g., push-ups, burpees) instead of equipment.

What’s best for beginners?

Dumbbells (adjustable)

Resistance bands (versatile & portable)

Kettlebells (full-body workouts)

What equipment measures strength?

Hand-held dynamometers (grip strength)

Barbell max lifts (bench press, deadlift)

Does Fitness First provide workout gear?

Most locations offer towels & locker amenities, but bring your own workout clothes.

How do I clean gym equipment?

Use Simple Green or disinfectant wipes.

Wipe down handles, seats, and screens after use.

What counts as strength training?

Any exercise using resistance (weights, bands, body weight) to build muscle.