Yeswelder MIG-250PRO Welding Machine

Safety tips

During the welding process, the work may cause some damage to you and other people, so please make some protection. For more details, please kindly read “operator safety manual” accord with accident prevention of manufacturer

Worker must receive professional training before operation!

- Use welding safety products recognized by national safety ministry of supervision.

- Worker must be the special operator with valid certificate of metal welding work.

- During maintenance & repair, please disconnect the line of electricity.

Electric shock: it may cause some injure and even fatal.

- Connect the earth cable according to standard regulation.

- Avoid all contact with live components of the welding circuit, electrodes and wires with bare hands.

- The operator should keep the workpiece & earth insulating from himself/herself.

- Make sure the work place on safe situation.

Smoke-may be bad for people’s health.

- Keep your head out of smoke & welding gas in order to avoid breathing it.

- Keep the working area in good ventilation during welding.

Arc light emission: harmful to people’s eyes & skin.

- To protect your eyes and body, please wear welding helmet, work clothes & gloves.

- People in or near the working area should be protected under welding helmet & other protection equipment.

Fire or explosion hazard may be caused by misoperation.

- Welding fire flame may cause fire, please keep the inflammable substance far from workpiece and keep fire safety.

- Make sure fire extinguisher nearby with a professional fire worker here, who can be skillful with fire extinguisher.

- Don’t weld the closed container.

Don’t use this machine for pipe unfreeze. Hot workpiece may scald your hand.

- Don’t contact the hot workpiece with bare hand.

- During welding continuously for a long time, the welding torch should have some time to release hot.

Magnetic field will affect heart pacemaker.

- The heart pacemaker user will keep far away from welding area before having some inquiry from doctor.

Moving component will cause some damage to people.

- Keep away from moving component, such as fan.

- Keep the panel, back plate, cover and protection equipment fasten on machine

Fault—you should look for some help from professional worker when you face some trouble.

- If you face some trouble on installation and operation, please check the machine according to the operation manual.

- After your reading on operation manual, still can’t understand something or can’t solve the trouble, please should contact with your supplier or our company service center for professional help.

General introduction

MIG PRO-200,MIG-250 PRO-250 CO2/MIG/GASLESS MIG/MMA/LIFT TIG Welding Machines are manufactured based on the internationally advanced inverter technology.The working principle is to invert 50/60Hz alternative current into direct current first. Then the direct current is inverted into high frequency alternative current (20KHz) by IGBT components before it is rectified. Machines in this series have features as follow:

- IGBT Inverter technology, current mode control. Reliable quality and stable performance.

- Closed circuit feedback with constant voltage output. Good resistance to voltage fluctuation. (±15%)

- Electric reactor control, stable welding process with little splash, deep welding pool and beautiful welding seam.

- Slow wire-feeding for arc start and tip ball removing after welding ensure high success rate of arc start.

- Suitable for welding thin and medium metal sheet of above 8mm thickness.

- Small measurement, light weight, easy operation, practical and economical.

- The efficiency of this machine is above 85%. It saves above 30% energy compared with the conventional welding machines.

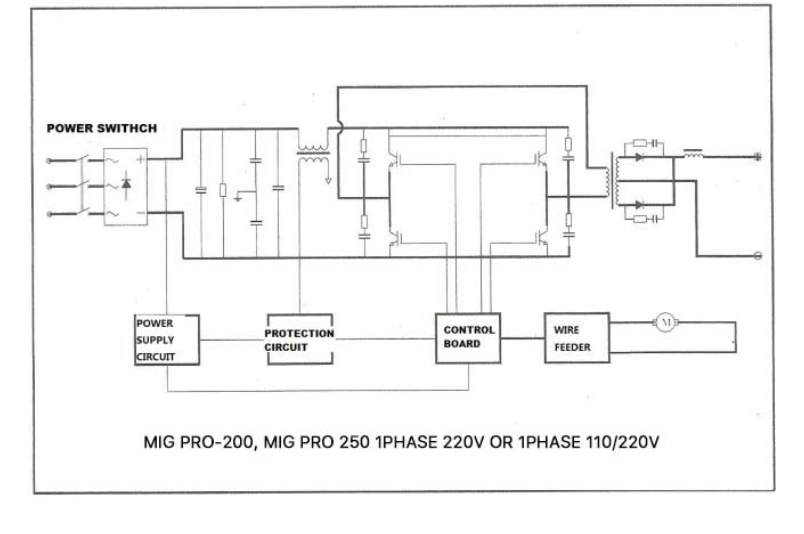

Electrical diagrams

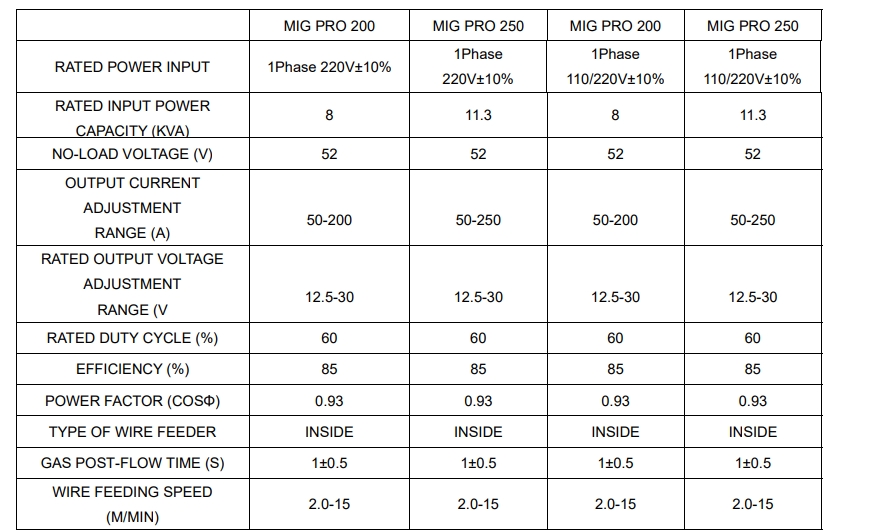

Main Parameter

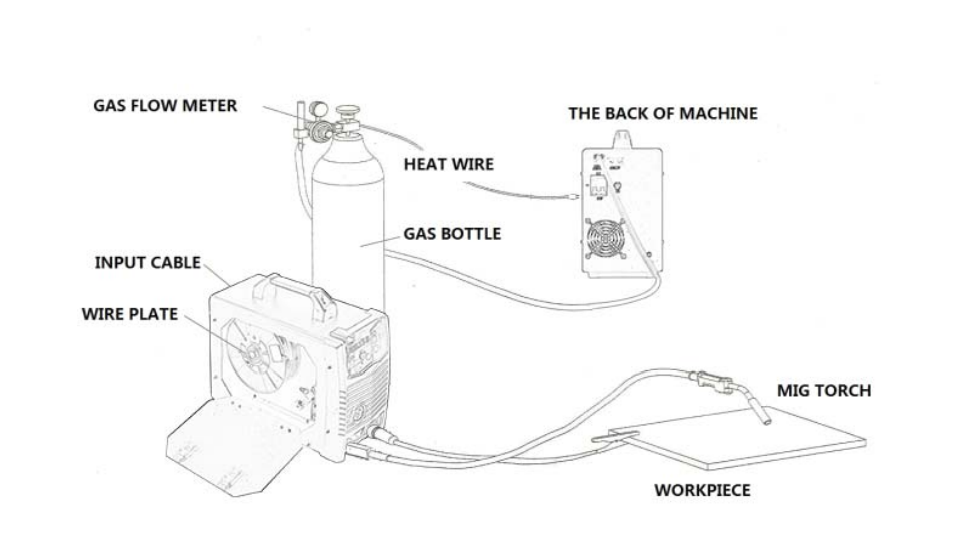

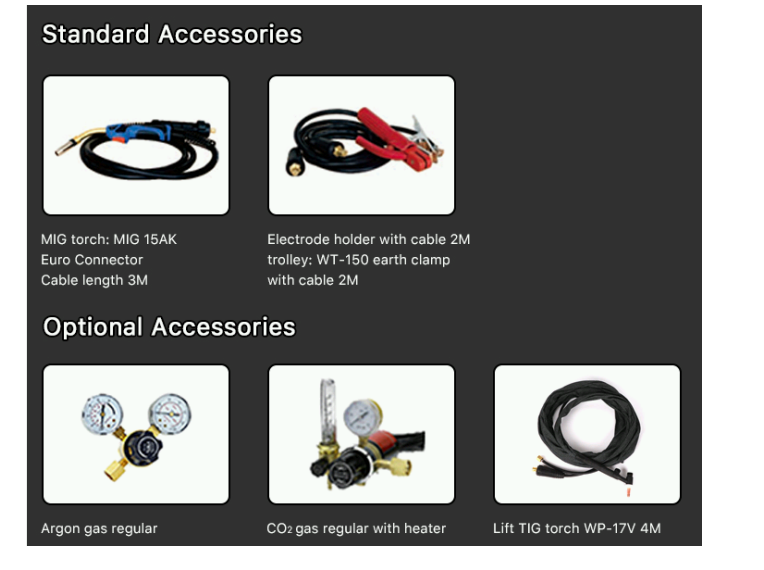

Installation

- Power Input Cable

Each machine is equipped with power input cable. Connect the cable to AC380V power supply.

- Power Output Cable

Connect the CO2 gas bottle firmly with the CO2 inlet on the back of the welding machine by gas-carrying hose. A gas regulator for the CO2 gas bottle is needed.

- Using CO2/MIG,MAG functions, please plug joint into red socket and earth clamp into black socket, plug the welding torch into the on the front panel and screw it tight. Meanwhile, insert the welding wire into the welding torch by hand from built in wire feeder.

- Using Gasless function,connect, please plug joint into black socket and earth clamp into red socket,plug the welding torch into the on the front panel and screw it tight. Meanwhile, insert the welding wire into the welding torch by hand from built in wire feeder.

- Using MMA and TIG LIFT functions,plug electrode holder into red socket and earth clamp into black socket.

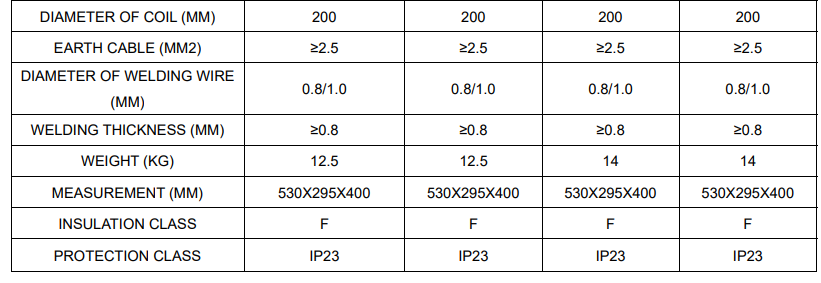

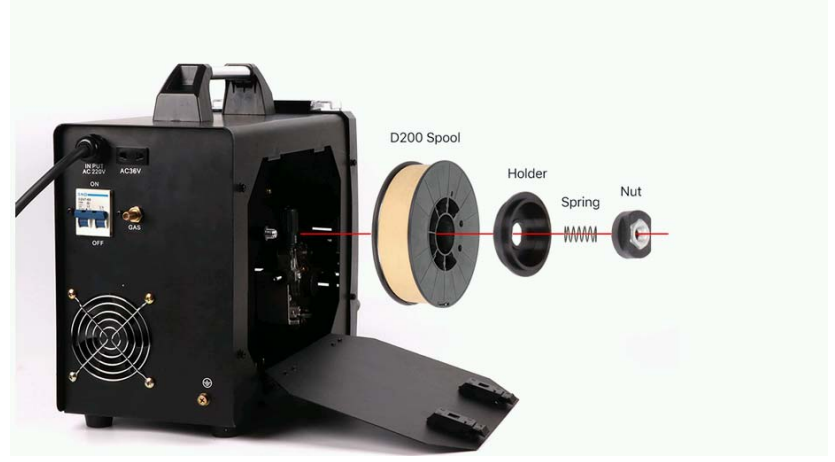

Installation of Wire Spool

WIRE SETUP

- Mount the wire spool with welding wire to the shaft of wire feeder. Lock the wire spool with the spool holder.

- Choose a suitable contact tip according to the size of welding wire.

- Undo the screw of the of wire pressure-wheel and lead the wire into the groove of wire driving wheels via the wire guide tube. Adjust the pressure wheel to ensure no slippage of wire occurs. But too much pressure would cause deformation of welding wire and affect the wire feeding speed.

- Release the welding wire roll by counter clock-wise direction. The head part of the welding wire is always inserted into the fixing bore on the rim of wire spool to ensure avoid the looseness of wire. So please just cut the bent head part off while using in order to avoid wire stuck.

- Choose the correct track of the wire feeding groove by the welding wire diameter.

- Press the “Inching” button to lead the wire out of the welding torch.

WELDING PERFORMING

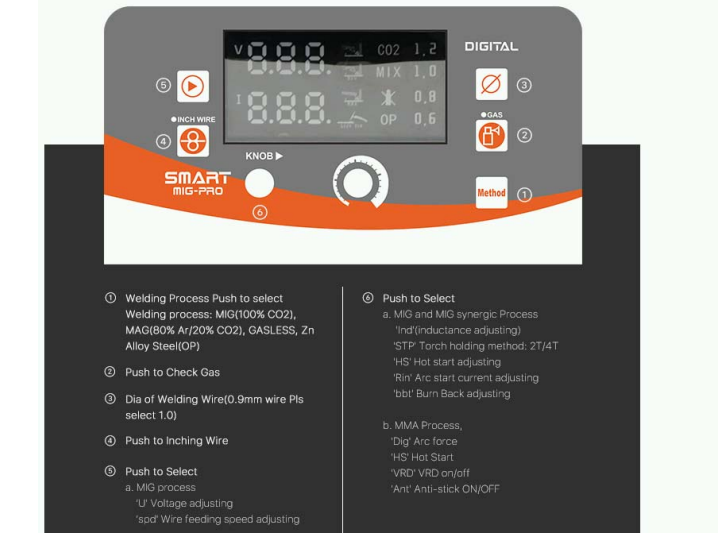

Operation

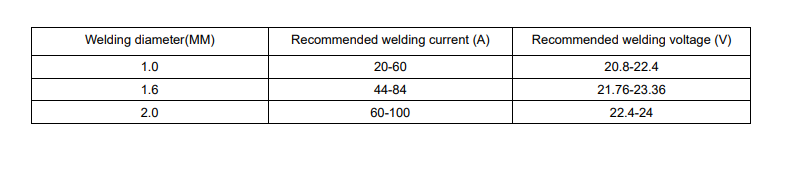

Setup of the Welding Current

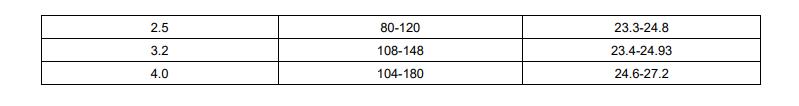

The welding current and arc voltage have a direct influence on the stability, quality and efficiency of welding. So a good coordination of the welding current and arc voltage is required for a high quality welding. It is decided by the diameter of welding wire, mode of droplet transfer and requirement of welding efficiency. Regarding the setup of current and voltage for general welding, please consult the form below. Regarding the different welding requirement, please refer to the “Zoom Table of Welding Parameter”.

Welding Parameter List. (For Low-carbon Steel)

Setup of Welding Speed

The welding speed affects the welding quality and efficiency. Higher welding speed means less gas-protection, accelerated cooling speed, lower flexibility and forming of welding seam. Lower welding speed is likely to cause burning through of the workpiece and a puffy welding seam. In the actual production, please keep the welding speed less than 30m/h.

Setup of Dry Extension ofWeldingWire

A longer dry extension of welding wire means a deeper penetration, a faster melting of welding wire and a higher production efficiency. But an excessive length of dry extension is likely to cause burnout of wire and splash of droplet. So a 10 times length of the welding wire diameter is always chosen in the actual welding operation.

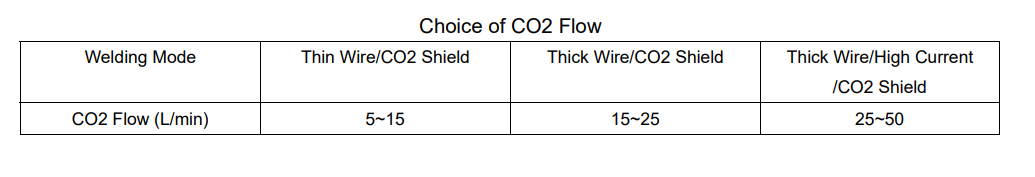

Setup of CO2 Flow

The CO2 flow is rated to the gas protection effect. Besides, the gas protection of inside fillet welding is better than that of outside fillet welding. So a lower gas flow shall be chosen. For specific digits, please consult the form below.

Attention

Attention

Work Environment.

- The environment should be dry and the air humidity didn’t exceed 90%.

- Temperature should be from -10℃ to 40℃.

- Avoid welding under rain or hot sunshine, don’t let water or rain into machine.

- Don’t work under dust area or aggressive fume.

- Avoid using the machine under strong air flow.

Safe tips.

The machine is equipped with overvoltage, overcurrent and overheat protection device. If the voltage, output current and temperature exceed the standard, the machine will stop working. Besides, overusing the machine based one xceeded voltage, the machine will be damaged, so please kindly note as below:

Ensure GoodAiriness.

During the working, the machine will generate high temperature and it needs help from fan to cool the machine. So users please make sure the ventilation inlet is not stuck or covered. Meanwhile, keep the objects around the machine in a distance of no less than 0.3m. Keeping airiness helps to lower the temperature more quickly and ensures a longer service life of the machine.

Current Overloading Prohibited

Close attention should be paid to the permissible loading current(the available duty cycle) to ensure the welding current being under maximum permissible current. Current overloading shortens service life of a machine greatly, or even damages the machine.

Voltage Overloading Prohibited

For the power supply voltage, please refer to the “Main Parameter Table”. Under normal circumstances, the auto-compensation circuit in the machine will help to keep the welding current within permissible range. Voltage overload damages the machine, so preventive measures are needed.

- Earth cable connects to the ground. There is a mark near the earth screw on the back panel. Before using the machine, please choose a wire (cross sectional area above 6 mm2) to connect the earth screw to ground to avoid electricity leakage accident and release static electricity.

- No overload of the standard rated duty cycle. When it overloads the standard, the machine will stop working due to overheating inside of machine. After stopping and resting for some time, the machine can be started to work again.

Maintenance

- Below operation should be done by a professional operator with electrical engineering & safe knowledge and ability qualify certificate. Before opening the machine, please make sure the machine input power wire is unconnected to the power supply.

- Check junction circuit inside of welding machine on time, make sure all the junctions are right, stable connectors (especially on plug connector or component). If anyone is rust or loose, please get rid of the rust or oxide film with sandpaper, reconnect it and make the connection fastened up.

- Don’t be close to electron component (such as fan) inside of machine by hand, hair, or other tools when the machine is energized.

- Get rid of the dust with dry compressed clean air. If the machine works under dense smoke & polluted air, please get rid of the dust every day. The compressed pressure should be in the workable level to avoid component damage.

- Try best to keep the water & water vapor from inside the machine. If the water come into inside of machine, please kindly dry the machine immediately. Then, please test insulation situation of welding machine (including each connection or between connections and the shell). Firstly, if ok, please continue to work.

- Check all the covers of the welding cable in general. If any wear out, please bind up or change it.

- Please keep the welding machine in its original package in a dry place during long time no using.

Fault and repair

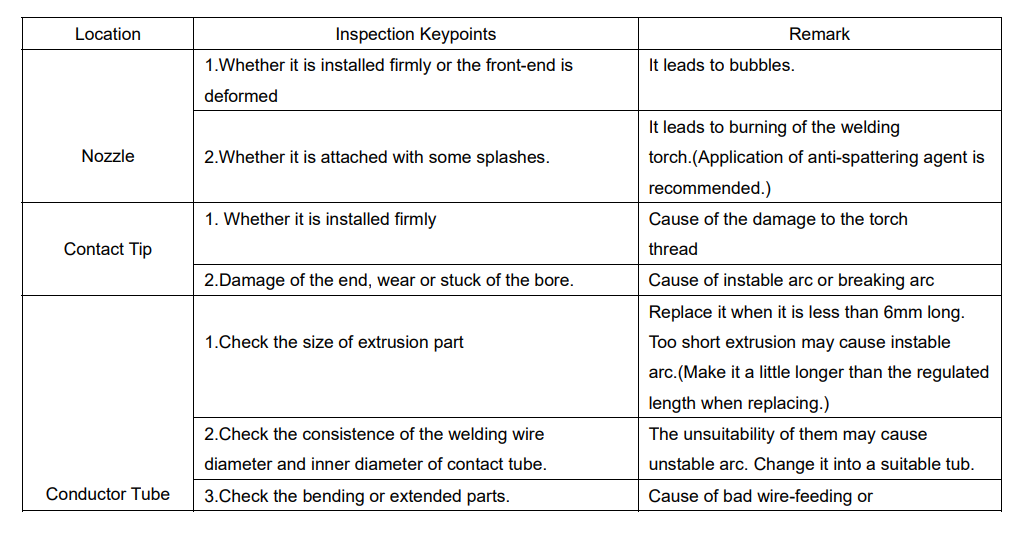

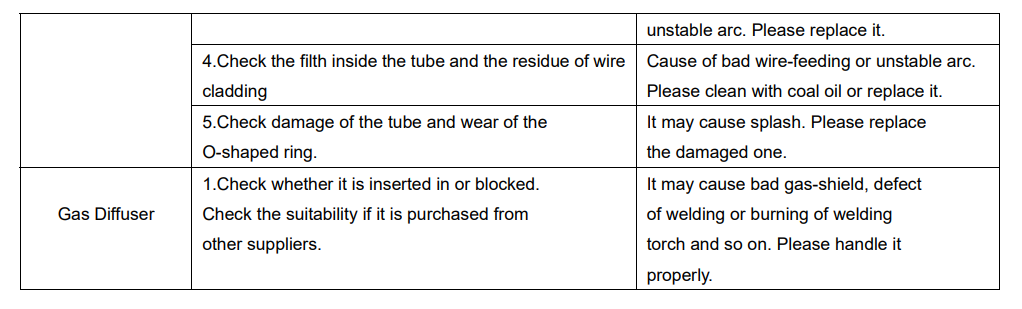

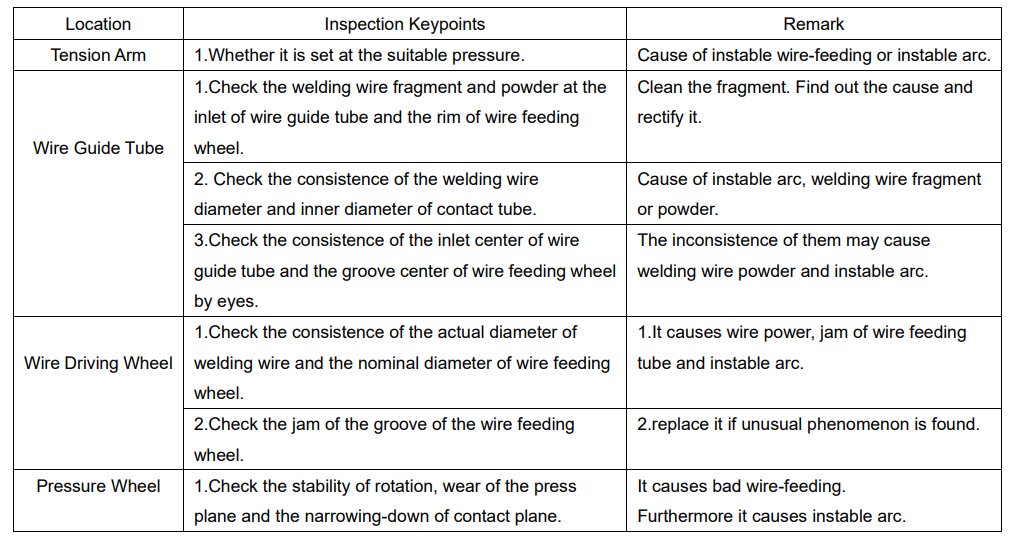

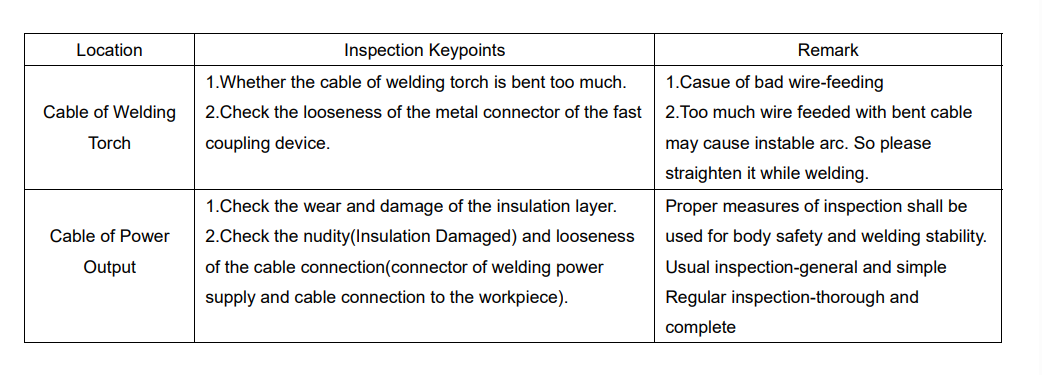

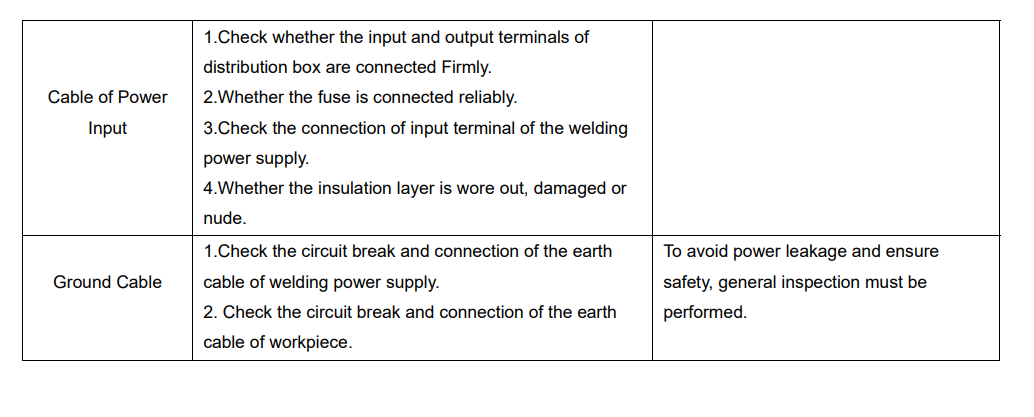

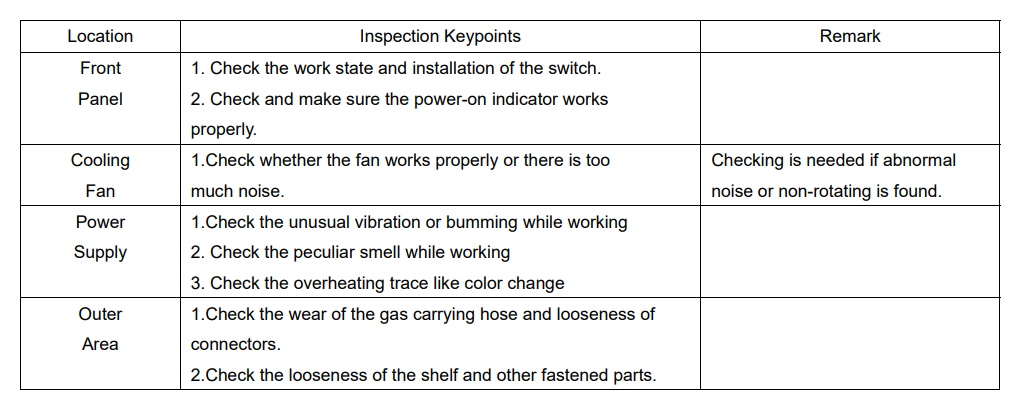

In order to optimize the machine’s function and ensure a safe working condition, maintenance and troubleshooting is critical. When performing maintenance and troubleshooting, please focus on and check the following parts and points: welding torch, wear of spare parts in the wire feeding device, deformation and gas hole. Clean the dust of some parts or replace it if necessary. To keep the original function of the machine, please purchase the genuine spare parts only from our company

Welding Power Supply

Welding Torch

Welding Torch

Wire Feeder

Power Output Cable

For more manuals by Yeswelder, visit ManualsLibraryy

Yeswelder MIG-250PRO Welding Machine-FAQs

How do I set up the MIG-250PRO?

Wear safety gear, attach the ground clamp, open gas valve (12-20 CFH), set voltage/wire speed, and maintain 3/8″ wire stick-out.

What’s the duty cycle?

60% at 250A (6 minutes welding per 10-minute cycle).

What thickness can it weld?

½-inch steel, ¼-inch aluminum (spool gun recommended for aluminum).

Does it do TIG and Stick?

Yes (MIG, Flux-Cored, Stick, and DC TIG with a torch).

What wire should I use?

Steel: ER70S-6

Aluminum: ER4043 (with spool gun)

Stainless: ER308L

Gasless: E71T-GS flux-core

What gas for MIG?

Steel: 75% Argon + 25% CO₂

Aluminum: 100% Argon

Can it weld aluminum?

Yes, with 100% argon & spool gun (ER4043/ER5356 wire).

2T vs. 4T mode?

2T: Hold trigger to weld.

4T: Tap to start, tap to stop (better for long welds).

Voltage & wire speed settings?

Thin metal (18G): 14-16V, 150-200 IPM

1/8″ steel: 18-20V, 300-400 IPM

1/4″ steel: 22-24V, 400-500 IPM

Why is my weld porous?

Low gas flow, dirty metal, or wind. Use 15-20 CFH and clean surfaces.

Welding Torch

Welding Torch