Profitec GO Espresso Machine

PRODUCT DELIVERY

- 1 portafilter 2 spouts

- 1 filter 1 cup

- 1 filter 2 cups

- 1 blind filter

- 1 coffee tamper

- 1 cleaning brush

- 1 user manual

GENERAL ADVICE

General safety notes

- Make sure that the local main supply voltage corresponds to the information given on the type plate on the front panel of the espresso machine.

- The installation of the machine should be carried out by authorised specialists according to the instructions in chapter 4.

- Plug the machine into a grounded socket only and do not leave it unattended.

- Make sure the machine is disconnected from the power supply during service and when replacing parts.

- Do not roll or bend the power cord.

- If the supply cord is damaged, it must be replaced by a service agent or similarly qualified persons in order to avoid a hazard.

- Do not use an extension cord/or a multiple socket.

- Place the machine on an even and stable surface. Only use the machine on a water-resistant surface.

- Never place the machine on hot surfaces.

- Do not place the machine in a cabinet when in use.

- Never submerse the machine in water; do not operate the machine with wet hands.

- Make sure that no liquid gets on the power plug of the machine or on the socket.

- The machine should only be used by experienced adult persons.

- The machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

- Cleaning and user maintenance shall not be made by children without supervision

- Do not expose the machine to inclement weather (frost, snow, rain) and do not use it outdoors.

- Keep the packing out of reach of children.

- Only use original spare parts.

- Water tank machines or machines in water tank use: Do not operate the machine with carbonated water, but with soft, potable water.

- Do not operate the machine without water.

- Please note that the surface of the machine, in particular the brew group and the steam wand, become hot during operation and are still hot after operation. There is a risk of injury.

If you have any further questions or if you require any further information, please contact your specialized dealer before starting up the espresso coffee machine. Our machines comply with the relevant safety regulations. Any repairs or changes of components must be carried out by an authorized specialty dealer. In case of non-observance, the manufacturer does not assume liability and is not liable to recourse. See 1 for your specialized dealer’s contact details. Authorized service points can be found in our dealer search on www.profitec-espresso.com.

Important

You should use water with a max. hardness of 4° dH in order to protect your machine from lime scale damage. When necessary, make use of a water softener/water filter cartridge to reach an adequate degree of hardness. If these measures are insufficient, a prophylactic descaling of the machine may be necessary. Contact your specialized dealer before undertaking this measure. An already calcified machine may only be descaled by your specialized dealer because a partial disassembly of the boiler and the tubing may be necessary to prevent the system from being blocked by lime residues. A late descaling can cause substantial damage to the machine. You can also use a water filter cartridge (item no. 89445 K) in the water tank (under the water tank lid) to help reduce limescale in the water and protect your espresso machine from limescale.

Proper use

The GO is designed to be used for the preparation of coffee and steam only. The machine is not intended for commercial use. Use of the machine other than for the above-mentioned purpose is not recommended. The manufacturer cannot be held responsible for damages due to unsuitable use of the machine and is not liable to recourse.

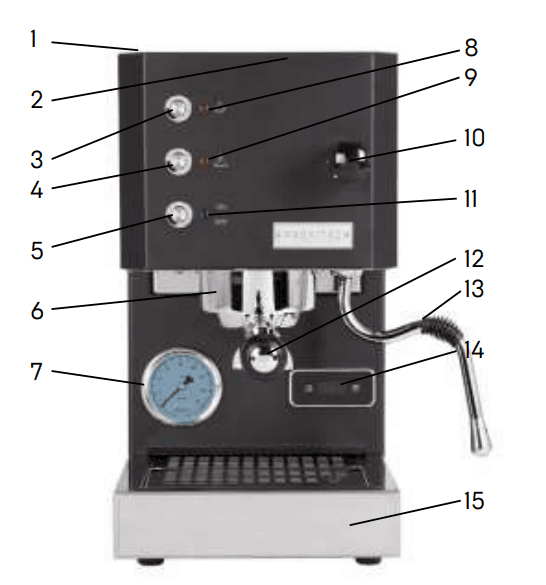

MACHINE DESCRIPTION

Machine parts

- Water tank lid, underneath water tank with a water filter adapter for holding a water filter cartridge

- Cup tray

- Coffee button

- Steam button

- ON/OFF switch

- Brew group

- Pump pressure gauge

- Orange control lamp for coffee

- Orange control lamp for heating

- Steam valve

- Green control lamp to indicate ON/OFF

- Portafilter

- Steam wand

- PID

- Drip tray

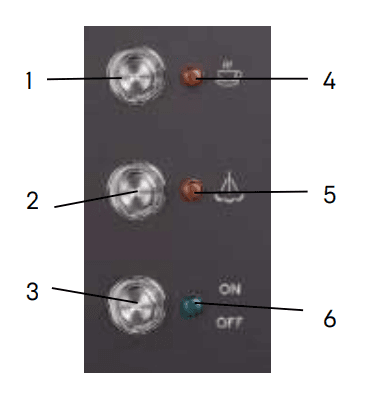

Buttons and lights

- Coffee button

- Steam button

- On/Off button

- Orange control lamp for coffee

- Orange control lamp for heating

- Green control lamp to indicate ON/OFF

Technical data

Voltages :

- EU: 230 V

- UK: 230 V

- NZ: 230 V

- AU: 230 V

- US: 115 V

- JP: 100 V

Frequency :

- EU: 50 Hz

- UK: 50 Hz

- NZ: 50 Hz

- AU: 50 Hz

- US: 60 Hz

- JP: 50/ 60 Hz

- Power: 1.300 W (EU, UK, NZ, AU), 900 W (US, JP)

- Water tank: approx. 2.8 litres

- Measurements: W 210 mm x D 338 mm x H 381 mm

- Measurements with portafilter: W 210 mm x D 410 mm x H 381 mm

- Weight: 13.0 kg

FIRST USE

Read the instruction manual carefully before operating the machine.

Before starting the machine, check if:

- The steam valve is closed.

- The switch and buttons are not activated.

- The power cord is disconnected.

- The drip tray is inserted correctly.

- The machine is placed on a water-resistant surface.

Now you can begin to operate your machine:

- Remove the water tank lid.

- Fill the water tank with fresh water, preferably low in lime. Replace the water tank lid.

- Insert the power plug into the wall socket and press the power switch. The machine is now on.

Fill Mode

When using the machine for the first time, it will be in fill mode, with “FIL” displayed on the PID. Place a small container (e. g. a. milk jug) under the brew group. Press the coffee button and the pump will begin to fill the boiler and the shot counter will begin. Wait until the shot counter has reached at least 30 and water is being dispensed from the brew group before pressing the coffee button again to stop filling the boiler. The indication “FIL” in the display should have disappeared. - The machine will now heat up. The PID display shows the boiler temperature or UP. The pump pressure gauge may deflect during the heating phase. Please note that this deflection is not relevant to the process and can be disregarded. Continue reading under chapter “6.1”.

Before preparing the first coffee, please clean the machine by extracting about 2-3 water tank fillings from the brew group.

Important!

The PID control assists the machine in keeping a constant boiler temperature. This means that the machine constantly regulates the temperature, and the small dot in the PID display flashes for one heating interval at a time. The boiler temperature is indicated on the PID display. Make sure that there is always enough water in the water tank during operation. If there is no water in the tank, the machine draws air, and a loud pumping noise can be heard. If the pump does not draw water after filling, switch off the machine and let it cool down before switching it on again.

USE OF THE MACHINE

Preparation of the machine

The switched off machine is to be placed into operation as follows:

- Make sure that there is sufficient water in the water tank. Refill water if necessary.

- Turn on the machine. If the boiler temperature is below 40°C when the machine is switched on, the display will show “UP” and the machine will start in Fast Heat Up mode.

- Make sure the portafilter is clamped into the brew group.

- The machine is heated up as soon as the desired preset temperature appears on the PID display or the display shows FLU. The heating period depends on the ambient and water temperature and is approx. 6:30 minutes in machines with 230 V and 8:30 minutes in machines with 120 V.

- While ‘FLU’ is shown on the display, the user should perform a flush until ‘rdY/Go’ is shown on the display. To do this, keep the portafilter clamped and place a tall cup under the portafilter spout. The duration for this depends on the voltage, 20 seconds at 230 V and 10 seconds at 120 V.

- When the message ‘rdY/Go’ appears, the machine is ready to brew the first cup of coffee.

- If the user does not perform a flush within the one-minute period (step 4), the display will show the message ‘FLU’ alternating with the current temperature. In this case, the flush should be started and stopped based on visual characteristics.

- If the user does not perform a flush, the boiler temperature will cool down to the desired brewing temperature after a short time.

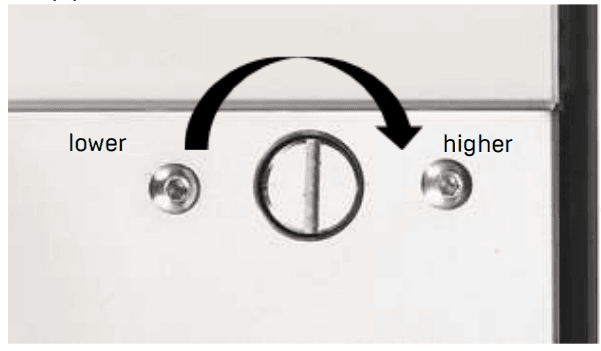

Manual adjustment of the brewing pressure

You can individually adjust and change the brewing pressure by turning the adjusting screw, choosing a

value between approx. 8.5 and 12 bar. To adjust the brewing pressure, proceed as follows:

- Remove the cup warming tray, and release some water out of the brew group by pressing the coffee

button. - Place the portafilter with the blind filter into the brew group.

- Push the coffee button and read the pump pressure gauge.

- Choose the desired brewing pressure by turning the adjusting screw with a flat screwdriver or similar.

- You can reduce the brewing pressure by turning the screw anti-clockwise and increase it by turning it clockwise.

- Read the pump pressure gauge to confirm the desired brewing pressure.

- Press the coffee button to stop the machine.

- Now the machine is ready for use again.

Pump pressure

PID temperature control

With the PID you can control the actual temperature of the coffee. This means you can extract your espresso at different temperatures. The PID display shows the current temperature. The device has a Fast Heat Up program. When activated “UP” will be displayed This always works when the boiler temperature drops below 40°C.

Temperature display (here 93°C).

By default the temperature for espresso/coffee preparation is displayed. As soon as you switch the machine to steam generation, you will see the temperature rise, and the display alternating between showing the temperature and “St” for Steam. During the extraction of espresso or coffee, the display will show the extraction time in seconds.

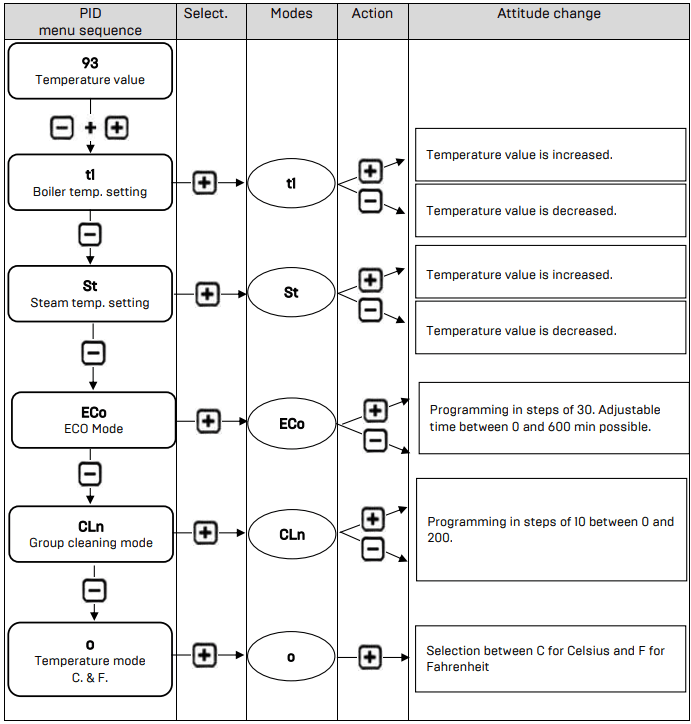

The PID menu

When you have entered the desired value, wait a moment, it will automatically exit the menu.

PID programming

The various programming options for the PID control are explained below.

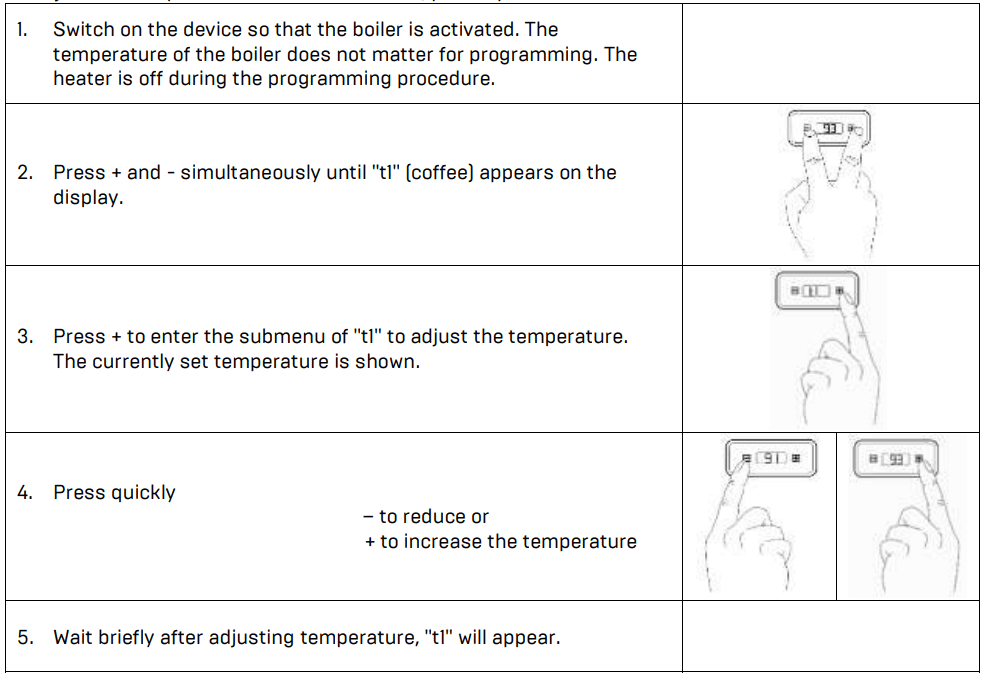

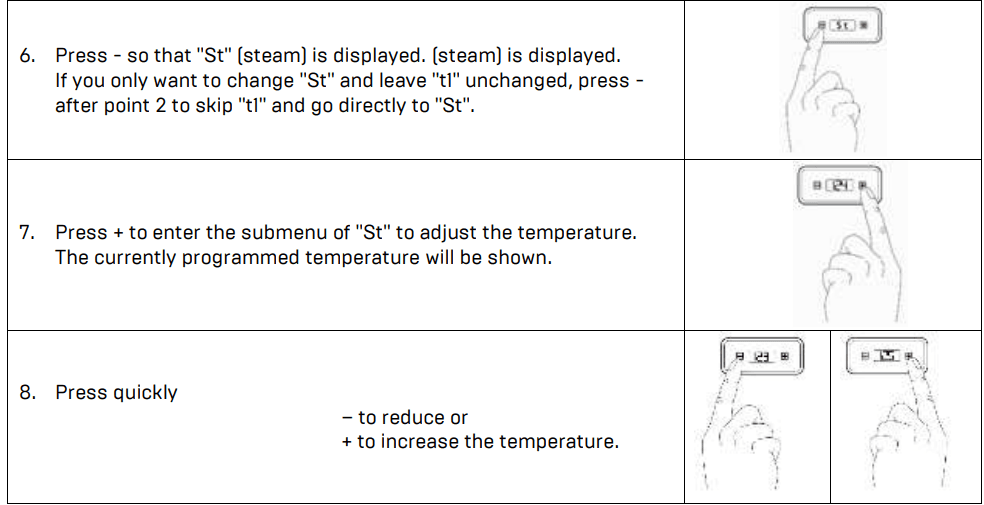

Programming the temperature setting

During operation, the actual temperature of the boiler is displayed. The factory default is programmed to

93°C for coffee and 130°C for steam. Designation: t1 = coffee, St = steam. To adjust the temperature of the coffee boiler, please proceed as follows:

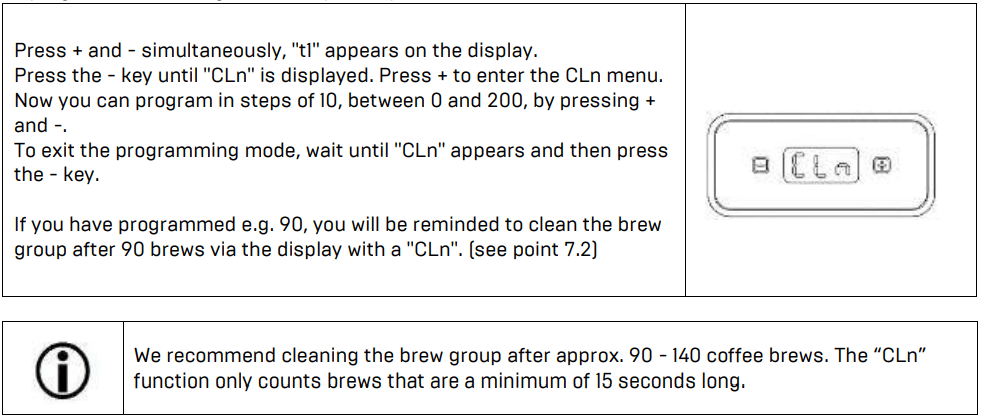

Programming the “CLn” group cleaning mode

With the GO, you can program a reminder for the next brew group cleaning via the PID display. The default setting for the machine is set to 0, so no reminder is programmed yet. To program the cleaning reminder, please proceed as follows:

Programming the ECO mode

The ECO mode allows you to set an automatic switch-off after the machine has not been used for a set

time. By default, this value is set to 90 minutes. This activates a countdown after the last brewing process, which will switch the machine off after 90 minutes have elapsed. This countdown runs automatically in the background and is not visible. After the machine has been switched off by the countdown, it can be activated by pressing the coffee dispensing switch again or by briefly switching the machine off and on again. To program the ECO mode, proceed as follows:

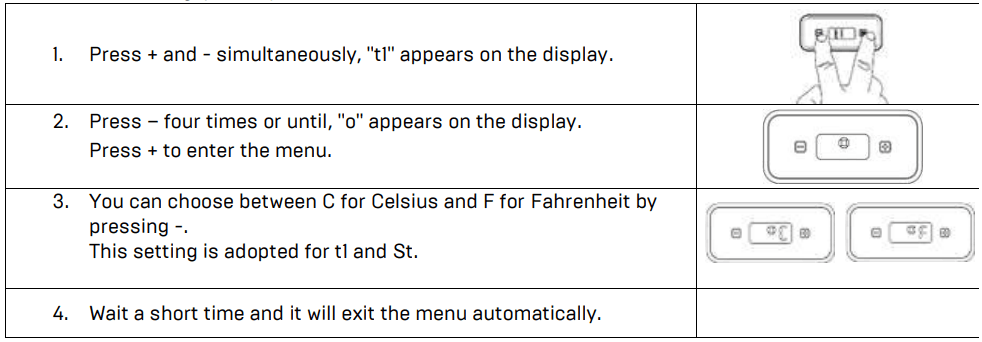

Programming the temperature measuring unit “o“

Via the PID display, you can set whether the temperature is displayed in °C or in °F. To make this setting, please proceed as follows:

Switch off the PID display

To switch off the PID press and hold the + key until the display turns off. A dot appears on the display, showing you that the machine is switched on. To switch on the display press the + key again.

Preparing coffee

Use the portafilter with the appropriate filter (1 cup) to prepare 1 cup and the large filter (2 cups) to prepare two cups. Make sure that the filter is firmly implanted into the portafilter. Fill the filter with ground coffee of the appropriate grind for espresso. (The marking inside the filter basket will help you fill it with the correct amount of coffee). Compress the ground coffee with a tamper. A tamping pressure of about 20 kg is recommended. This will compact the ground coffee evenly. Clap the portafilter firmly into the brew group. Place the cup under the spouts of the portafilter (to prepare two cups, place one cup under each spout). After pressing the coffee button, coffee brewing begins. Generally, the brewing time should be about 23 to 25 seconds. The volume for a single espresso is approximately 25 to 30 ml. The pump pressure gauge indicates approximately 8.5 – 12 bar. When the cup is filled, press the coffee button on the control panel again. The remaining pressure/water is drained into the drip tray via the outlet connection behind the drip tray.

CLEANING AND MAINTENANCE

Regular and accurate care is very important for the performance, the longevity and the operational safety of your machine.

General cleaning

Daily cleaning:

Portafilter, filters, water tank and drip tray require daily cleaning. Clean with water and/or with a food safe detergent.Clean the shower screen and the group gasket in the lower part of the brew group and remove visible dirt without dissasembling the parts using a hard cleaning brush.

Cleaning as necessary:

Clean the steam valve after every use. Clean the body when the machine is switched off and cold.

Brew group cleaning and degreasing

The brew group is easily cleaned with special brew group cleaning agents. The cleaning is carried out

using the blind filter included in the delivery. Follow the instructions as noted below:

- Heat up the machine.

- Place the blind filter into the portafilter.

- Put approx. 3 – 5g of the group cleaning powder into the blind filter.

- Clamp the portafilter into the group head.

- Press the coffee button. The blind filter will fill with water.

- Press the coffee button in intervals of approximately. 20 seconds.

- Repeat point 6 several times until the water released by the outlet connection is clear again.

- Remove the portafilter again, rinse it with fresh water and place it back into the brew group.

- Press the coffee button. The portafilter is filled with water again. Repeat this several times.

- Remove the portafilter and place a filter into the portafilter. Now the brew group is ready for use again.

Maintenance

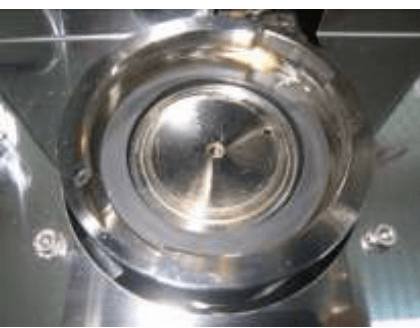

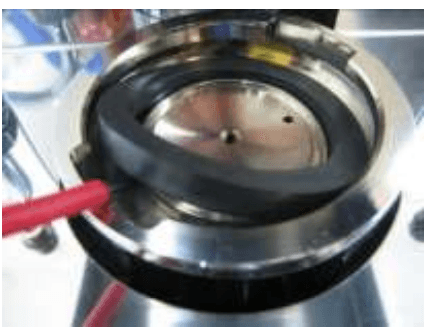

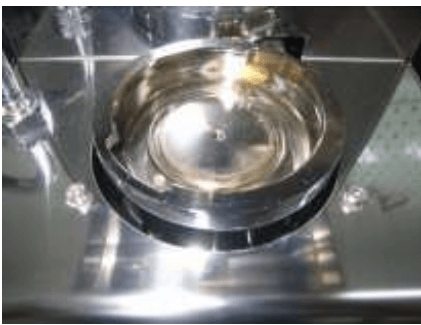

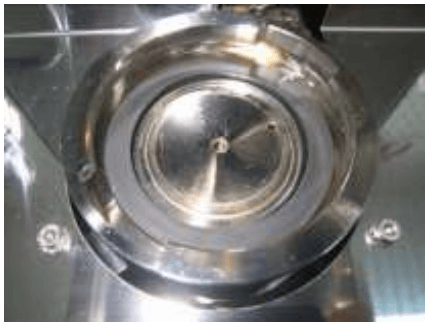

Replacing the group gasket and the shower screen

- Switch off the machine, disconnect the power cord and make sure that the machine is cooled down to room temperature.

- It is recommended to remove all the removable parts (cup warming tray, water tank lid, water tank, drip tray), then turn the machine over.

- Loosen the countersunk screw in the middle of the brew group and the shower plate with an Allen key (3mm).

- The shower screen and the shower holder (brass) can be removed easily.

- Under the shower holder is a thin ring, the gasket of the shower plate.

- The group gasket can only be removed by inserting a thin screwdriver between the shower holder and the group gasket. Pry out the group gasket (the old group gasket will be damaged/destroyed).

- Clean the groove completely before installing the new group gasket.

- When inserting the group gasket, ensure that the bevelled side is facing upwards so that it is no longer visible.

- Press the group gasket gradually into the cleaned groove.

- Then screw in the shower plate and the shower holder.

- To ensure that the group gasket is inserted properly, carefully clamp a portafilter without a filter into the brew group.

- The brew group is ready for use again.

Follow the steps as indicated below:

- Brew group at the beginning.

- Remove the countersunk screw in the middle of the brewing unit.

- Remove the shower screen and the shower plate.

- Remove the thin gasket of the shower tray.

- Now the group gasket can be removed.

- Remove the group gasket with a screwdriver.

- Clean the groove before inserting the new group gasket.

- Insert the new group gasket with the rounded side facing upwards.

- Re-insert the gasket and the shower screen as seen in pict.4 and tighten them with the countersunk screw.

The steam nozzle is blocked

Clean the holes of the steam nozzle carefully with a needle or similar. For this purpose, the steam nozzle may also be unscrewed. Replace the steam/ hot water nozzle.

TRANSPORT AND WAREHOUSING

Packing

The GO is delivered in a special carton and protected by a plastic cover and foam.

Caution!

Keep packing out of reach of children!

Important!

Keep packing and packing material for possible transport! Do not discard!

Transport

- Transport the machine in an upright position, on a pallet if possible.

- Do not tilt or turn the machine over.

- Do not stack more than three units on top of each other.

- Do not place other heavy items on the packing.

Warehousing:

- Keep the machine packed in a dry place.

- Do not stack more than three units on top of each other.

- Do not place other heavy items on the packing.

DISPOSAL

This product complies with EU Directive 2012/19/EU and is registered according to WEEE (Waste Electrical and Electronic Equipment

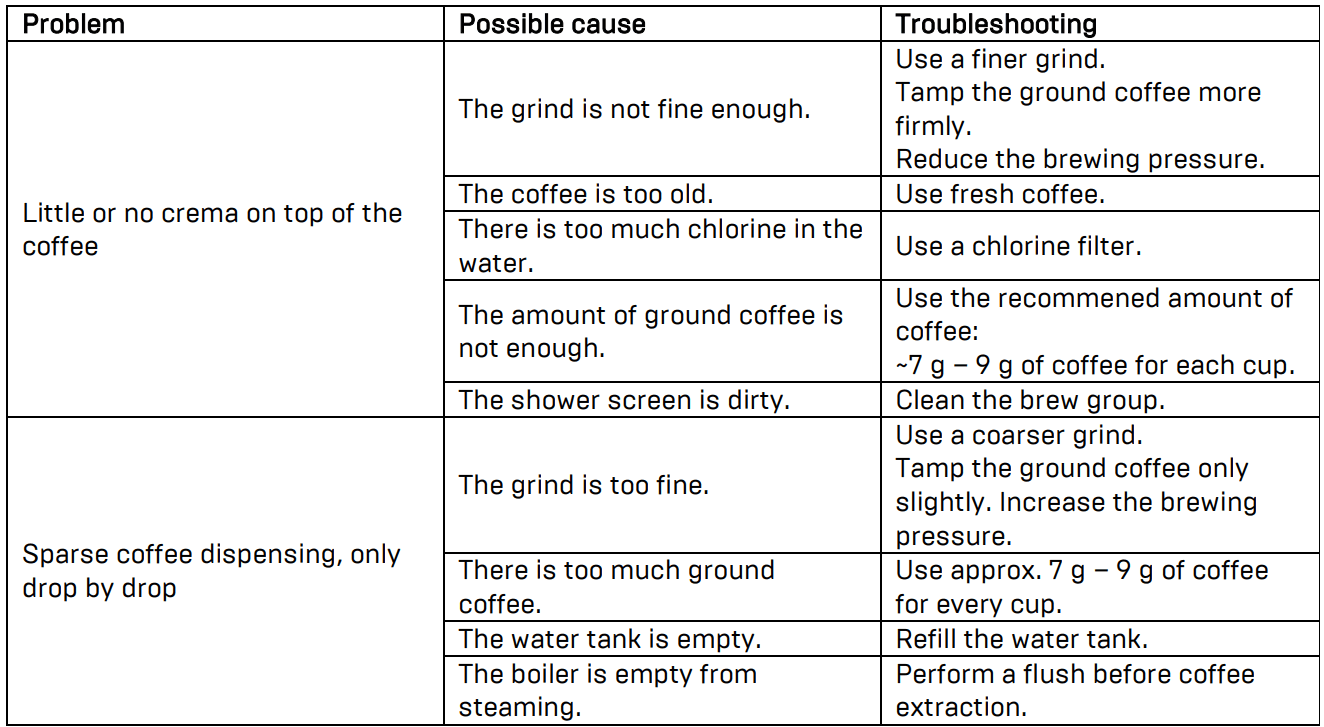

TROUBLESHOOTING

If the machine is not to be used for a long period, it is recommended to;

If the machine is not to be used for a long period, it is recommended to;

- clean the group. After this, please do not clamp the portafilter back into the group.

- dispense approx. 100 ml of water through the brew group and approx. 100 ml through the steam tube.

How to froth milk like a “barista”.

- It is recommended to use cold, fresh milk with a fat content of 3.5 % or lower. If you prefer, use

homogenized milk. - Use a metal frothing container with a minimum volume of 350 ml. The container should not be too

wide. A narrow and high container is recommended. - Open the steam valve for approximately. 5 seconds to release the condensation water and to create dry steam.

- Fill 1/3 of the container with milk and place it under the steam nozzle. The nozzle should be immersed in the middle of the frothing container underneath the surface.

- Slowly open the steam valve to begin steaming the milk.

- Keep the frothing container still.

- After a few seconds, you will notice a light suction in the milk jug as frothing begins. Move the milk jug downwards as the milk level increases. The steam nozzle must be kept under the surface of the

frothed milk. - Attention: When the desired amount of milk froth has been reached, immerse the entire steam nozzle in the frothing container for a short time and close the steam valve.

For more manuals by Profitec, visit ManualsLibraryy

Profitec GO Espresso Machine-FAQs

What are the key features of the Profitec GO?

Single-boiler design with a vibratory pump

Built-in PID temperature control for precise brewing

Shot timer for consistent extraction

Saturated group head for even heat distribution

Compact size with a 3L internal water reservoir

Where is the Profitec GO made?

Handmade in Germany and Italy, ensuring high-quality craftsmanship.

When was the Profitec GO released?

It launched in early 2023 and quickly became popular for its performance and affordability.

How long does the Profitec GO take to heat up?

Approximately 6-7 minutes thanks to its Fast Heat-Up (FLU) mode.

Does the Profitec GO have a PID?

Yes, it features PID temperature control, allowing precise adjustments for optimal extraction.

Does it have pre-infusion?

No, the Profitec GO does not support pre-infusion.

What is the steam temperature?

The boiler reaches 270°F (132°C) for powerful milk frothing.

Is the Profitec GO good for milk drinks?

Yes, but since it’s a single-boiler machine, you must switch between brewing and steaming.

How often should I clean the Profitec GO?

Every 150 shots or every two months

Use a coffee oil remover for the brew group

Soak the portafilter, shower screen, and dispersion plate in hot water with cleaner

Can I backflush the Profitec GO?

Yes, it has a 3-way solenoid valve, allowing backflushing with a blind basket.