Scantronic 9800 Security Alarm System

Introduction

The 9800 Alarm Control Panel comprises a control unit in a shielded case, and up to four separate keypads.

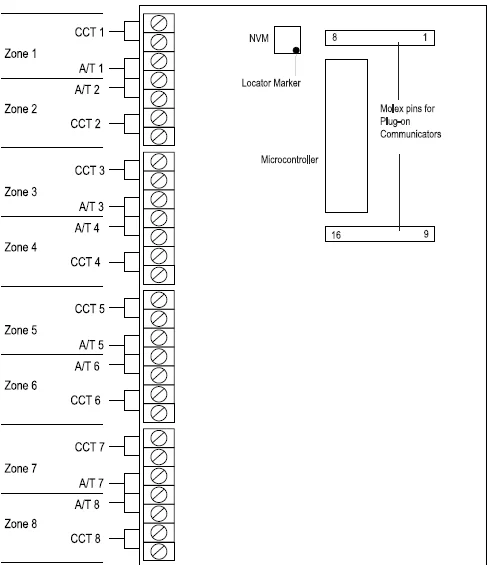

The control unit provides:

- Connections for up to eight Closed Circuit zones.

- Connections for four outputs (external sounder, strobe, and two fully programmable outputs).

- Connections for up to four 9825 Keypads.

- Pins for fitting a plug-on communication device. Any device that complies with the Scantronic plug-on footprint can be fitted.

- Internal sounder loudspeaker output with electronically generated Chime, Alarm, and Fire tones.

The programming interface is arranged as a set of two-digit numbered commands.

The system can provide for up to 4 separate users. User facilities include:

- Three different security levels (full set and two-part sets), which can be programmed by the installer.

- User programmable Duress code.

- Keyswitch setting/unsetting.

Technical Specifications

General

- Operating temperature = -10 °C to + 40 °C.

- Humidity = Up to 80% non-condensing.

- Dimensions = h x w x d 300 x 300 x 75 mm.

- Weight = 4.85 Kg (excl battery).

- Standby Battery = 12 Volt, 6.0Ah rechargeable lead-acid, Gel Type battery.

Power Supply

The total current available from the control unit is as follows:

- System output current = 800mA (Ambient Temp. 20 °C).

- Control unit PCB = 60mA quiescent, 500mA active (when driving standard external bell).

- Each 9825 Remote Keypad = 20mA quiescent, 60mA active.

- Standard 9066 SAB Module = 40mA.

- Plug-on 9056 Communicator = 40mA.

Keypad Wiring

Recommended maximum distances for the remote keypads from the control unit, using standard alarm cable, are 100 metres for the star configuration.

Outputs

OP1, OP2, Bell, Strobe = 500mA. Transistorised outputs capable of driving a relay.

9825 Keypad Addressing

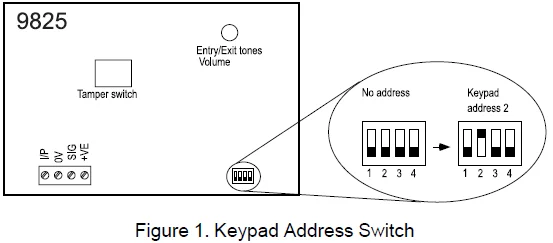

Before connecting the keypad(s) to the system, the engineer must set the address of each keypad. Each keypad in a system must have a different address number to ensure that the control unit can correctly identify them.

To set the address:

- Ensure the system is powered down.

- Open the keypad and identify the four-position DIP switch on the keypad PCB, see Figure 1 below. Note that each switch is numbered 1 to 4. The numbers correspond to the keypad address.

- Select one switch and move it to the ON position (up). Make sure all the other switches are OFF (down). The keypad now has the address given by the switch that is ON.

Adjusting Keypad Sounder Volume

You can alter the volume of the keypad sounder by adjusting the potentiometer located next to the sounder. See Figure 1. When first installing the keypad, set the potentiometer midway using a small screwdriver.

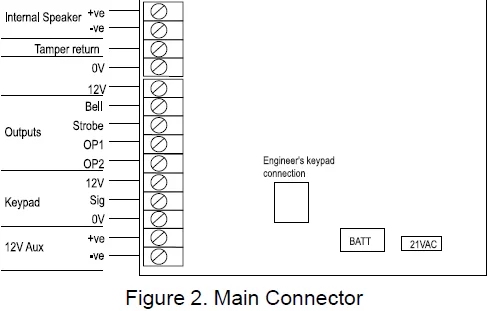

Wiring

Figure 2 shows the main connector on the control unit PCB. Subsequent sections describe how to wire keypads and closed-circuit zones.

Wiring Keypads

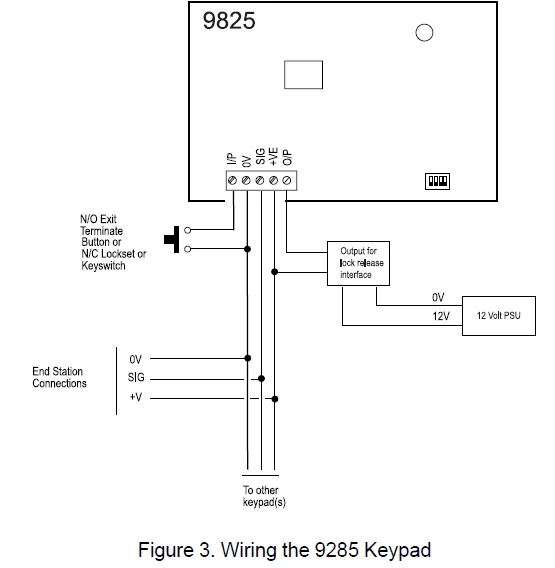

All keypads must be connected to Keypad terminals on the control unit PCB or “daisy-chained” to other keypads. Figure 3 shows the connections for each keypad using the 9285 as an example:

Note: The output for the lock release interface must be a transistorized type. A recommended type is RS Components 349-254. A SEPARATE 12 Volt DC supply is required. Contact rating is 10 A.

Caution: Do not connect other devices (for example, SAB, speakers, and so on) to the same cable as the remote keypad wiring.

Wiring Keyswitches

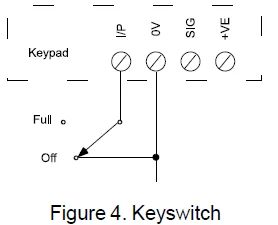

Connect a keyswitch to the I/P and 0V terminals of the nearest keypad (see Figure 4). Make sure you use a two-position, unbiased keyswitch.

Communications

The control unit can be fitted with communicators that conform to the standard Scantronic plug-on communicator footprint (for example, the 9056 and 9058 Plug-on Digital Communicators, a 960 Speech/Digital Communicator, or a Plug-on Red Care Transmitter). For communicators that do not conform to the 9076-01 and 9076-02 can be used as interfaces to the system.

Programming

Initial Power Up

When all wiring is complete, power up the system for the first time as follows:

- Ensure that the keypad(s) and detectors are securely fitted and their tamper switches closed.

- Connect the battery and then close the case.

- Switch on the mains power. Ignore any tones from the internal and keypad sounders.

- Go to a keypad and key in 1234.

- Key in 0 followed by 7890 (the default Engineer’s code). The keypad gives an intermittent tone.

- Open the end station lid. (If the lid is already open, close and open the tamper switch.)

The display shows “E” (engineer).

You are now in programming mode.

Programming Commands

When delivered from the factory, the control unit already has default program settings. To change the default programming, you must be in programming mode. Then:

- Key in the appropriate command number. The display shows the current value of the command.

- Key in digits to select the value you require. The display shows a code giving the new value.

- Press Clear to store the new value of the command.

If at any time you change your mind, repeat steps 1 to 3. The table on the following pages shows the commands and their options. ( A tick next to a command value shows that it is the factory default.)

The factory default access codes are:

- Engineer Code 7890

- Access Code User 1 1234

- Access Code 2 to 4 AAAA (inactive)

- Access Code 3 BBBB (inactive)

- Access Code 4 CCCC (inactive)

- Duress Code OMIT, OMIT, OMIT, OMIT (inactive)

Note: The factory default Access Codes 02 to 04 and the Duress Code must be changed by USER 1 to a four-digit number to activate them.

Leaving Programming Mode

When all programming has been completed:

Key in ‘99’ at the keypad.

The display clears and the Day LED is ON.

The system is now in user mode.

Note: If there is a fault on the system, for example, an open tamper circuit, the display shows this and will not return to Day mode. Press Y (Clear) and rectify the faults.

Engineer Reset

To perform an Engineer Reset:

- Check that the display is showing the alarm condition. (Note: if the display shows “rr”, Press Clear twice.)

- Key in 0 followed by the Engineer’s code (default 7890), followed by 99.

The display goes blank and the Day LED glows.

Re-Entering Programming Mode

“Initial Power Up” describes how to enter programming mode for the first time in a new installation. If you wish to enter programming mode at any other time:

- Make sure the system is unset.

- Press 0, then key in the Engineer’s code (default 7890). The keypad gives an intermittent tone.

- Open the end station lid.

The display shows “E” (for ‘engineer’) and the intermittent tone stops.

You are now in programming mode.

Refreshing the NVM

- If the user and/or engineer codes are lost, or you want to revert to the factory default programming, then: First, remove mains power before opening the case, and then disconnect the battery.

- Identify and remove the NVM chip (IC4) on the main PCB (see Figure 1).

- Reconnect the battery, then reapply mains power.

- Refit the NVM chip (note the locator marker position, see Figure 1). The end station loads the factory default access codes (User 1: 1234, Engineer: 7890).

- Carry on to re-program the system.

Testing

You may test parts of the system by entering commands at the keypad. To carry out a test, make sure the system is in programming mode and then key in one of the following commands. Press Clear to end each test:

- 91 To test the external sounder/bell.

- 92 To test strobe output.

- 93 To test the internal sounder output.

- 94 To test the keypad sounder.

- 95 To test programmable output No. 1.

- 96 To test programmable output No. 2.

- 97 To carry out a system walk test. This allows the engineer to test all alarm devices. When a circuit is opened, the internal sounder(s) will emit a tone and the appropriate circuit LED lights.

Reading the Log

The control unit keeps a 60-event log of recent events. Each event is represented by a two-digit code, shown on the next page. To review the event log, make sure the system is in programming mode, then:

- Key in 90. The display shows the most recent event in the log, for example, “c7”. For a list of the log code, see the next page.

- Key in 1 to show earlier events or 3 to see more recent events.

- Press Clear to leave the log.

The table below shows all the messages that can appear in the event log.

The left-hand column shows the codes that appear on a keypad display.

Event Log Displays

- AA: Arm area A (full set)

- Ab: Arm area B (part set)

- Ac: Arm area C (part set)

- AE: Installer access

- AP: Auxiliary power failure

- bF: Battery fault

- c1: to c8 Zone violation

- cc: Communication successful

- cF: Communications failure

- E1: to E8 Entry via zone circuit

- EA: Entry alarm

- EF: Exit fault

- Lb: Low battery

- Lf: Telephone line failure

- Lt: End station lid tamper

- o1 to o8: Zone omitted

- PF: Mains power failure

- r1 to r4: Remote keypad back tamper

- rP: Remote keypad missing

- rr: Installer reset required

- rt: Remote keypad excess key presses tamper S1 to S8 Zone soak Test

- Sr: System reset (total power failure)

- t1 to t8: Zone tamper violation

- tr: Tamper return fault

- u1 to u9: Access user (u5 = Duress, u9 = keyswitch)

User Commands

- Set/Unset System: User code + A

- Part Set: User code + B or C

- Omit zone (1-8): User code + A, B or C + OMIT + Zone number

- Omit 24-hour zone: User code + OMIT + Zone number

- Reinstate omitted 24-hour zone: User code + OMIT + CLEAR

- Change User code: User code + 4 + old code + new code + CLEAR

- Read Log: User code + 5 + 1 to see earlier events or 3 to see later events + CLEAR + CLEAR

- Chime On/Off: User code + 7 + CLEAR

- Bell Test: User code + 8 + CLEAR to end test

- Walk Test User code + 9 + CLEAR to end test

Note: Duress code default is OMIT OMIT OMIT OMIT and is inactive until changed.

For more Manuals by Scantronic Security Systems, visit ManualsLibraryy

Scantronic 9800 Security Alarm System-FAQs

What is a security alarm system?

A security alarm system is designed to detect unauthorized entry into homes or buildings. It alerts owners or monitoring services through sound or notifications when a potential intrusion is detected.

Are Scantronic alarms reliable?

Yes, Scantronic alarms are known for high reliability and performance, trusted for over 30 years in the security industry for both residential and commercial protection.

How do I reset my Scantronic 9800 alarm if I forget the code?

To reset, turn off the main power and battery supply, then restore power while holding the reset or engineer button if available. If unsuccessful, contact a professional installer or your alarm provider for assistance.

What is the engineer code for a Scantronic alarm?

The default engineer access code is 7890. It allows technicians to access system settings and perform maintenance or configuration changes.

What are the main advantages and disadvantages of alarm systems?

Advantages: Increased home safety, deterrence of burglars, and real-time alerts.

Disadvantages: Initial installation costs, potential false alarms, and the need for regular maintenance.

What is the difference between CCTV and a security alarm system?

A CCTV system records and monitors video footage, while a security alarm detects intrusions and alerts users instantly. CCTV provides visual evidence; alarms offer immediate warnings.

How do I replace the battery in a Scantronic alarm panel?

Open the control panel with a suitable tool, disconnect the old battery, and replace it with a 12V rechargeable sealed lead-acid battery of the same capacity. Always power off the system before changing batteries.

How long do alarm systems typically last?

Most alarm systems, including the Scantronic 9800, last between 10–15 years with proper maintenance and periodic battery replacements.