Sullair R02 Supervisor Controller

Section 2

DESCRIPTION

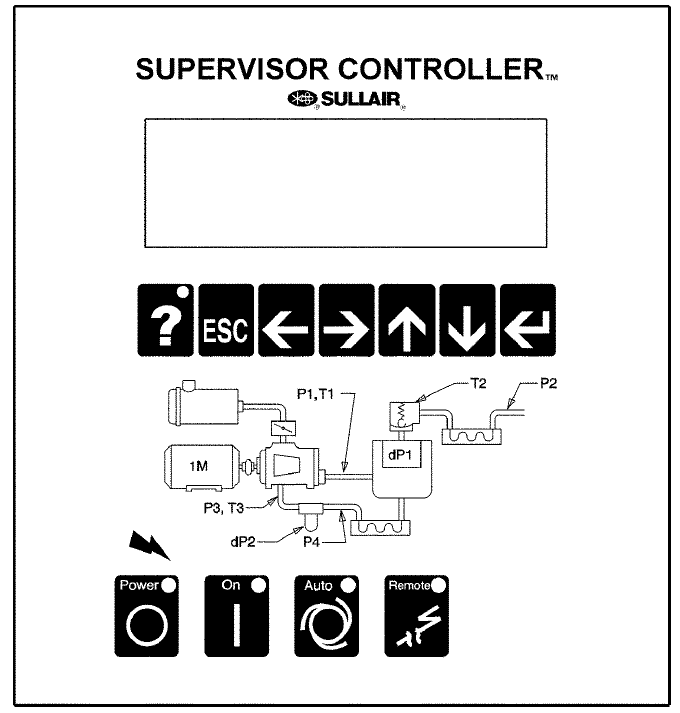

SUPERVISOR KEYBOARD LAYOUT

Refer to Figure 2-1. The Display module has eleven keys grouped in two rows. The top row has the following seven keys :

- Help key, used to display possible causes of and correction for an alarm or fault.

- Returns to the main display.

- Used to edit text or numbers (move cursor left).

- Used to edit text or numbers (move cursor right).

- Used to change numbers or text, or scroll.

- Used to change numbers or text, or scroll.

- Used to select an item from a menu, or start

MAIN DISPLAY

- Line 1—Machine state

- E-Stop—E-Stop button pressed, or auxiliary E-Stop present.

- Stopped—Machine not running.

- Unloaded—Machine running unloaded.

- Loaded—Machine running, loaded, and modulating.

- Full Load—Machine forced to full load. (Used only in sequencing modes).

- Remote Stop—The compressor is off but armed to start. The machine will start when the remote start contact is closed.

- NOTE: the machine may start at any time.

- Seq Stop—The compressor is off but armed to start. The machine will start when the sequencing conditions meet the criteria to start.

- NOTE: the machine may start at any time.

- Trim—Machine running, loaded, and modulating in a sequenced system.

- Line 2—Fault or Warning, blank means no fault or warning is present. If there are multiple alarms, they will be shown for 2 seconds each. If an alarm is active, pressing the ‘?’ key will give troubleshooting information on that alarm.

- Line 3—P2—Line pressure

- Line 4—T1—Discharge Temperature

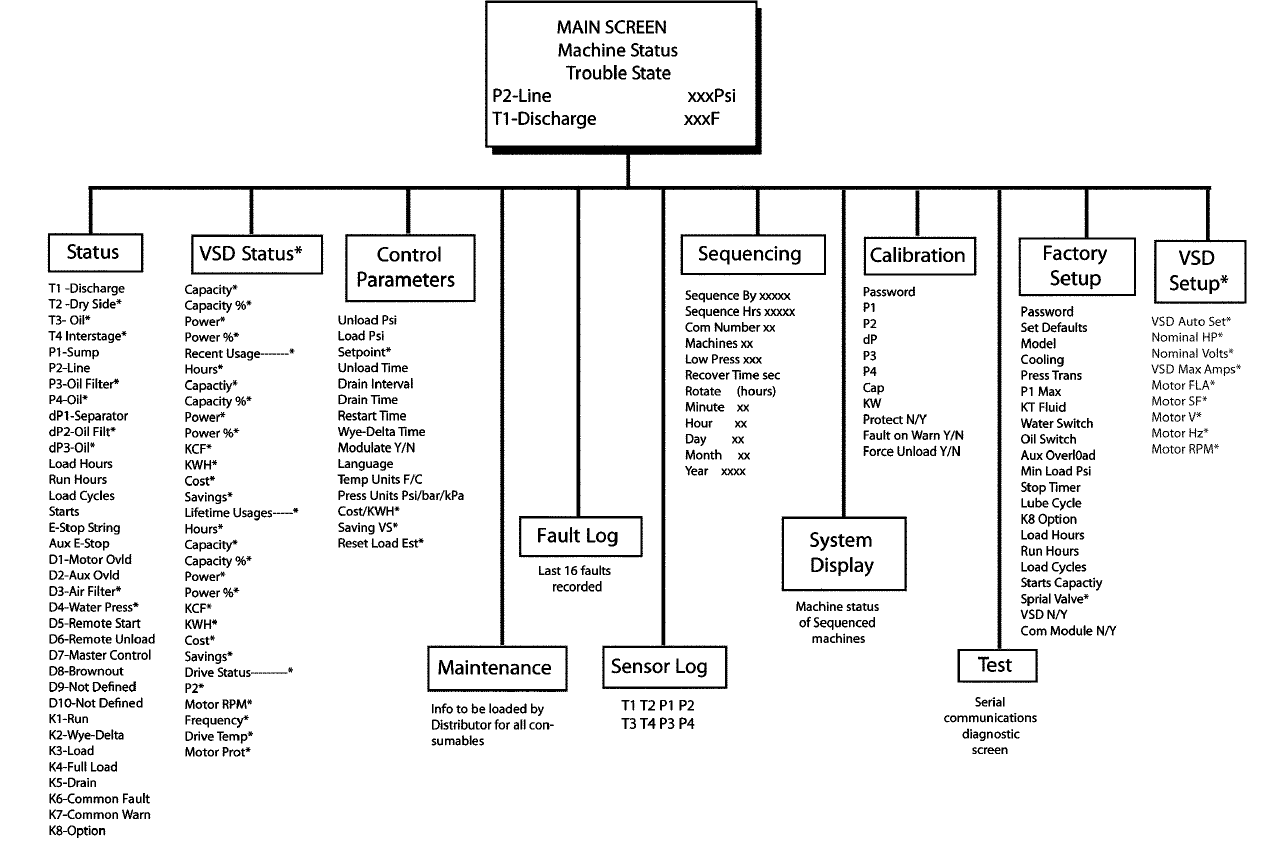

FUNCTION MENU

While in the main display, if any of the arrow keys are pressed, the function menu is displayed. This menu is used to view the status or edit parameters. The function menu has the following entries :

- Status—Current pressures, temperatures, inputs and outputs.

- VSD Satus—(VSD packages only) See Section 6.

- Control Parameters—Pressure and temperature and timer settings.

- Maintenance—Preventive maintenance information and timers.

- Fault Log—Log of previous faults.

- Sensor Log—Log of sensor readings leading up to a fault.

- Sequencing—Sequencing parameters.

- System Display—Display of modes of machines in a sequencing system.

- Calibration—Correction factors for pressures.

- Test—Used by Sullair personnel for troubleshooting serial communications.

- Factory Setup—Model settings.

- VSD Setup—(VSD Packages only) See Section 6. To select a function, use the up and down arrow keys to scroll to the desired function as indicated on the last

line of the display, then press the enter key

STATUS—CURRENT PRESSURES, TEMPERATURES, INPUTS AND OUTPUTS

All inputs and outputs are displayed showing both the designator and the description (eg. T1- Discharge) along with the selected temperature (C or F) or pressure (psi, bar, kPa) units. Digital inputs and outputs are shown either as a ‘0’ (zero) or ‘1’ (one). Zero is off and one is on. This is a view-only display. The order of display is :

- Temperatures—T1 through T4 depending on model.

- Pressures—P1 through P4 depending on model.

- Delta pressures—dp1 through dp3 depending on model.

- Load Hours—Hours machine has run loaded.

- Run Hours—Hours the machine has run loaded or unloaded.

- Load Cycles—Number of load/unload cycles.

- Starts—Number of times the machine has started.

- E-Stop String—E-Stop push button.

- Aux E-Stop—Auxiliary E-Stop, wired by the customer.

- Digital Inputs—D1 through D10, depending on model.

- Relay Outputs—K1 through K8, depending on model.

MAINTENANCE— PREVENTIVE MAINTENANCE FORMATION AND TIMERS

The following lines are on the Maintenance display.

- Information—The top two lines may be changed to advise what to do when there is a maintenance warning. For example, a distributor can put in his name and telephone number.

- Ser. No—Serial number of machine.

- Warn at—When the following drops below this number, a warning is issued.

- Oil Filter hours—Hours before oil filter change.

- PN—Oil Filter part number.

- Separator hours—Hours before separator change.

- Prim.—Primary separator part number.

- Sec.—Secondary separator part number.

- Air Filter hours—Hours before air filter change

FAULT LOG—LOG OF PREVIOUS FAULTS

- The fault log shows the last 16 faults that occurred. The top line of the display shows the run hours where the fault occurred, and the second line shows the

fault. The faults can be scrolled through using the up and down arrow keys. They are ordered by the most recent first. (ie. when the function is entered the most

recent fault is displayed. Pressing the down arrow displays the previous fault etc).

FACTORY SETUP- MODEL SETTINGS.

- The factory setup display is used by Sullair personnel to initially set up the machine. The following values reflect the machine configuration.

- Model—Model number of machine.

- Cooling—Air or Water.

- Press Trans—Pressure transducer range 200, 250, 500.

- P1 Max—Maximum discharge pressure.

- KT Fluid—Yes or No, indicating fluid.

- Water Switch—Water pressure switch, Yes or No.

- Oil Switch—Oil pressure differential switch, Yes or No.

Table 2-1: Supervisor Controller Menu Tree

Section 3

START-UP PROCEDURES

MOTOR ROTATION DIRECTION CHECK

- After the electrical wiring has been done, it is necessary to check the direction of the motor rotation. With the control system in MANUAL mode, Press the

and

and  pads in succession to bump start the compressor. When looking at the motor from the end opposite the compressor unit, the shaft should be turning clockwise on all gear-driven models, and counterclockwise on direct-drive models.

pads in succession to bump start the compressor. When looking at the motor from the end opposite the compressor unit, the shaft should be turning clockwise on all gear-driven models, and counterclockwise on direct-drive models. - If the motor shaft is not turning in the proper direction, disconnect the power to the starter and exchange any two of the three power input leads, then recheck rotation. A “Direction of Rotation” decal is located on the coupling guard between the motor and compressor to show proper motor/compressor rotation.

- Variable speed drive packages will have the main motor direction set at the time of construction, but the fan direction is affected by the installation. If fan-cooled, ensure that fan rotation is correct. To change direction, disconnect the power, and exchange any two of the three fan motor leads at the fan motor

starter.

INITIAL START-UP PROCEDURE

The following procedure should be used to make the initial start-up of the compressor.

- Be sure that all preparations and checks described in the Installation Section have been made.

- Read the preceding pages of this manual thoroughly.

- Jog motor to check for correct rotation of the fan (refer to Section 3.1).

- Start the compressor in the desired operating mode

.

. - Slowly open the shut-off valve to the service line.

- Check for possible leaks in the piping.

- Slowly close the shut-off valve to ensure the proper nameplate pressure unloading setting is correct. The compressor will unload at nameplate pressure. If adjustments are necessary, see the Control System Adjustment section in the compressor operator’s manual.

- Observe the operating temperature. Refer to the compressor operator’s manual for an acceptable operating range. If the temperature exceeds this range, the cooling system and installation environment should be checked.

- Open the shut-off valve to the service line.

- Reinspect the compressor for temperature and leaks the following day.

TROUBLESHOOTING

TROUBLESHOOTING INTRODUCTION

- The information contained in the Troubleshooting chart has been compiled from factory experience. It contains symptoms and usual causes for the described problems. However, DO NOT assume that these are the only problems that may occur. All available data concerning the trouble should be systematically analyzed before undertaking any repairs or component replacement procedures. A detailed visual inspection is worth performing for almost all problems and may avoid unnecessary additional damage to the compressor. Always remember to:

- a. Check for loose wiring.

- b. Check for damaged piping.

- c. Check for parts damaged by heat or an electrical short circuit, usually apparent by discoloration or a burnt odor. Should your problem persist after making the recommended check, consult your nearest Sullair Distributor or the Sullair Corporation factory Service Department.

| Table 4-1: Troubleshooting Guide—Supervisor Controller | ||||

| Message | Model | Enable | Probable Cause | Remedy |

| Air Filter Maint | ALL | ALWAYS | Differential Pressure Across Inlet Filter High | Replace filter |

| Check inlet filter pressure switch. | ||||

| Aux Motor Overload | ALL | ALWAYS | Auxiliary Motor Tripped on Cooling Fan, Oil Pump or Other Motor | Reset auxiliary overload after heater element cools. Verify correct motor amps. |

| Check for loose connections | ||||

| Check motor starter contact for proper operation. | ||||

| Check line voltage, if low consult power company. | ||||

| E-Stop | ALL | ALWAYS | E-Stop Button Active | Release button. |

| E-Stop Push Button | Check wiring | |||

| Message | Model | Enable | Probable Cause | Remedy |

| E-Stop | ALL | ALWAYS | Auxiliary E-Stop String Open | Check auxiliary E-Stop devices. |

| E-Stop String | Check wiring. | |||

| Low Water Pressure | ALL | Water- cooled | Cooling Water Pressure Below 10 psi (0.7bar) | Check for closed valves or broken pipes. |

| Oil Change Due, Oil Filter Change, Separator Change Due, Air Filter Change, Oil Analysis Due, Maintenance Due | ALL | ALWAYS | Maintenance Due | Select Maintenance from the menu to see service due and part numbers. |

| Main Motor Overload | ALL | ALWAYS | Main Motor Overload | Reset overload after the heater element cools down. |

| Make sure the compressor is properly configured. | ||||

| Make sure load pressure is set below the limit of a compressor. | ||||

| Check motor starter contacts for proper operation. | ||||

| Check line voltage, if low consult power company. | ||||

| I/O Mod Com Error, Com Mod Com Error, Motor Mod Com Error, VSD Com Error | ALL | ALWAYS | Module Network Error; The Network that Connects the Display Module, I/O Mod- ule and Other Optional Modules is Not Working Correctly | Check wiring. |

| Replace the module referred to in the error message, if the problem persists replace the display module. | ||||

| Oil Filter Maint., dP2 Oil Filter High | ALL | ALWAYS | Pressure Across Oil Filter Above 20 psi (1.4 bar) While Running | The oil filter is clogged, replace oil filter. |

| FLOODED | ALWAYS | Low ambient temperature, a sump heater may be required in ambients below 40°F (4°C). | ||

| ALL | ALWAYS | Sensor failure, check sensor, wiring and tubing. |

| Table 4-1: Troubleshooting Guide—Supervisor Controller | ||||

| Message | Model | Enable | Probable Cause | Remedy |

| P3 Oil Pressure Low, dP3 Oil Pressure Low | ALL | ALWAYS | Oil Pressure Low | Oil pump failure, consult Sul- lair service department. |

| The oil filter is clogged; replace oil filter. | ||||

| FLOODED | ALWAYS | Sump oil level low, replenish oil to proper level. | ||

| Low ambient temperature, a sump heater may be required in ambients below 40°F (4°C). | ||||

| An oil pump may be required for remote coolers. | ||||

| P1 Sensor Fail, P2 Sensor Fail, P3 Sensor Fail, P4 Sen- sor Fail, T1 Sensor Fail, T2 Sensor Fail, T3 Sensor Fail, T4 Sensor Fail, T5 Sensor Fail | ALL | ALWAYS | Sensor or Wiring Failure | Check sensor wiring. |

| Check sensor. | ||||

| dP1 Separator High | FLOODED | ALWAYS | Pressure Across Separator High | Plugged separator elements, replace. |

| Pressure sensor failure, check sensor wiring. | ||||

| Factory Setup Error | ALL | ALWAYS | The Factory Setup Information Needs to be Reviewed for Correct Values | If the problem persists replace the Supervisor. |

| P1 Sump Pressure High | FLOODED | ALWAYS | Sump Pressure High (Pop-pet, Sullicon, Spiral, Blow-, or Pneumatic Valve Failed) | Check valves. Check Sulli- con adjustment (see Control Adjustment section in the compressor operator’s manual). |

| Solenoid valves, check operation and wiring. | ||||

| ALL | ALWAYS | Pressure regulator, check adjustment, and operation. | ||

| FLOODED | ALWAYS | Check the minimum pressure check valve (not applicable to oil-free compressors). | ||

| Table 4-2: Analog Alarms (Flooded Screw Compressors Less Than 200 psi) | ||||||

| Sensor | Type | Limit | Start Delay | Run Delay | Check (*) | Comment |

| P_1 | High Inhibit | 5 | 0 | 0 | At Start | High sump psi at the start |

| P_1 | Low Fault | 5 | 0 | 0 | When Running | Immediate Fault |

| P_1 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| P_2 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| P_3 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| P_4 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| T_1 | Low Fault | -40 | 0 | 0 | Constantly | Sensor failure fault |

| T_1 | High Fault | 225 | 5 | 30 | Constantly | Delayed for temp spikes |

| T_1 | High Fault | 235 | 5 | 30 | Constantly | Delayed for temp spikes |

| T_1 | High Fault | 245 | 0 | 0 | Constantly | Immediate Warning |

| T_1 | High Fault | 255 | 0 | 0 | Constantly | Immediate Fault |

| T_1 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| T_2 | Low Fault | -40 | 0 | 0 | Constantly | Sensor failure fault |

| T_2 | High Warn | 225 | 5 | 30 | Constantly | Delayed for temp spikes |

| T_2 | High Fault | 235 | 5 | 30 | Constantly | Delayed for temp spikes |

| T_3 | Low Warn | -40 | 0 | 0 | Constantly | Sensor failure warning |

| T_3 | High Warn | 500 | 0 | 0 | Constantly | Sensor failure warning |

| T_4 | Low Fault | -40 | 0 | 0 | Constantly | Sensor failure fault |

| T_4 | High Fault | 500 | 0 | 0 | Constantly | Sensor failure fault |

| (*) In the ‘Check’ column above, alarms are checked: Constantly—if the machine running or stopped When Running—if the machine is running If Enabled—if the parameter is non-zero At Start—will not allow start if alarm present Over Min Psi—the machine is loaded and above min load pressure | ||||||

| Table 4-5: Machine Power Outage Behavior | ||||

| Seq. Mode | Local/ Remote | Remote Start/ Stop | Run Mode | Action (State) |

| Disabled | X | X | Cont | Manual Stop |

| Disabled | X | X | Auto | Start after Restart delay & P2 < Load psi, & P1 < 5 psig |

| Remote | Local | X | Cont | Manual Stop |

| Remote | Local | X | Auto | Start after Restart delay & P2 < Load psi, & P1 < 5 psig |

| Remote | Remote | Off | Cont | Remote Stop |

| Remote | Remote | Off | Auto | Remote Stop |

| Remote | Remote | On | Cont | Start after Restart delay |

| Remote | Remote | On | Auto | Start after Restart delay & P2 < Load psi, & P1 < 5 psig |

| Note: ‘xxxx’ means ‘has no effect’. | ||||

SECTION 6

VARIABLE SPEED DRIVE

OVERVIEW

- The Sullair VSD drive application is custom-designed for the operation of air compressors. All necessary control functions are performed through the Supervisor keypad. The drive functions as a module on the Supervisor communications bus.

| Table 6-1: Conductor and Fuse Sizes (380/460V) | ||||||

| HP | Size (A) | Fuse (A) | Wire Size Power (75oC Rated Wire) | Wire Size Ground | Wire Size Power (90oC Rated Wire) | Wire Size Ground |

| 15 | 23 | 30 | 10 | 10 | 10 | 10 |

| 20 | 31 | 35 | 8 | 8 | 8 | 8 |

| 25 | 38 | 50 | 6 | 8 | 8 | 8 |

| 30 | 46 | 60 | 4 | 8 | 6 | 8 |

| 40 | 61 | 80 | 2 | 6 | 2 | 6 |

| 50 | 72 | 100 | 2 | 6 | 2 | 6 |

| 60 | 87 | 110 | 1 | 6 | 2 | 6 |

| 75 | 105 | 125 | 1/0 | 4 | 1 | 6 |

| 100 | 140 | 175 | 3/0 | 2 | 2/0 | 2 |

| 125 | 170 | 200 | 4/0 | 1/0 | 4/0 | 1/0 |

| 150 | 205 | 250 | 300 | 2/0 | 4/0 | 1/0 |

| 200 | 261 | 350 | 2×4/0 | 3/0 | 2×2/0 | 2/0 |

| 250 | 385 | 400 | 2×250 | 300 | 2×3/0 | 3/0 |

| 300 | 385 | 450 | 2×250 | 300 | 2×250 | 300 |

| 350 | 460 | 500 | 2×300 | 300 | 2×300 | 300 |

| 400 | 520 | 600 | 2×400 | 350 | 2×350 | 300 |

| 450 | 590 | 6×350 | 2×500 | 500 | 2×400 | 400 |

| Table 6-2: Conductor and Fuse Sizes (575V) | ||||||

|

HP |

Size (A) |

Fuse (A) | Wire Size Power (75oC Rated Wire) | Wire Size Ground | Wire Size Power (90oC Rated Wire) | Wire Size Ground |

| 15 | 18 | 30 | 10 | 10 | 10 | 10 |

| 20 | 27 | 40 | 8 | 8 | 8 | 8 |

| 25 | 34 | 45 | 6 | 8 | 8 | 8 |

| 30 | 34 | 45 | 6 | 8 | 8 | 8 |

| 40 | 52 | 70 | 4 | 6 | 4 | 6 |

| 50 | 62 | 80 | 2 | 6 | 2 | 6 |

| 60 | 80 | 125 | 1/0 | 6 | 1 | 6 |

| 75 | 100 | 150 | 2/0 | 6 | 1/0 | 6 |

| 100 | 125 | 175 | 3/0 | 6 | 2/0 | 2 |

| 125 | 144 | 250 | 300 | 1/0 | 4/0 | 1/0 |

| 150 | 170 | 250 | 350 | 2/0 | 300 | 1/0 |

| 200 | 208 | 275 | 350 | 2/0 | 300 | 1/0 |

| 250 | 261 | 350 | 2×4/0 | 3/0 | 2×2/0 | 2/0 |

| 300 | 325 | 400 | 2×250 | 300 | 2×250 | 300 |

| 350 | 385 | 450 | 2×300 | 300 | 2×300 | 300 |

| 400 | 460 | 6×250 | 2×300 | 300 | 2×300 | 300 |

| 450 | 460 | 6×250 | 2×300 | 300 | 2×300 | 300 |

| *UL Recognized Type RK *Use only copper wire with a minimum temperature rating of 75*C *Based on a Maximum environment of 104*F (40*C) *Refer to NEC Article 310 for Proper Conductor Size Requirements | ||||||

INSTALLATION

This variable speed AC drive has been properly mounted, adjusted, and tested prior to shipment of the compressor package. Inspect the unit to ensure it was not damaged during shipment. The package provides a terminal block for the connection of three-phase power and ground. Refer to the package wiring diagram for specific connection information. All internal wiring to the drive and motors has been provided by the factory, per the drive’s requirements. Do not alter factory wiring. To ensure proper wiring to the package, use the following guidelines:

- Use heat-resistant copper cables only, +75°C or higher.

- The minimum input line cable and line fuses must be sized per the rated input current of the unit. See Table 6- 1.

- Consistent with UL listing requirements, for maximum protection of the variable speed drive, use UL-recognized fuses, type RK5.

- Suitable for circuits delivering fault currents up to 100,000A.

FAULT AND WARNING CODES

| Fault | Possible Cause | Solution |

| VSD Param Lim Fault | Incorrect model, HP or Voltage selected in Factory & VSD Setup | Make proper selections |

| VSD Com Error | Communications lost with the VSD | Check connections to the VSD. Check VSD control power and check for board faults. |

| VSD Emergency Stop (VSD Code 51) | Emergency Stop is pressed Break in Estop wiring | Clear the package emergency stop. Check Estop wiring to the drive input. |

| VSD Com Fault (VSD code 53) | Communication problems detected and reported by the VSD | Check connections to the VSD. Check VSD control power and check for board faults. |

| Drive Fault xx | Problem reported by the VSD | Refer to the fault codes in the table below |

| Drive fault codes are used for least-like faults. The Supervisor will display these as “Drive Fault” with a code number. If a keypad service tool is plugged into the drive, it will display the fault code and the fault name shown in the first two columns. | ||

| Code | Fault | Possible Cause | Solution |

| 1 | Overcurrent | The variable speed drive has detected a high current (>4xIn) in its output due to: • sudden heavy load increase • short in the motor • short in the cables to the motor • unsuitable motor | Check loading. Check motor. Check cables. |

| 2 | Overvoltage | The DC-link voltage has exceeded its high limit due to: • too short a deceleration time • high voltage levels or surges in the utility supply | Make the deceleration time longer. Use a chopper and brake resistor. Correct utility supply voltage (level is too high). Add input impedance to limit surges. |

| 3 | Ground Fault (Earth Fault) | Current sensing indicates that the sum of motor phase currents is not zero. • insulation failure in motor or motor cables | Remove faults from ungrounded systems. Check the motor and motor cables. |

| 5 | Charging Switch | The charging switch was open when the START command was been given due to: • faulty operation • component failure | Reset the fault and restart. Should the fault re-occur, contact Sullair service |

CLEANING VSD HEAT SINKS

- Always read the safety section in your manual for your machine. Properly lock out/tag out the machine before work begins on Frames 4 – 10. VSD Drives

can store a capacitive charge. Failure to follow correct shutdown and lockout/tag out procedure can result in serious injury or death

FAN REMOVAL AND REPLACEMENT 1-15 HP/480V:

- Remove the front cover of the VSD.

- Remove incoming power lead, motor leads, and communication wire to VSD.

- You will need to remove the VSD from the unit. It will either be flange mounted or bolted to the panel. Remove the drive and set it on the back.

- Remove the fan by taking a screwdriver and pushing in on the two side tabs then pull up. The fan needs to be removed with caution so the electrical connections are not damaged.

- Clean the fan of dirt and debris or install a new fan assembly

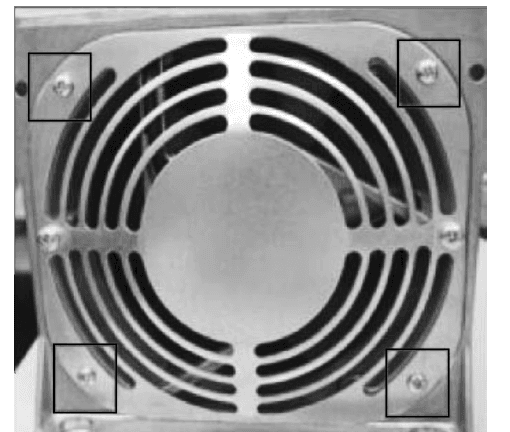

FAN REMOVAL AND REPLACEMENT 20-40 HP/480V:

- Remove the front cover of the VSD.

- Remove incoming power lead, motor leads, and communication wire to VSD.

- You will need to remove the VSD from unit. It will either be flange mounted or bolted to the panel. Remove the drive and set on its back.

- Remove the fan by unscrewing the four mounting screws.

- Remove the blue control box on the front of the VSD and the metal cover underneath it. Be sure to not allow any debris to enter VSD.

- Unplug the fan connector and push the wire through the hole in VSD. Remember the fan is on an x17 connection

- Remove the fan from the VSD.

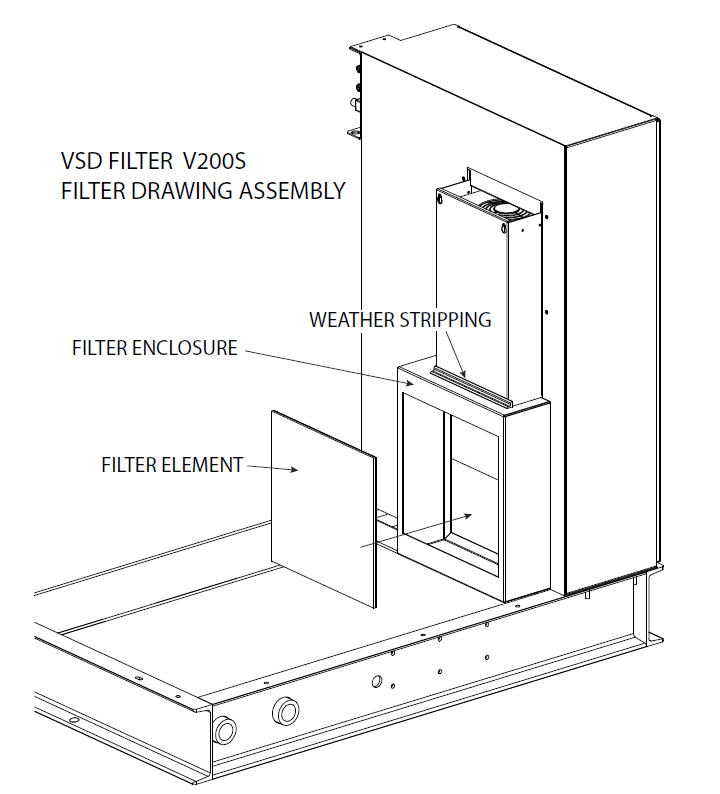

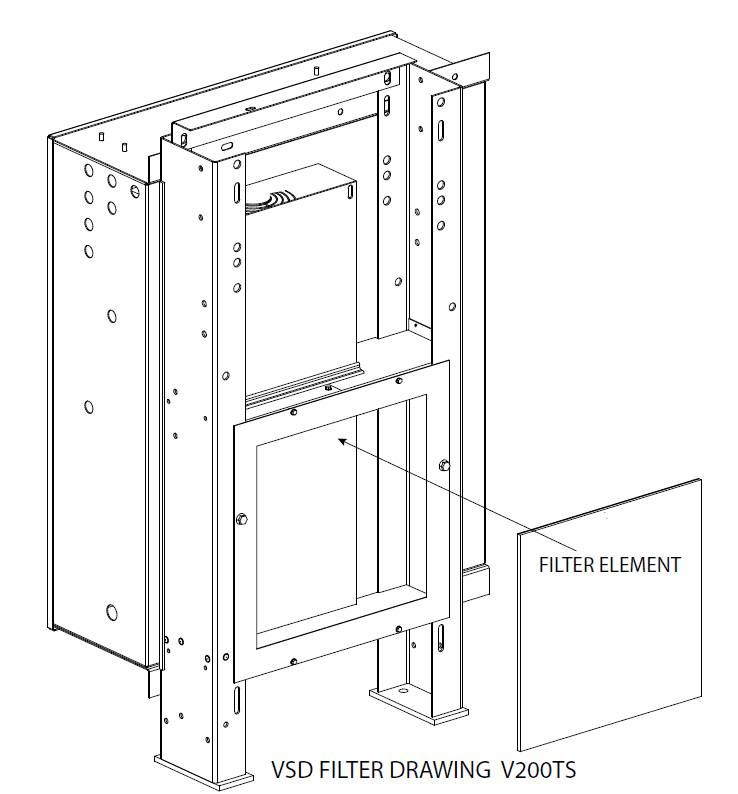

VSD FILTER CLEANING

- Locate the VSD filter from the following figures.

- Remove the filter from the assembly. (The filters are magnetic and should pull off easily.)

- With a water hose, spray the filter from the magnet side.

- Let the filter thoroughly dry.

- Replace the filter on the VSD assembly

For more manuals by Sullair visit, ManualsLibraryy

Sullair R02 Supervisor Controller-FAQs

What is the Sullair R02 Supervisor Controller?

The Sullair R02 Supervisor Controller is an advanced system designed to monitor and control air compressor operations, ensuring efficiency and reliability.

How do I reset the Sullair R02 Controller?

To reset the controller, navigate to the settings menu, locate the reset option, and follow the on-screen instructions. Always refer to the manual for specific steps.

What alerts does the R02 Controller provide?

The controller displays alerts for system faults, maintenance reminders, pressure changes, and other operational issues to help prevent downtime.

Can I adjust pressure settings on the Sullair R02?

Yes, the controller allows you to configure and adjust pressure settings based on system requirements. Ensure changes comply with operational guidelines.

How do I troubleshoot errors on the R02 Controller?

Check the display for error codes and refer to the manual for troubleshooting steps. Common solutions include checking power supply, connections, and system pressure.

Does the Sullair R02 support remote monitoring?

Depending on the model, the R02 Controller may support remote monitoring features, allowing users to track performance and receive alerts from a connected system.

How often should I perform maintenance on my compressor with an R02 Controller?

Regular maintenance schedules vary based on usage, but the controller will notify you when servicing is required, helping to maintain optimal performance.

Can the Sullair R02 be integrated with other systems?

Yes, the R02 Controller is designed for seamless integration with compatible industrial systems for enhanced automation and efficiency.

What should I do if the controller stops responding?

Try restarting the unit and checking power connections. If the issue persists, consult the manual or contact Sullair support for assistance.