White 1418 Portable Sewing Machine

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using (this sewing machine)

DANGER: To reduce the risk of electric shock:

An appliance should never be left unattended when plugged in. Always unplug this appliance from the electric outlet immediately after using and before cleaning. Always unplug before relamping. Replace the bulb with the same type rated 15 watts.

WARNING: To reduce the risk of burns. Fire, electric shock, or injury to persons:

- Do not allow it to be used as a toy. Close attention is necessary when this appliance is used by or near children.

- Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the man. The manufacturer is contained in this manual.

- Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or service center for examination, repair, or electrical or mechanical adjustment.

- Never operate the appliance with any air openings blocked. Keep the ventilation · openings of the sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

- Never insert or drop any object through any opening.

- Do not use outdoors.

- Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

- To disconnect, turn all controls to the off (“O”) position, then remove the plug from the outlet.

- Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

- Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

- Always use the proper needle plate. The wrong plate can cause the needle to break.

- Do not use bent needles.

- Do not pull or push fabric while stitching. It may deflect the needle, causing it to break. ·

- Unplug the sewing machine when making any adjustments in the needle area, such as ~hreading needle, changing needle, threading bobbin, or changing presser foot, etc.

- Always unplugthe he sewing machine from the electrical outlet when removing covers, lubricating, or making any other user servicing adjustments mentioned in the instruction manual.

SAVE THESE INSTRUCTIONS

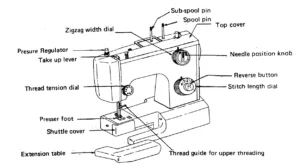

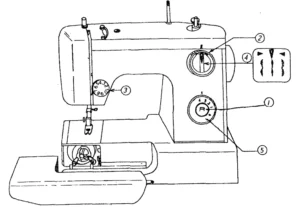

NAME OF PARTS

(FRONT VIEW)

{REAR VIEW)

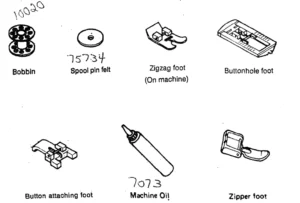

ACCESSORIES

BEFORE SEWING

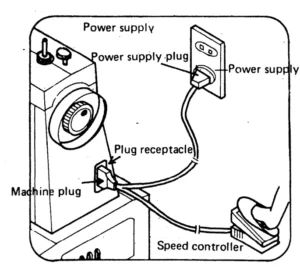

- Fit the plug into the machine..

- Plug the machine into the power supply.

- Sewing speed can be varied by the foot control.

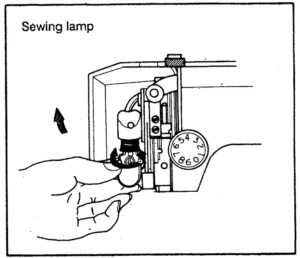

REMOVE OR INSTALL BULB

- Open the face cover in the direction of the arrow.

- Remove the bulb by unscrewing it counter-clockwise.

- Install a new bulb by screwing it in clockwise.

- Use a screw type bulb with 120V /15W(Max).

IMPORTANT: When leaving the sewing machine unattended, the plug must be removed from the socket outlet.

When servicing the sewing machine, or when removing covers or changing lamps, the machine must be disconnected from the supply by removing the plug from the socket outlet.

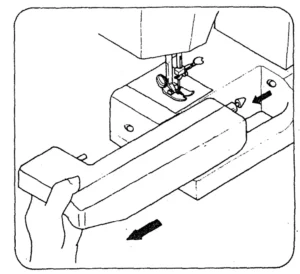

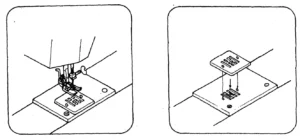

REMOVING EXTENSION TABLE

- Hold the left end of the tabie and pull out in the direction of the arrow.

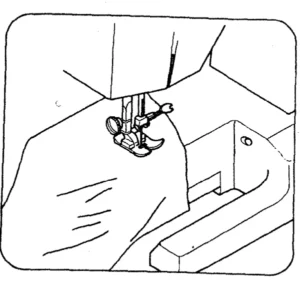

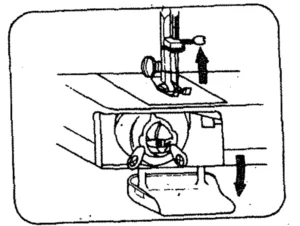

FREE-ARM SEWING

- This sewing machine can be used as a flat bed machine, but can easily be converted to e arm machine by removing the extension table.

- Especially useful for sewing sleeves, pant legs, tubular fabrics ·etc, or easier.

- To see tubular, just slip the sleeve or leg of pants onto the free arm as shown on the side.

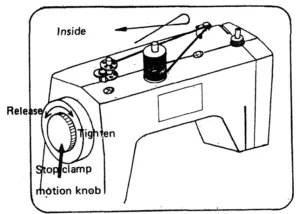

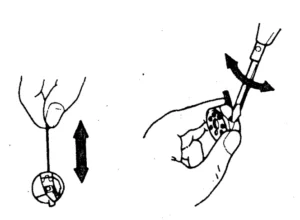

WINDING THE BOBBIN

- release stop motion knob.

- Thread as shown.

- When the bobbin is filled, tighten the stop motion knob.

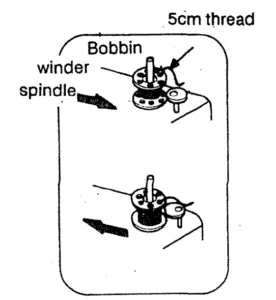

Push the bobbin winder spindle in the direction of the arrow.

When bobbin winding is completed, return the spindle to its original position.

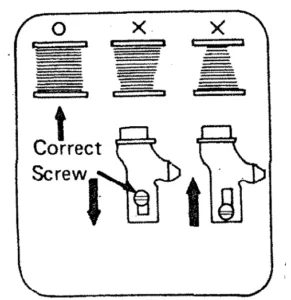

When bobbin winding is incorrect, release. The screw of the upper thread guide and adjust up or down until the bobbin winding is balanced.

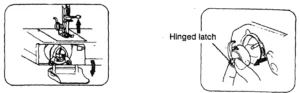

REMOVING BOBBIN CASE AND BOBBIN

- Raise the needle to its highest position and open the shuttle race cover.

- Open the hinged latch of the bobbin case and pull the bobbin case out of the machine.

- Release the latch, and the bobbin will jell out easily.

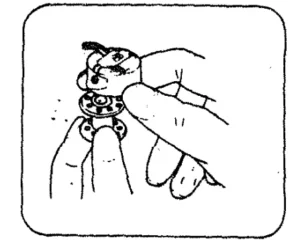

INSERTING BOBBIN INTO BOBBIN CASE

- Pull off 5cm of thread from the bobbin and insert it into the bobbin case as shown.

- Guide the end othe f the thread into the slot.

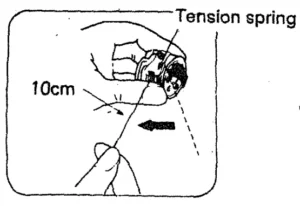

- Pull into the slot and under tension the ring and draw out about 10cm of thread.

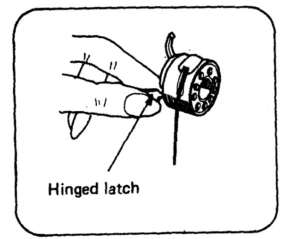

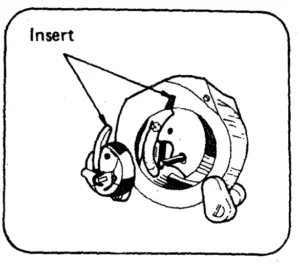

INSERTING BOBBIN CASE INTO SHUTTLE RACE

- Raise the needle to its highest position, pulling the thread to the front, open the latch of the bbincase, and hold it.

- Holding the latch open, place the bin case the ntre pin in the shuttle and release the latch.

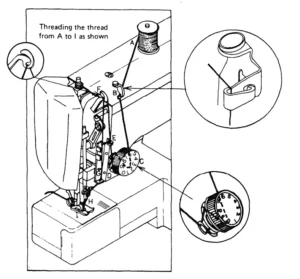

THREADING UPPER THREAD

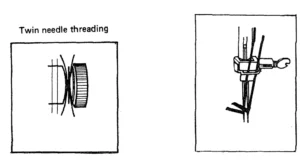

Twin needle threading

DRAWING UP BOBBIN THREAD

- Hold the upper thread with your left hand, turn the hand wheel slowly towards you until the needle goes down and comes up. Then stop ·the hand wheel ·when take-up-upp lever is at its highest position. Lightly draw up the upper thread, nd the lower thread will be brought up in a loop.

- Pull out both threads and place them together under the presser foot to the rear of the machine.

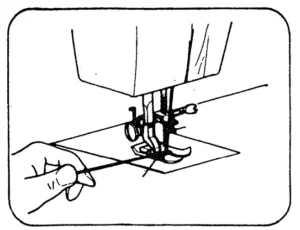

- Place fabric under the presser foot from the front, and lower the presser foot.

- Start to sew (see page 16)

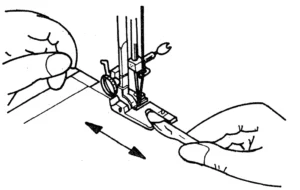

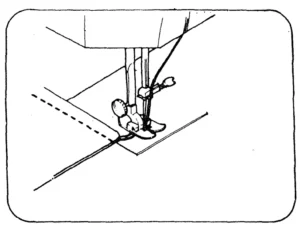

CHANGING SEWING DIRECTIONS

- Lower the needle down into the fabric and raise the er foot, pivot the fabric around the needle to change direction as desired.

- Lower. Press the foot and start to sew.

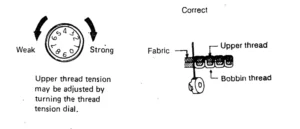

CONTROL DIAL

- Reverse button

- Zig-zag width dial

- T.hread tension dial

- Needle position knob

- Stitch length dial

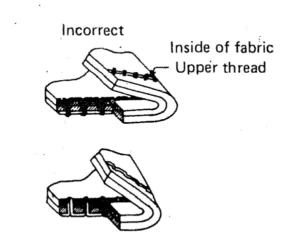

ADJUSTING THREAD TENSION

LOWER THREAD TENSION

Lower thread tension can be adjusted by turning screwthe on bobbithe n case slightly to the right (clockclockwiseincrease tension. Turn the screw (counterclockwise) to the left to decrease tension.

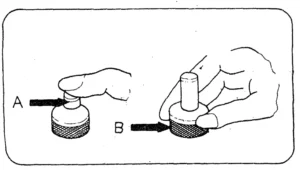

REGULATING THE PRESSURE FOOT PRESSURE

- Push down the inner pin (A) to increase pressure. (Light to medium fabrics).

- Push down the outer ring to release pressure. (Heavy fabrics)

- Insufficient pressure may cause poor feeding, skipped stitches, or difficulty in guiding the fabric.

- No pressure adjustment is required when darning or sewing embroidery.

DROP FEED

Note: Darning plate can be purchased separately.

There are a few times when you want to control the feeding of fabric by yourself. Raise the needle to its highest position and raise the er foot, pla. Placing a plate over the needle, · plate is two plates with a diameter with holesneedle.

You may then determine the movement of the fabric by yourself. See page 22 for button sewing application.

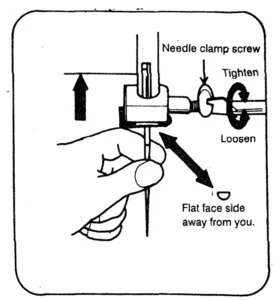

CHAN..GING NEEDLE

- Raise the needle bar to its highest position.

- Loosen theeedie clamp screw and remove the old needle.

- With the flat side of the needle facing away from you, insert the needle as far up as it will go.

- Tighten the needle clamp screw securely.

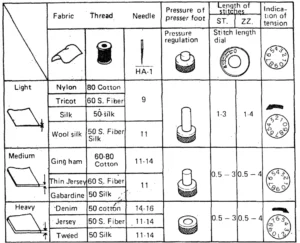

FABRIC THREAD NEEDLE TABLE

Please note that the following list is a guide when sewing different fabrics.

TO START SEWING

Important Hints

- Raise the take-up lever to its highest position before starting and after stopping sewing.

- Ho!d both threads about 10 ems to the rear of the machine for the first two or three stitches:

- Sufficient fabric should be placed under the needle before lowering the presser foot. ·

- Press the foot and start to sew.

- Test the machine stitches. On a scrap of fabric,, you plan to use, adjust the machine for the length of stitch and tension suitable for your fabric.

Attention

- When turning the balance wheel manually, always turn it toward you.

- Guide the cloth gently with your hand.

- To prevent breaking the needle,, always raise the needle out of the fabric when you stop sewing.

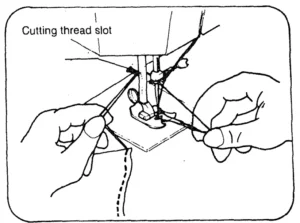

TO FINISH SEAM

- neww to the edge of sethe am.

- Push the reverse button and sew in reverse for about 3-4 ems.

- Aaise needle to its highest position.

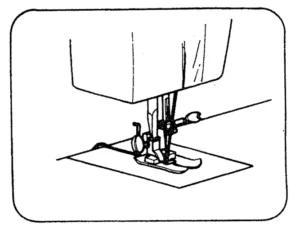

- Lift the presser foot and pull· out the fabric to the rear of the machine.

- Cut threads as shown on the thread cutter.

STRAIGHT STITCH

- This type of stitching is the one used most frequently.

- The zig-zag presser foot can be used for both straight and zig-zag sewing.

- For SE1wing light fabric, use a smaller stitch size. (Refer to page 15 for dial setting).

ZIGZAG SEWING

Satin stitching can be used for sewing initials. Patterns, applique, etc.

BUTTON SEWING

- Lower drop feed.

- Place the button, attaching the presser foot in position.

- Place the button between the presser foot and the fabric and lower the presser foot.

- Manually turn the hand wheel towards you, ensuring that the needle enters.Both holes of the button without obstruction.

(Increase or decrease the width setting). - Sew about 7 stitches.

- Pull both threads to the underside and tie them together.

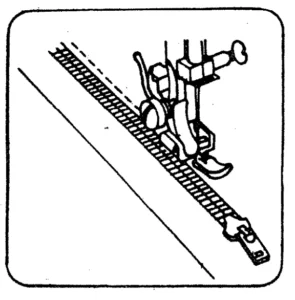

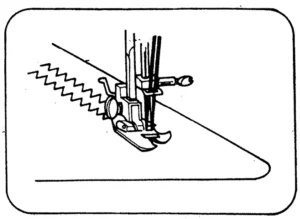

ZIPPER SEWING

Select straight stitch.

- Zipper foot is designed to sew close to a raised edge, preventing sewing on the zipper..

- Place the zipper foot in position and attach firmly

- Fold the fabric about 2 cm and place the fabric under the foot

- To sew the left side of the zipper, set the zipper foot on the right side of the needle.

- To sew the right side of the zipperset the zipper foot on the left side of the needle.

Sew as illustrated.

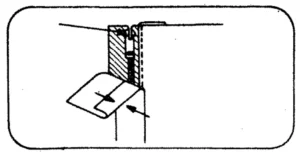

HEMMING

Note: Hemmer foot can be purchased separately.

- Raise the foot and the needle to its highest position. Replace · the foot with hammerer’s foot.

- Fold over the fabric edge by about 3mm and place it under the foot. Secure the folded edge with a few stitches. Take out the workpiece and draw the hem ir: into the hemmer foot by pulling the threads.

- Lower the foot and sew the hem.

- During sewing, fold the fabric to the left a little and allow it to run into the hemmer foot.

- Make sure that the fabric does not move under the right half of the foot. The fabric must be fed into the scroll of the hemmer sufficiently so that the workpiece edge runs freely through the groove under the foot,

Only suitable materials can be used, and some practice may be necessary to achieve the best results.

TWIN NEEDLE

Note: The Twin needle can be purchased separately

Remove the regular needle and insert the twin needle. Thread the BCBO threads through the same path as for normal sewing. Separate threads before the last thread guide above the needle. Insert one thread into the right needle of the twin needle. Insert the other thread into the left needle of the twin needle.

CAUTION: Do not set the stitch width wider than the number 2 setting. Exceeding this will cause breaking of needle to break.

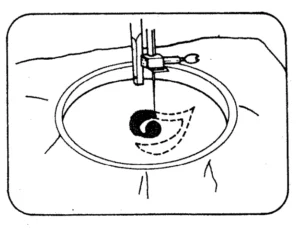

EMBROIDERY

Lower the feed dog and· move the hooped fabric slowly to form the desired effect.

See Page 13 drop feed,

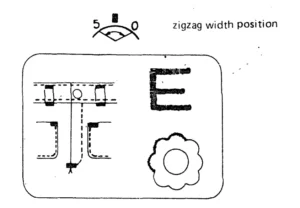

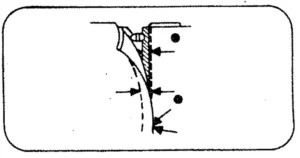

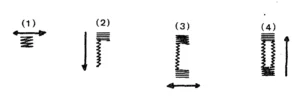

BUTTONHOLE SEWING

- MARK WITH A PENCIL OR CHALK THE EXACT LENGTH OF THE BUTTONHOLE ON THE FABRIC.

- REMOVE THE REGULAR PRESSER FOOT AND ATTACH THE BUTTONHOLE FOOT & PUT THE FABRIC UNDER THE BUTTONHOLE FOOT.

- SET THE STITCH LENGTH KNOB ON ‘O’, ZIGZAG WIDTH KNOB ON ‘5’, AND NEEDLE POSITION KNOB ON CENTER POSITION, THEN SEW 3-5 STITCHES AS FIGURE (1).

- SET STITCH LENGTH ABOUT 0.5, ZIGZAG WIDTH KNOB ABOUT ‘2’ NEEDLE POSITION KNOB ON LEFT POSITION, THEN SEW AS FIGURE (2) UNTIL YOU REACH THE END OF THE MARKING.

- SET ZIGZAG WIDTH KNOB ON ‘5’ THEN SEW 3-5 STITCHES AS FIGURE (3).

- SET THE STITCH LENGTH KNOB ABOUT 0.5, ZIGZAG WIDTH KNOB ON 2, NEEDLE POSITION KNOB ON RIGHT POSITION, PUSH THE “R” BUTTON SEW UNTIL YOU REREACH THE END OF THE MARKING AS FIGURE (4).

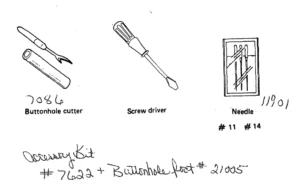

- REMOVE FABRIC FROM THE MACHINE AND OPEN THE BUTTONHOLE WITH A BUTTONHOLE CUTTER OR SEAM CUTTER.

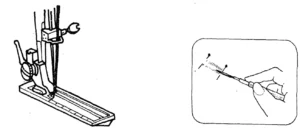

Before sewing the fit buttonhole foot as shown.

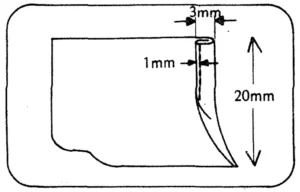

Cut a buttonhole along the centre with the cutter as shown.

Cut a buttonhole along the centre with the cutter as shown.

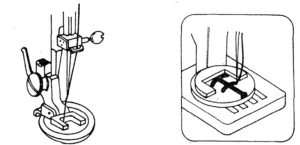

MAINTENANCE (CLEANING AND OILING)

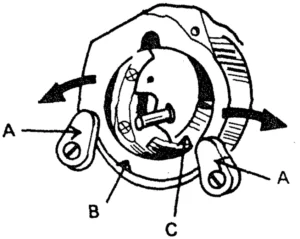

Cleaning shuttle race

- (A) Latch knob

- (B) Shuttle race cover

- (C) Shuttle hook

Open face cover and oil points indicated.

Cleaning feed dog

- Raise Needie to its highest position.

- Take out the bobbin case.

- Turn latch knob A as illustrated.

- Take off the shuttle race cover.

- Take out the shuttle hook.

- Clean and oil the shuttle race and hook, then replace them in the reverse order.

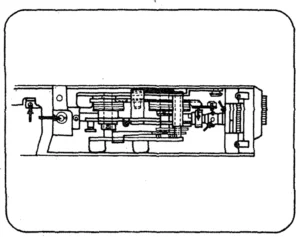

Open the top cover and oil the points indicated.

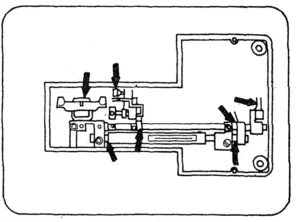

Oil points are indicated on the underside of the bed base.

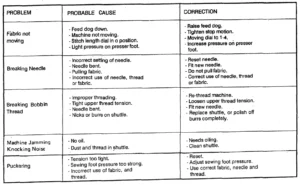

CHECKING, PERFORMANCE, PROBLEMS, WHAT TO DO

Welcome to the wonderful world of sewing with your new White Sewing Machine! Be sure to watch the video and read through the Instruction Book for the basic information you’ll need to get started.

Your new White Sewing Machine offers a variety of stitch capabilities. Instructions for the 18 different stitch functions that are pictured on the box and on the brochure sheet for your White 1418 model follow.

- Straight Stitch with variable length. Set the stitch width dial to 0. Standard straight stitch for joining seams, etc: set stitch length dial to 2-3. Basting stitch: Set the stitch length dial to 4 for a long basting stitch for temporary stitching. This is an easy stitch to pull out later.

- Variable Length Zigzag: The second stitch function pictured is the zigzag stitch, set width 5 and length 3-5. Use this for stitching trims and ric rac in place and for a decorative look.

- Variable Width Zigzag: The third stitch function is a tapered zigzag. Set the length to 3 and the width to O as you begin to sew and increase the width slowly from O to 5 as you sew. This will begin the stitch with a point and taper to a wide zigzag. To sew the taper in the opposite direction, begin at a width of 5 and taper to 0. Use this decoratively or to stitch tt1;pered bartacks.

- Darning and Mending: Set the width diai to 0 and length to 1.5. Stitch across the small tear and push the reverse button to sew back over it. Release the reverse, sew forward over the tear, push reverse to go over the tear again. Continue stitching back and forth over the tear to mend it.

- Buttonhole: Follow the instructions for buttonhole in your Instruction Manual.

- Button Sewing: Consult your Instruction Manual under Button Sewing.

- Corded Buttonholes: Stitch the buttonhole as shown in the Instruction Manual, but before beginning to sew, lower the needle into the fabric and loop a piece of heavy thread or gimp cord around the needle. As the buttonhole columns and bartacks are sewn, catch the cord in the stitching.

- Overcast: Set stitch width to 5. Stitch along the edge of the fabric to overcast or finish the edges to keep them from fraying and to keep them lying flat.

- Hem Stitch: For a Blind Hem on medium and heavy fabrics, fold and press the hem in place. Pin with the pins perpendicular to the hemline. Hold the fabric wrong side up and fold the hem to the right side, but leave about¼” of the wrong side of the hem extending to the right ..You will see: aseeonghihis shis xtension. Set the length to 3.5 and the width to about 4. Sew this zigzag stitch on the extension on the wrong side of the hem with the left swing of the zigzag stitch just catching on the fold of the fabric.

- Gathering: Set stitch length to 4. Sew two rows of this long straight stitch¼” apart and pull the bobbin threads to gather the fabric.

For more manuals by Blogs, visit ManualsLibraryy

White 1418 Portable Sewing Machine- FAQs

Where were White sewing machines originally made?

White sewing machines were manufactured in Cleveland, Ohio, USA, with cabinets crafted by the Kundtz Manufacturing Company in the late 1800s.

Are old White sewing machines valuable?

Yes, some vintage White models are collectible. Their value depends on age, condition, and model type — older, well-maintained machines can attract interest from collectors.

What kind of sewing can I do with the White 1418 machine?

The White 1418 Portable Sewing Machine is designed for basic stitching, buttonholes, hemming, and simple decorative sewing—making it ideal for home use and beginners.

How long does a sewing machine usually last?

With proper maintenance, a sewing machine can last 5 to 25 years. Regular cleaning, oiling, and correct usage can significantly extend its lifespan.

What are common problems with sewing machines?

Typical issues include thread bunching, skipped stitches, or needle breakage. These are often fixed by adjusting thread tension, checking the bobbin, or replacing a worn needle.

Is it better to repair or replace an old sewing machine?

If your machine is high-quality or vintage, repairing it is often worthwhile. However, for basic or cheap models, replacing it may be more cost-effective.

What are the best sewing machine brands today?

Top brands include Singer, Brother, Janome, Bernina, Pfaff, and Usha—known for reliability, stitch quality, and beginner-friendly features.

How much does a good sewing machine cost?

A good home-use sewing machine typically costs between $200 and $400. Advanced or computerized models can be higher, depending on features.

What’s the best type of sewing machine for beginners?

Beginners should start with a mechanical sewing machine that includes basic stitch options, a buttonhole feature, and simple controls like those on the White 1418.