Riccar 8500 Sewing Machine

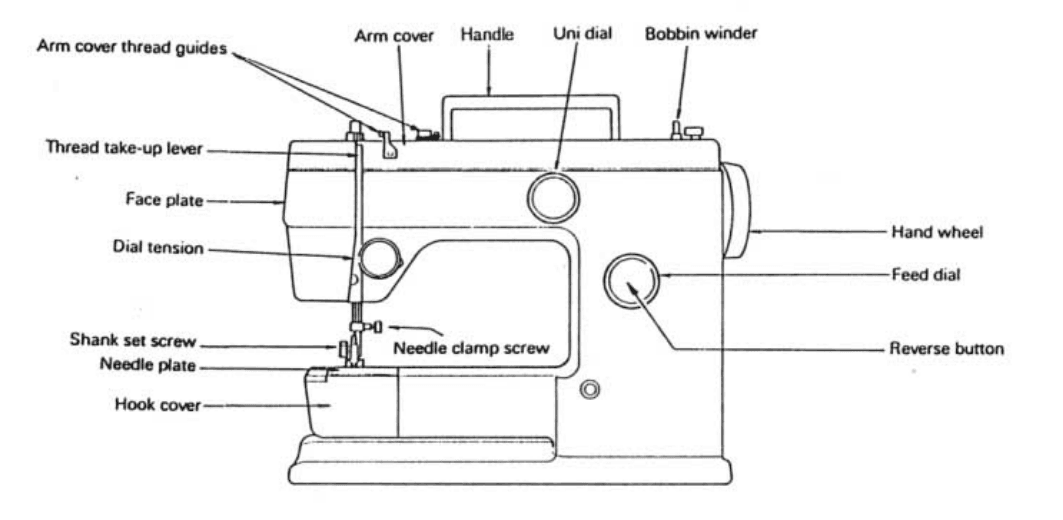

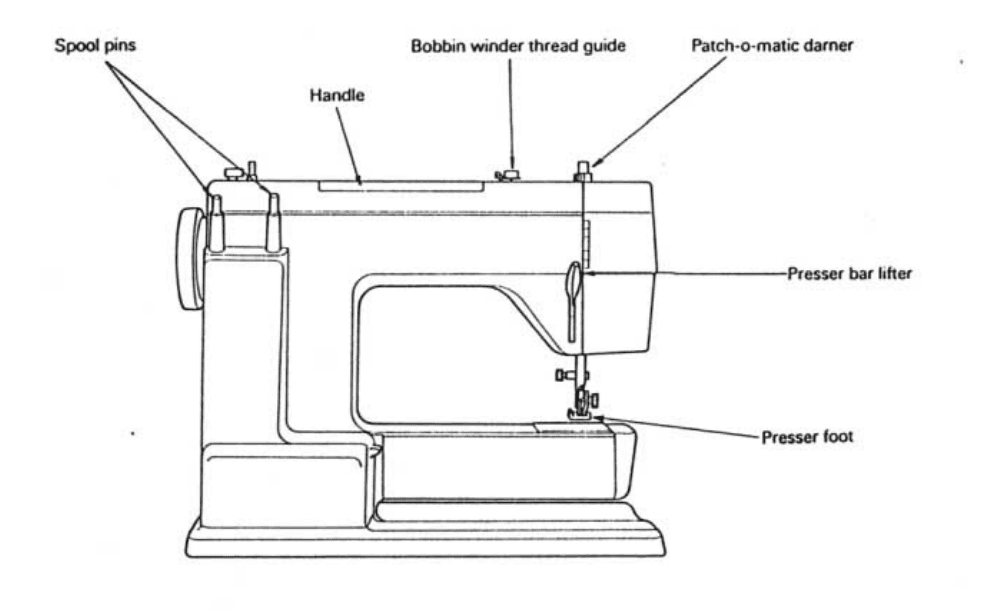

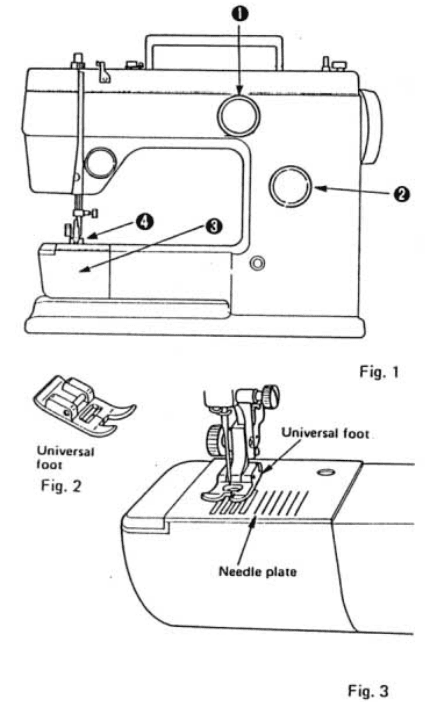

NAME OF MAIN PARTS

FITTING THE SNAP·ON THE SEWING TABLE

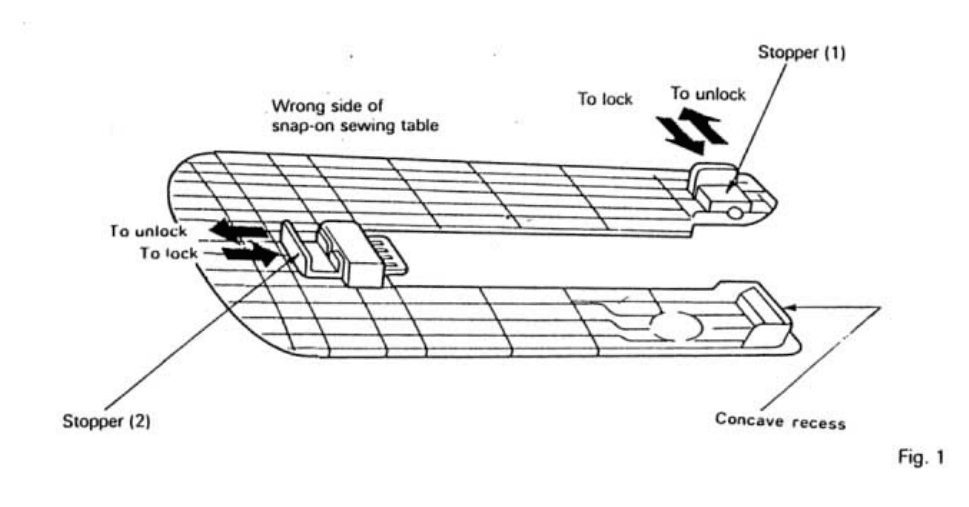

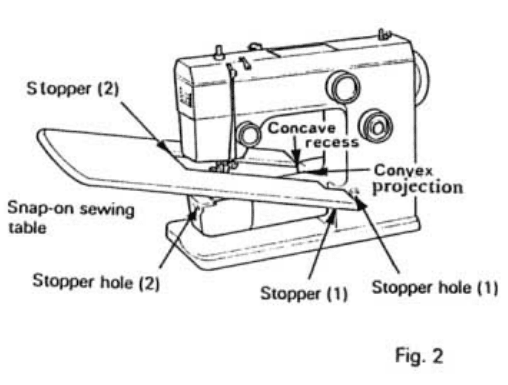

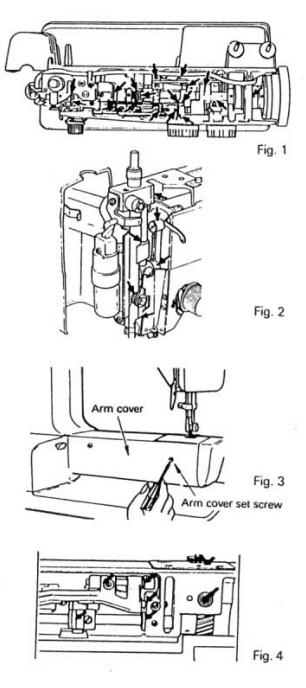

Hold the snap-on sewing table on the slam as shown and set the concave recess to the convex projection of the machine pulling the stopper (I). (Figs. 1 & 2)b. Align the stopper (1) to the stopper hole (1) and release the finger to lock. Lower the snap-on sewing table down to a horizontal position pulling the stopper (2) toward the left. Align the stopper (2) to the stopper hole (2) and release the finger. (Figs. 1 & 3). When you change the bobbin. pull the stopper (2) only toward the left and push the left side: of the snap-on sewing table upward. You do not have to remove it completely.

Hold the snap-on sewing table on the slam as shown and set the concave recess to the convex projection of the machine pulling the stopper (I). (Figs. 1 & 2)b. Align the stopper (1) to the stopper hole (1) and release the finger to lock. Lower the snap-on sewing table down to a horizontal position pulling the stopper (2) toward the left. Align the stopper (2) to the stopper hole (2) and release the finger. (Figs. 1 & 3). When you change the bobbin. pull the stopper (2) only toward the left and push the left side: of the snap-on sewing table upward. You do not have to remove it completely.

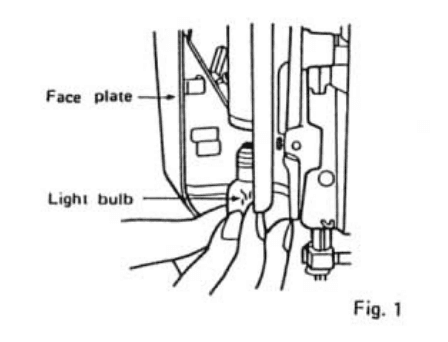

TURNING THE LIGHT ON AND OFF

The sewing light is built into the face plate and is turned on and off using the push switch located on the right side of the vertical arm of the machine. When replacing the light bulb, first be sure to unplug your sewing machine. Swing out the face plate, then the light bulb is easily accessible and can be removed just as an ordinary light bulb (Fig. 1). Always ensure that the bulb is screwed in tightly.

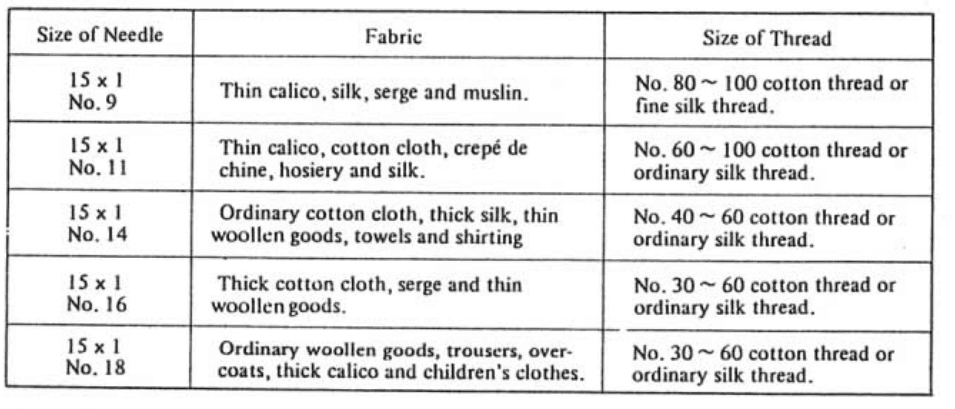

CORRECT NEEDLE AND THREAD FOR FABRICS

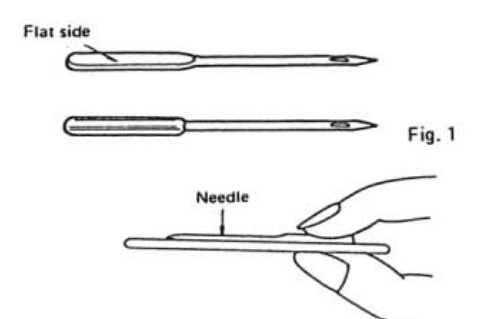

INSERTING THE NEEDLE

It is very important to select the correct needle and thread to get a good stitch. Select the proper needle according to 10 the type or materials to be sewn, referring to the above chart. A bent needle will not produce good work. Check the needle by placing i1s nat side against a flat plane. If the needle is bcn1 or a sharp point has bcc:n damaged, a faulty needle: can cause

- thread breakage

- excessive: noise while the machine is in motion

- damage to the needle plate

- skipped stitching, etc. (Figs. 1 & 2)

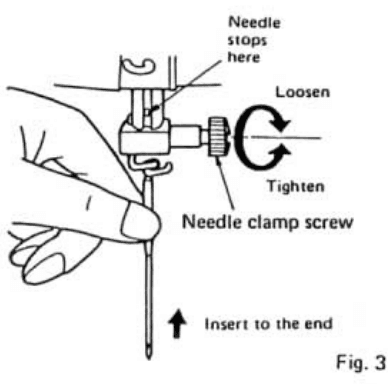

Raise the needle bar to its highest point by turning the hand wheel toward you. Loosen the needle clamp screw and insert the needle upwards into the clamp as far as it will go, facing the flat side of the needle: lo the rear. Tighten the needle clamp screw with a screwdriver. (Fig. 3) After inserting the needle, check to see that it is correctly fitted. Turning the hand wheel toward you slowly, make sure that the needle is aligned with the center of the hole of the needle plate. During this procedure, the Uni dial must be set at “O”.

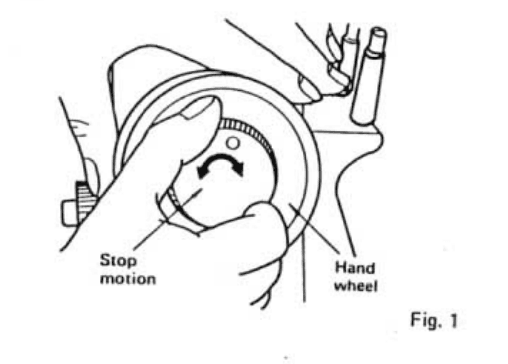

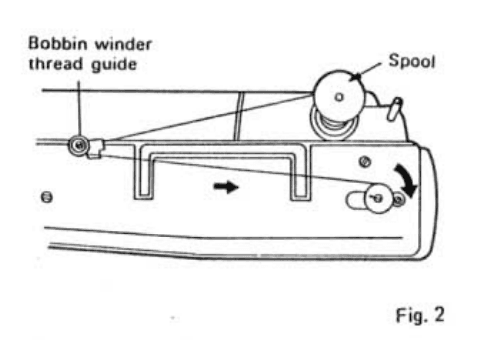

WINDING THE BOBBIN

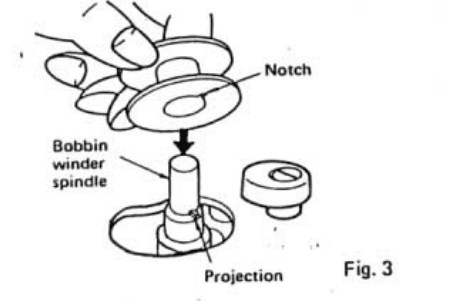

To wind the bobbin, first, turn the stop motion large screw, counterclockwise to disconnect the sewing machines. (Fig. 1). Place a spool on the spool pin and guide thread as illustrated. (Fig. 2). Wind the thread around the bobbin several times and insert the bobbin on the bobbin winder spindle. (Fig. 3). Push the bobbin winder spindle in 1he direction of the arrow then turn the hand wheel slightly toward you while holding the end of the thread. (Fig. 3)

Place the foot control so that your fool rests on it comfortably. S1an the machine winding 1he bobbin

by gently pressing down 1hc foo1 con1rol. The more you press the fool control down, the faster the

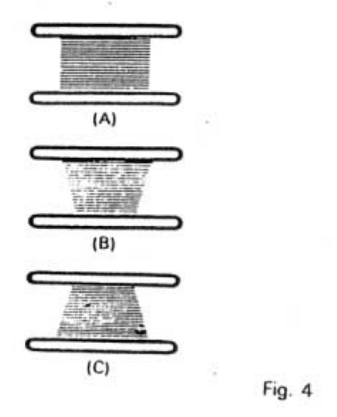

machine runs. When the bobbin is full, the bobbin winder will be automatically released. Stop 1he machine and take it off after pushing the spindle back to its original position. Wind thread evenly as ”A” and avoid winding as “B” or hC”. After the bobbin has been wound, turn the stop motion a large screw clockwise to reconnect the sewing mechanism.

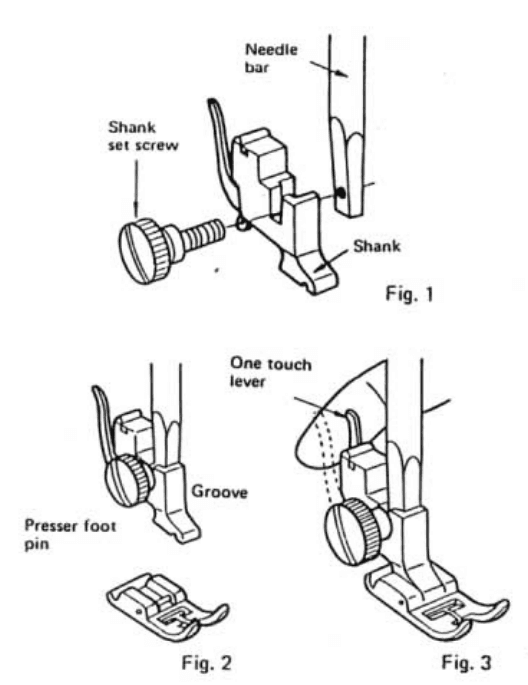

CHANGING THE PRESSER FOOT

To attach the shank, raise the needle bar 10 to its highest point by turning the hand wheel toward you anti attach the shank to the presser bar by means of the shank set screw. (Fig. 1) Place a presser foot exactly under the shank. Lower the presser bar by means of the presser bar lifter, checking to see that the groove of the shank fits the presser footpin. Then pull the one-touch lever. (Fig. 2). To take off the. presser fool, pull the one-touch lever after having raised the needle bar. (Fig. 3)

STRAIGHT STITCH SEWING

For normal straight-stitch sewing, set the machine as follows.

- Uni dial …………………………………… 0

- Feed dial ………………………………… I ~ 5

- Drop feed …………………………….. .—-

- Presser foot …………………………… Universal foot

For elastic straight stitch sewing, set the machine as follows. Please refer to SEWING ELASTIC MATERIAL on page 23.

- Unidial ……………………………….. .—-

- Feed dial ………………………………… J ~ S

- Drop feed …………………………….. .—–

- Presser foot ……………………….. Universal foot

In normal sewing. The universal foot is adequate. (Fig.2) In straight sewing, be sure that the needle is

aligned with the center of the needle hole of the presser foot and the needle plate by turning the hand wheel toward you. (Fig. 3)

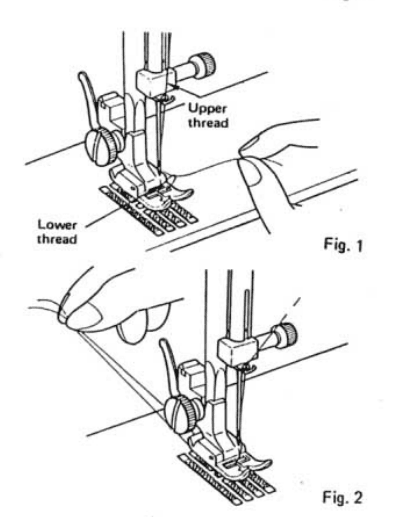

START SEWING

Hold the upper thread lightly with your left hand. Turn the hand wheel toward you with your right hand until the needle enters into the needle hole catch the lower thread and come up again bringing it up through the needle hole. (Fig. 1) Pick up the ends of both threads together and draw them through under the presser foot to the back of the machine. ( Fig. 2)

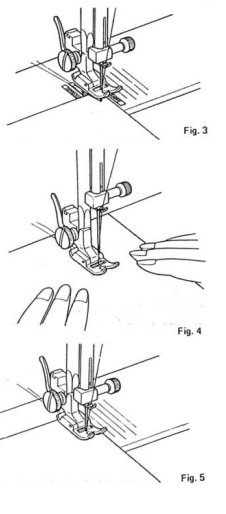

Place the material under the presser foot and position the needle in the material. Lower the presser fool using the presser bar lifter and start sewing. (Fig. 3 & 4). It is not necessary to pull or push the fabric by

Place the material under the presser foot and position the needle in the material. Lower the presser fool using the presser bar lifter and start sewing. (Fig. 3 & 4). It is not necessary to pull or push the fabric by

hand, just guilt it slightly in the desired direction. (Fig. 5) Place the foot control so that the foot rests on it comfortably. Start the machine by gently pressing down the foot control. The more you press the foot control button, the faster the machine runs.

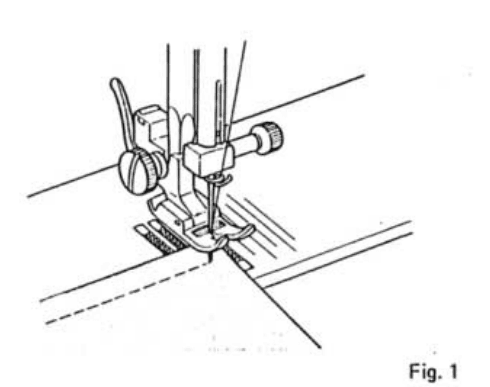

CHANGING SEWING DIRECTION

To change the sewing direction, raise the presser foot leaving the needle in the material, and change the direction of the material. (Fig. 1)

After making the channel lower the presser foot and resume sewing. (Fig. 2) For reverse sewing push the reverse button. Reverse sewing will continue as long as the button is pushed. When the button is relesed the machine will return to forward sewing. (Figs. 1 & 2)

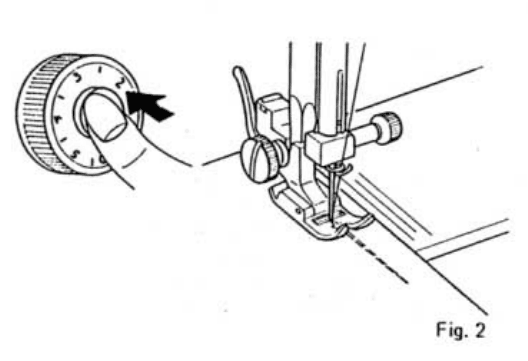

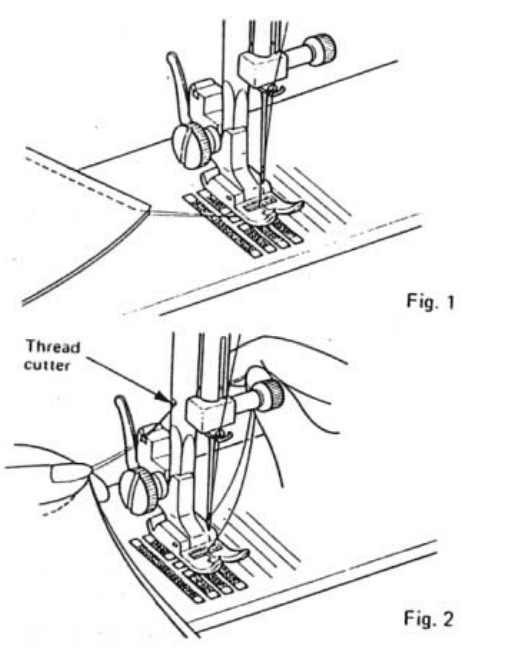

REMOVING MATERIAL

Stop the machine with the needle bar at the highest point. Raise the presser foot through the presser bar lifter and remove the material by pulling it diagonally to the left. (Fig. 1) Be sure to remove the material diagonally to the left and cut the thread with the thread culler. leaving about 12 cm (5″) frt:e at the ends. This makes it easier to resume sewing. (Fig. 2)

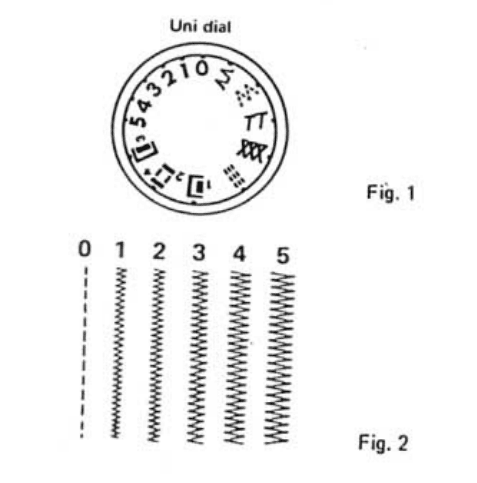

ADJUSTING ZIGZAG WIDTH

The width of the zigzag stitch can be adjusted by means of the uni dial. Numerals from O to 5 on

the uni dial indicate the width of zigzag sewing. (Fig. 1) The lower the numeral, the narrower the stitch

width. The zigzag stitches illustrated here show the width obtained with each uni dial selling from 0 to 5. (Fig. 2)

MANUAL ZIGZAG SEWING

For sewing zigzag stitches, set the machine as indicated.

- Uni dial …… – …………………………. Desired zigzag width

- Feed dial …………, __ 0.5 ~ 1

- Drop feed …………………………….. —–

- Presser foot ……………. __ Universal foot

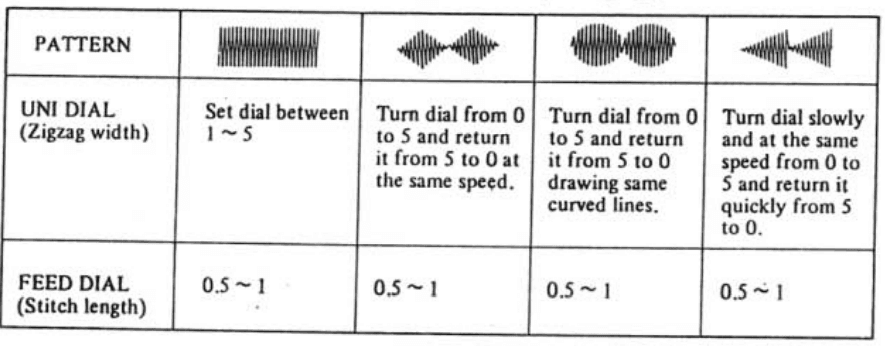

Varied zigzag patterns can be obtained by alternately changing positions of the uni dial anti-feed dial.

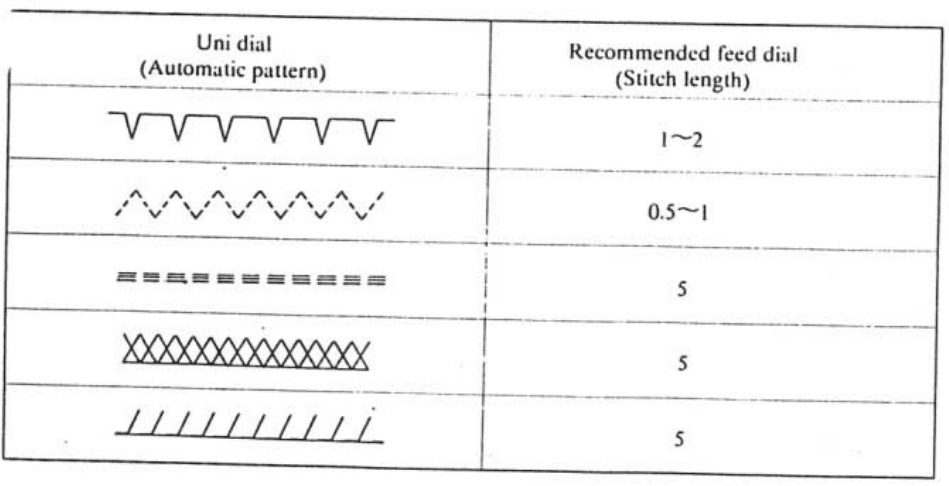

AUTOMATIC ZIGZAG SEWING

For sewing automatic patterns, set the machine as indicated.

- Uni dial …………………………………… Desired pattern

- Feed dial ………………………………. As recommended

- Drop feed ……………………………. —–

- Presser foot ………………………….. Universal foot or as recommended

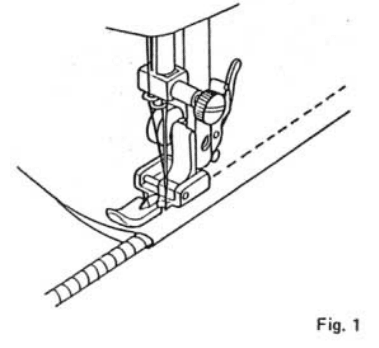

ATTACHING CORD (1)

For attaching the cord as illustrated, set the machine as follows.

- Uni dial…………0

- Feeddial ………. 1∼3

- Dropfeed………. —

- Presser foot ……………….. Zipper foot

The zipper foot can also be used to sew close to a suitable cord as illustrated. (Fig. 1)

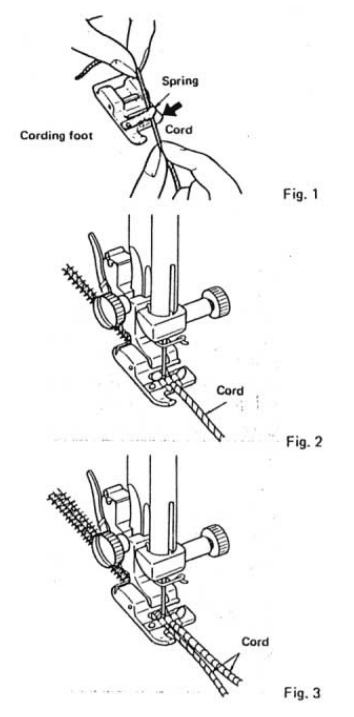

ATTACHING CORD (2)

For cording, proceed as follows.

- Uni dial ………. Width of cord

- Feed dial…………. 1 ~ 3

- Drop feed………..—-

- Presser f0ot………. Cording foot

Pass the cord or string through the hole of the cording foot. Adjust the zigzag width according to the width of the cord. (Fig. 1) Start sewing, taking care that stitches appear on either side of the cord (Fig. 2 & 3)

APPLIQUE

Applique is one of the most interesting and fancy applications of your zigzag sewing machine. You will add to effectiveness by using contrasting fabrics.

For applique, set the machine as follows.

- Uni dial………..0~ 3

- Feeddail…………0.5∼3

- Dropfeed……….——

- Presser’s foot ……………. Universal foot

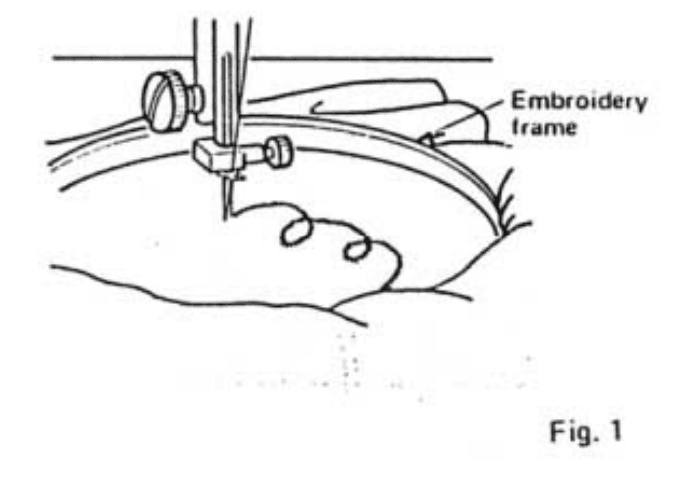

EMBROIDERY

To make embroidery set the machine as follows.

- Un dail……. 0∼5

- Feed dial………..////

- Dropfeed………….

- Presser………no foot needed

Use an embroidery frame with a diameter between 4 to 5 inches and needle No. 11 together with embroidery thread. Stretch the fabric tightly over the frame and secure it tight by tightening the screw.

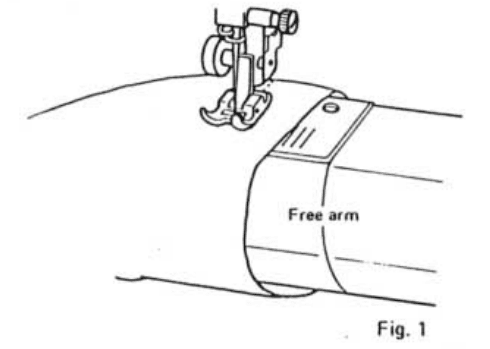

FREE-ARM SEWING

Take off the snap-on sewing table and use the free arm for sewing sleeves, trousers, etc.

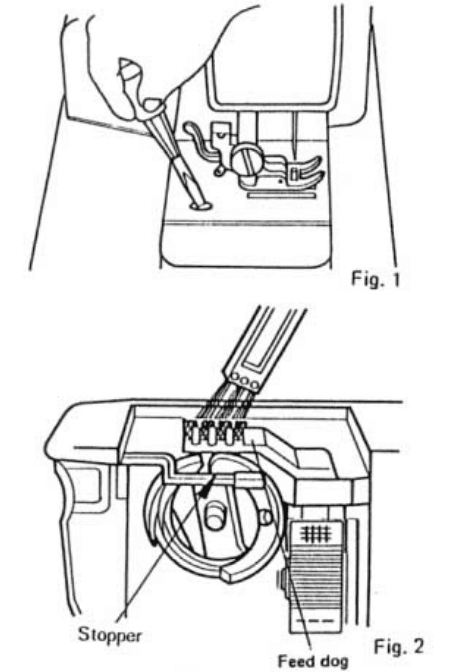

CLEANING THE FEED DOG

Pieces of thread and/or dust accumulating between the needle plate and the feed dog will cause trouble. Always keep the machine clean. Remove the needle, presser foot, and needle plate with a screwdriver. (Fig. 1) After removing the parts, clean all necessary parts with a brush while turning the hand wheel toward you. Be sure that cleaning is thorough.

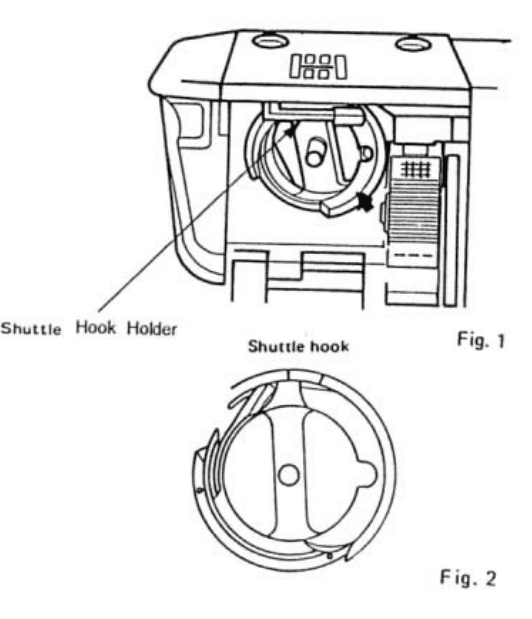

CLEANING SHUTTLE RACE AND 5-HOOK

Raise the needle bar to its highest point by turning the hand wheel toward you,

- Open the shutter hook cover.

- Take out the bobbin case.

Clean dust and gummed oil off the cach part with an oiled cloth. When finished cleaning and oiling, reassemble reversing the above procedure.

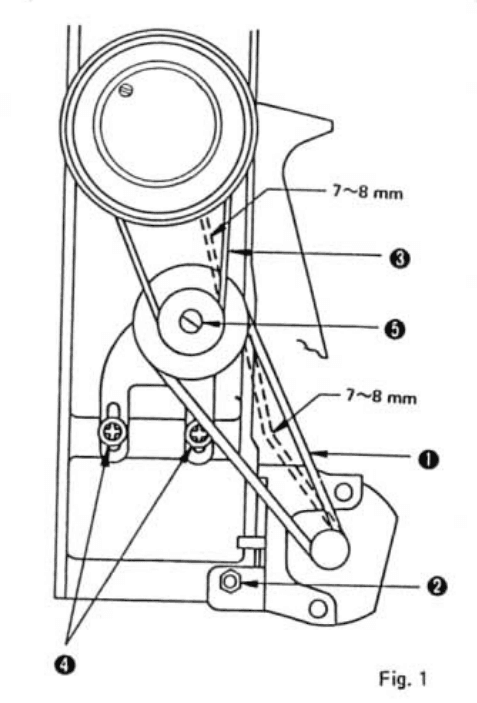

ADJUSTMENT OF MOTOR DRIVE BELT

To adjust the tension of the motor drive belt, and/or the timing belt, loosen the set screw holding the mounting bracket and/or idle pulley bracket to the machine, then move the bracket up to loosen, or

down to tighten the belt as required. Adjustment of the tension of the timing belt is to be made first.

Please do not have the belt too tight as the motor will not operate effectively. When correctly adjusted,

tighten the set screw on the bracket. The machine is so assembled that alignment adjustment of the belt to be out of alignment is not necessary. Adjust the belt so as to achieve 7-8 mm flexibility as shown in Fig. 1.

- Motor drive belt

- Motor bracket holding set screw

- Timing belt

- Idle pulley bracket holding set screw

- idle pulley

OILING ARM AND BED

Oil the machine at least once a month to keep it in good condition, even if it is not used for a long period. While oiling, turn the hand wheel slowly toward you so that oil will cover every part.

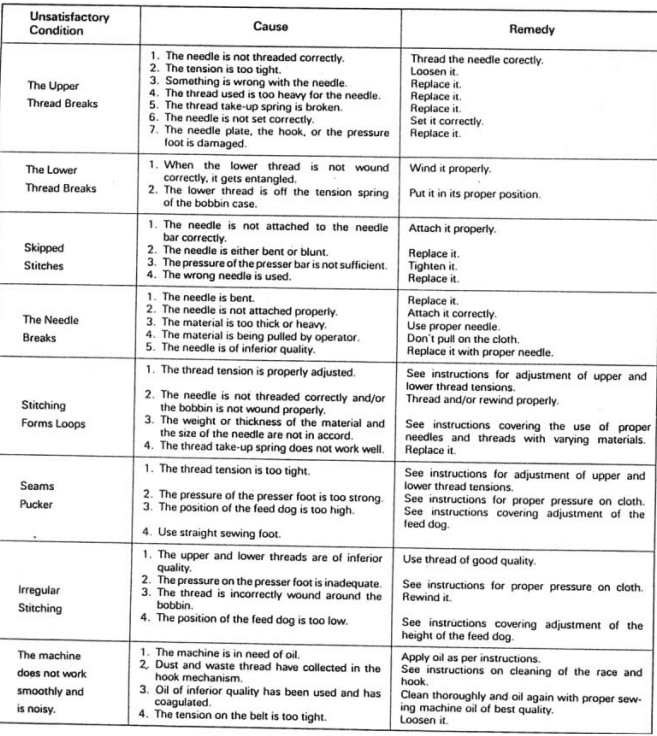

TROUBLESHOOTING GUIDE

For more manuals by Riccar, visit ManualsLibraryy

Riccar 8500 Sewing Machine-FAQs

Who manufactured Riccar sewing machines?

Riccar was founded on September 16, 1939, initially under the name Nippon Shokusan Kogyo and later Rikagaku Kogyo. The company started producing sewing machines in 1948 in Tachikawa, Tokyo.

Are Riccar sewing machines still available?

No, Riccar no longer sells sewing machines. However, replacement parts may still be available through reputable sewing machine repair shops.

Who invented the sewing machine?

The first practical sewing machine was invented by Elias Howe in 1846.

What is a well-known German sewing machine brand?

PFAFF is a renowned German sewing machine brand, now owned by SGSB Co. Ltd.

What is a spool pin?

A spool pin is a small rod on a sewing machine that holds the spool of thread in place while sewing. It is typically made of metal or plastic and fits various spool sizes.

How can I identify my Riccar sewing machine model?

The model and serial number can be found on a silver label on the machine, often displaying the Riccar logo or ETL/UL logo.

Where are Riccar machines made?

Riccar sewing machines were originally manufactured in Japan, but their vacuum cleaners are primarily made in the USA with globally sourced parts.

Why is it called a “bobbin”?

The word “bobbin” comes from the French word “bobine”, meaning a small instrument used in sewing, which is believed to reference the sound it makes while unspooling.