Weldpro TIGACDC200GD Welder

SAFETY WARNING

DANGER: Please observe the following rules to avoid serious accidents

- Never use the equipment for purposes other than welding.

- Follow related regulations regarding the characteristics of the power source, choice of place, usage of high-pressure gas, storage, configuration, safe-keeping of the workpiece after welding, and disposal of waste etc.

- Non-essential personnel shall not enter the welding area.

- Persons using a pacemaker are not allowed near the welding machine or welding area without a doctor’s permission. The magnetism created by energizing the welding machine may harm the pacemaker.

- The installation, operation, inspection, and maintenance of the equipment must be carried out by authorized personnel.

- For your safety, you must understand the contents of the user’s manual.

DANGER: Please observe the following rules to avoid an electric shock

- Keep away from any electrical parts.

- The machine and workpiece shall be grounded by authorized personnel.

- Cut off the power before installation or inspection, and restart it 5 minutes after finishing that activity. The capacitor is a rechargeable device. Please ensure it has no voltage before starting again, even if the power source is cut off.

- Never use wire with an inadequate wire gauge, damaged insulation sleeve, or exposed conductor.

- Do ensure the proper isolation of wire connections.

- Never use the device when the enclosure is removed.

- Never use broken or wet insulation gloves.

- Welding screens must be used when working in the overhead position.

- Check and maintain the equipment regularly. Do not use the equipment until the faulty parts are fixed.

- Turn off the power when not in use.

- Follow the related national and local standards and regulations when using the AC welding machine in confined spaces or overhead positions.

DANGER: Please observe the following instructions to avoid fire, explosions, etc.

- Remove combustible materials from the welding area.

- Keep away from any combustible materials while welding.

- After welding, keep the hot workpiece away from flammable gases.

- Remove all combustible materials when welding on a patio, on the ground, or on a wall.

- The work lead of the base metal should be as close to the welding place as possible.

- Never weld installations with gas pipes or airtight valves.

- Keep a fire extinguisher close to the welding area to prevent fire.

WARNING: The gases and fumes are hazardous to health. Please wear personal protective equipment according to regulations.

- Wear exhaust equipment and respiratory protective equipment to prevent gas poisoning or choking.

- Use the suggested exhaust ventilation system and respiratory protective equipment to prevent injuries or poisoning by gas or dust.

- To prevent oxygen deficiency, air out the gas-filled space full of CO2 and argon on the bottom, when operating in trunks, boilers, cabins, etc.

- Request a supervisor’s inspection when operating in confined spaces. Air the room and wear respiratory protective equipment.

- Never operate in degreasing, washing, or spraying spaces.

- Use respiratory protective equipment while welding armored steel, as this produces poisonous dust and gases.

PRODUCT DESCRIPTION

This welder is an inverter-based machine that utilizes the most advanced inverter technology. IGBT circuits, along with PWM technology along with the greatly reduced size and weight, enable this welder to not only be more efficient by 30%, but also, as a

result of the electronic circuitry, enables this welding machine to afford the user far more and better range of settings for each specific weld. The ACDCTIG200 also has a 40% duty cycle at full amperage, which, explained another way, allows for a full four

minutes of uninterrupted continuous welding at full amperage within ten minutes. Far more capable than any user would dream of attempting. The ACDCTIG200 is capable of welding with either AC or DC. This allows the user to choose DC welding for

carbon steel, stainless steel, copper, and many other metals, while also being equipped with the ability to switch over to AC welding used in welding aluminum and aluminum alloys. In addition to its advanced TIG welding functions, the ACDCTIG200 is also a very good MMA / Stick welder. This AC/DC TIG welder adopts our company’s exclusive High Frequency technology as well as a pure square wave output, excellent arc force, and a wide range of balance control for aluminum cleaning. This AC/DC TIG welder also offers a feature not always found in this price range. That is a completely dedicated foot control

with no interim current control on the foot pedal. This design is a much sought-after feature of advanced welders who greatly dislike the idea of inadvertently changing amperage settings while readjusting the foot pedal with their feet while changing their

welding positions. This is no longer a concern with the Weldpro ACDCTIG200 since all amperage control settings are made from the console on the machine’s face. Thank you for purchasing our product. We are sure you will soon realize the great value and quality that went into the design of this welder, as well as all of the advanced features and functions.

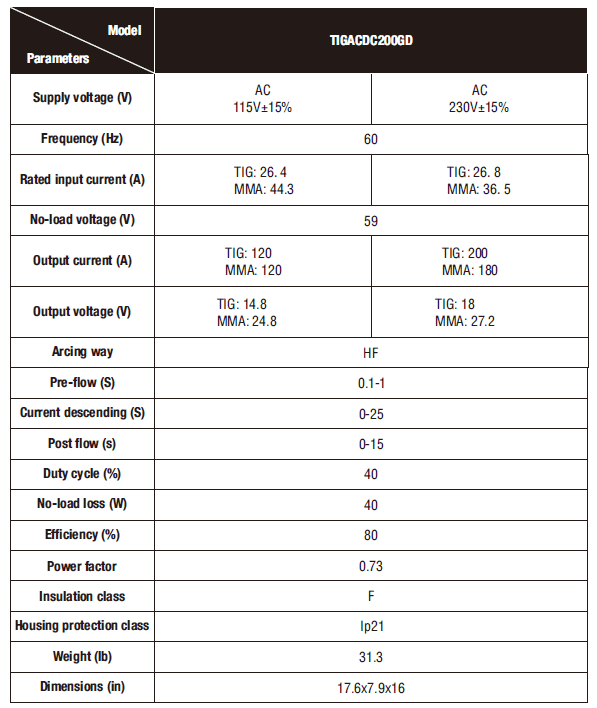

TECHNICAL PARAMETERS

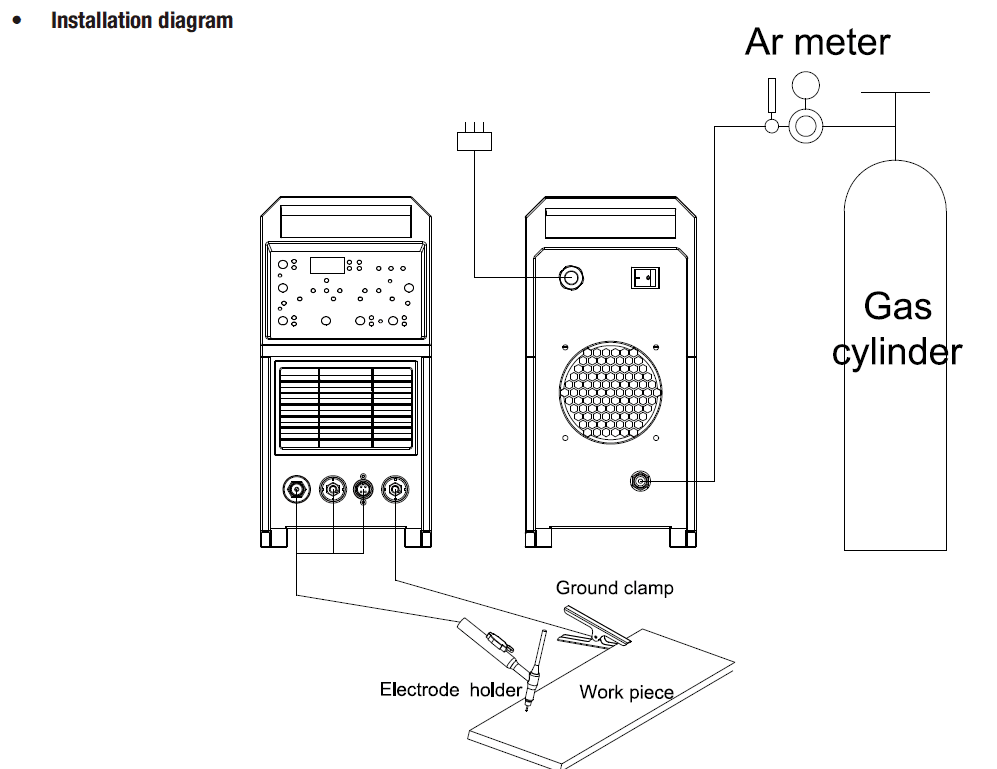

INSTALLATION

The component setup of this welding machine is a simple, straightforward process. This welder is fitted with a Power Voltage A compensator that takes into consideration a + / – 15% of the rated voltage for this machine. However, it is most important to be sure your power supply to this welding is of the proper voltage and is in good condition with clean connections, proper wiring, and the correct circuit breakers. It is strongly suggested that if longer leads are used for grounding, that larger wire gauge is used to reduce the possibility of line loss due to resistance. Be sure when you are setting up your welding machine that the vents and fans are not obstructed and are allowed to flow air freely.

The required Argon gas cylinder should only be connected to the welder through a proper regulator/flowmeter. The working range of the gas flow (depending on the work being done) is approximately 20 cubic feet per hour (CFH) or 9.5 litres per minute (LPM). All press-on connection hoses should be further secured with a clamp to prevent inadvertent disconnects. Snug connections to both the regulator, argon tank, and welding machine. Over-tightening any of these connections can damage the equipment.

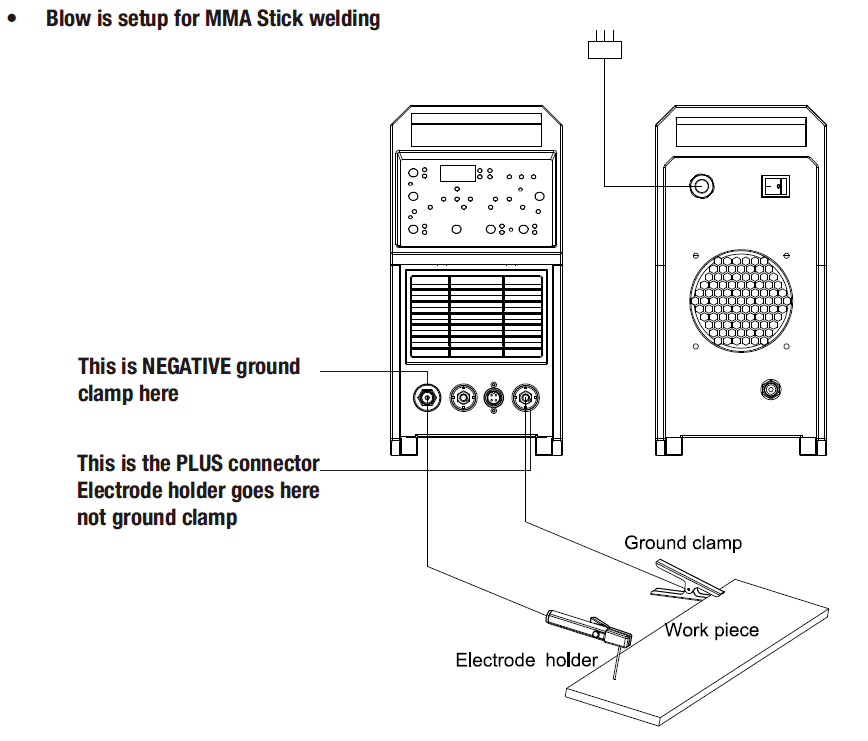

The tungsten electrode needs to be properly shaped to a point. When doing so, it is recommended that you use a dedicated grinding wheel. Preferably, a diamond-coated wheel is inexpensive and effective. Also note that while grinding the tungsten to a point, the grinding marks should run longitudinally with the length of the tungsten rather than across the width of the tungsten to avoid arc wander while the arc is finding ground as it welds. Connecting the electrode and work (also called ground) cables correctly to your welder. Let’s take a moment here to clarify what can be a confusing subject to new users. Generically, when welding, the user has a choice of polarity connections. What is correct for one type of welding may be wrong for another type of welding. So, let’s explain what is happening and which way to connect for which type of welding. Electric current flows from negative to positive. When TIG welding, the polarity settings should be Straight Polarity Electrode Negative! That means that the Work clamp (aka ground) is connected to the Plus (+) Dinse connector, and not the negative, as some consider normal. Of course with the TIG function, the TIG electrode cable is screwed into its dedicated threaded receptacle, but rest assured this receptacle is the negative connector. When connecting the TIG Torch, a gentle, snug connection is all that is needed. DO NOT OVER-TIGHTEN THE BRASS CONNECTOR. When using the ACDCTIG200 in the MMA or Stick mode, the connection to the front of the welding machine is just the

opposite! Stick or MMA welding is done with Reverse Polarity Electrode Positive! That means when you are going to stick weld with the ACDCTIG200, you must connect your electrode holder ( the one that holds your welding rod) to the Positive Dinse Connector, and you connect your work clamp (aka ground) to the Negative Dinse Connector. Connecting the foot pedal or the TIG trigger button to the face of the welder for TIG Mode. When using the foot pedal, which is the most common way to TIG weld, connect the foot pedal to the push pin connector on the front of the welder. NOTE: Be sure the 2T function is the active setting on the face of the welder when using the foot pedal. Connecting the torch trigger switch to the welder requires disconnecting the foot pedal plug and instead plugging in the small round push connector plug, which is attached to the TIG Torch cable in its place. When using the TIG Trigger, you can choose between 2T and 4T functions. While the 2T function is the most common choice for TIG Trigger button use, the 4T may be an option you wish to explore.

Simply put, the 2T function requires 2 Trigger button movements to start and end a weld. 1 push to start the weld, and 2 release to end the weld. The 4T function requires 4 Trigger button movements to start and end a weld. 1 push to start the weld, 2 release to maintain the weld and continue, 3 push the trigger button once again as the first step to ending the weld, and finally 4, release the button to stop the weld. After completing the above step,,s you are ready to weld. Be sure to follow all safety procedures. One last note here. When opening your Argon tank, the valve on the Argon tank is designed to seat and seal the Argon from leaking from the tank in the fully closed or fully open positions. Do not merely crack open the Argon tank valve. Doing so may result in losing valuable

and costly Argon gas to the outside air for no good reason, so set your Argon valve full open to use and full closed for storage.

OPERATION

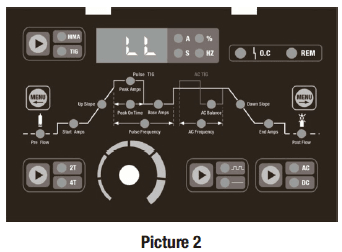

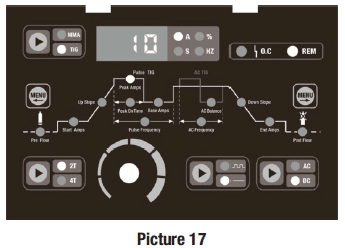

The ACDCTIG200 welder front panel is designed to be intuitive and easy to use while offering a wide variety of advanced function settings. As a result of the many options the user has at his or her disposal, the Main Control Knob is designed to be a “multi function” knob capable of setting many parameters. At the top of the front panel and to the immediate right side of the digital numeric display, you will find four (4) LED lights, each of which designates the current mode that the welder is in. Regardless of which mode the welder is currently in, the “Multi-Function” knob controls all the settings of those modes. The four (4) LED lights represent the following values for adjustment.

From left to right and from top to bottom, those modes are…. A= Amps, %= percent, S= seconds, HZ= Hertz. As you touch the menu buttons on either side of the welder’s face, you will toggle along the graph line from left to right or right to left among the various options. When doing so, the LED mode lights will change and light up to represent the current numeric display value settings.

Below is a brief description of what each TIG function is used for.

Broken up into three horizontal rows, the top row from left to right represents 1. Welding mode MMA ( which is stick welding) or TIG which is Tungsten Inert Gas welding mode. Next is the digital display panel explained above. Next, T.O.C.O.C light, which designates an over-temperature condition that requires waiting and possibly rebooting the system. Lastly, the REM remote light lights with the use of the foot pedal. Along the middle/center row of functions, you will find a selection of all the advanced features of the TIGACDC200GD machine. At each end of the center, you will find a menu button. Depending on how far along the line of options you are, you can click either menu button to proceed left to right or right to left. Some of the functions are not necessary when using the foot pedal controller because the user has complete control of some of these options with that foot pedal. These functions are as follows and will be explained in further detail later. START AMPS, UP SLOPE, DOWN SLOPE, END AMPS. When using the foot pedal, it is recommended to give the choice to lower these values to

ze, to, since the user can use the foot pedal rheostat to control all of those settings in real time while welding.

- The preflow is the time in seconds that Argon gas will flow before the TIG is initiated. The purpose of preflow is to ensure the area to be welded is protected from the outside environment and air before actual welding begins. This prevents

contamination of the weld zone. When using the foot pedal, a tap of the pedal before positioning yourself for welding will help purge the Argon line if the welder has been idle for any period, and if the TIG torch is directed at the work area, it will shield the area from the environment before welding. When using the TIG Torch trigger, the user cannot directly modulate current as they can with the foot pedal, although techniques are available to simulate this,,s given some practice. They will also be discussed. This is where the Preflow, Start Amp, and Up Slope features come in very handy. When initiating the well,d often, if not always, the user want to gently “ramp up” to full current rather than shock the work instantly. The Start Amp feature allows the user to set the amperage at the initial start of the arc. The Up Slope function allows the user to set the period in seconds it will take the current to reach full amperage. The “Full Amperage” will be the Peak Amps. Conversely, when the weld is being terminated ( while using the TIG Trigger Button), the Down Slope, End Amps, and Post Flow functions are able to be set to finish the weld. The TIGACDC200GD welder has a very adjustable Pulse feature, which can be adjusted multiple ways to offer an almost infinite range of variables.

Pulse is just as it implies, a pulsing of amperage power while welding. Pulse Frequency is the number of times per second that amperage pulses will occur. The range is 0.5 to 200 HZ, or times per second. Peak time on allows the user to set the time within that second that the amperage will be at the dialed-in peak setting..

(highest amperage). Base amps are the measure of what the lesser amperage will be during the pulse, and are represented in a percentage of whatever the user has chosen for the peak amps.

AC Welding

When welding carbon steel using the TIG function, the welder’s polarity is set to Straight Polarity Electrode Negative. The current flows in one direction only. Doing so directs the heat / current from the tungsten into the metal to be welded. This polarity helps keep the TIG tungsten cool and heats the work. Welding Aluminum presents an entirely different set of problems that welding with DC Straight Polarity does not do well with. Aluminum forms a very thin layer/skin, over itself called aluminum oxide. Interestingly, aluminum oxide melts at about 3500 degrees F., while the actual aluminum itself we want to weld, melts at a much lower 1500 degrees F. So, attempting to weld with DC flowing from the tungsten to the work metal, the aluminum melts UNDER the oxide coating layer without actually melting the aluminum oxide. This results in what looks like trying to weld through a glob of mud, or even a mercury-like

consistency covering. This does not make for a good weld. The solution, while a bit complicated, provides excellent results. Choosing DC Reverse Polarity will create a current flow from the metal work back up into the TIG Torch tungsten, bursting through the aluminum oxide layer very well, but … we cannot choose to weld with DC Reverse Polarity where the current flows from the metal work into the Tungsten, because we would quickly melt our TIG Torch, tungsten, and collets. The solution is to weld using AC or Alternating Current. Currently, it switches back and forth between DC Electrode Negative and DC Electrode Positive, back and forth many times per second. While it is the DC Electrode Positive cycle that cleans up the aluminum oxide, it is also the cycle that can melt away our tungsten, so we have to carefully meter the amount of time our welding current spends in the DC Electrode Positive phase. The AC Balance feature allows for the adjustment of time during the alternating current cycle that the current spends in the electrode positive. The least amount of time in this cycle will provide the best cooling of our TIG tungsten. This is why cleaning the aluminum to be welded before welding is so important. It allows us to keep our current in the straight polarity electrode negative cycle longer. An initial setting of 30 % to 35% is recommended to help keep the tungsten cool. AC Frequency setting is a setting that allows for the adjustment of how many times per second your chosen AC balance setting cycles. It is adjustable from 0.5 to 200 HZ (times per second). The lower horizontal line of controls is first your choice of 2T or 4 T. (Always select 2T when using the foot peda.l) Second, the main control knob. Icanto varies by 1 increment or, if pushed in, 10 increments at a time. Next is the toggle between pulse and normal ( no pulse), and lastly is the toggle between AC and DC.

Below is an illustrated explanation of the functions

- Panel Layout

2. Operation interface specification

2. Operation interface specification

Picture 2 shows the digital display meter reads “LL” when the machine starts working.

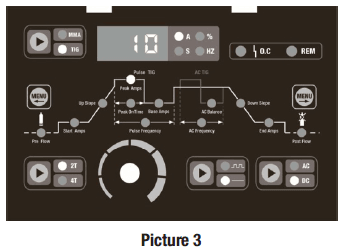

The picture 3 shows when under TIG mode, the Peak Amps indicator light on, adjust the parameter knob, meter reads 5-200A adjustable, press the Move Left/Right Selector

Menu Button to choose other parameter settings.

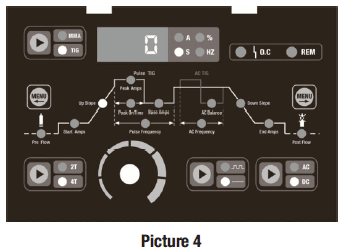

The picture 4 shows when under 4T mode, press the Move Left Selector Menu Button to Up Slope indicator light on, adjust the parameter knob, the meter reads 0-10s adjustable.

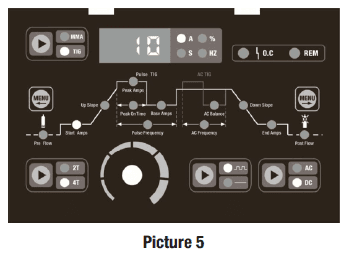

The picture 5 shows press the Move Left Selector Menu Button to Start Amps indicator light on, adjust the parameter knob, the meter reads 5-200A adjustable.

The picture 6 shows when under pulse mode, press the Move Right Selector Menu Button to Peak On Time indicator light on, adjust the parameter knob, the meter reads 10-90% adjustabl.e

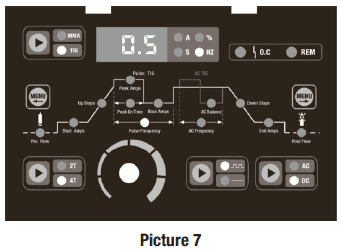

The picture 7 shows press the Move Right Selector Menu Button to Pulse Frequency indicator light on, adjust the parameter knob, the meter reads 0.5-200 HZ adjustab.le.

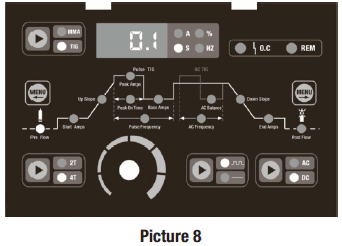

The picture 8 shows press the Move Left Selector Menu Button to Pre flow indicator light on, adjust the parameter knob, the meter reads 0.1-1S adjustable.

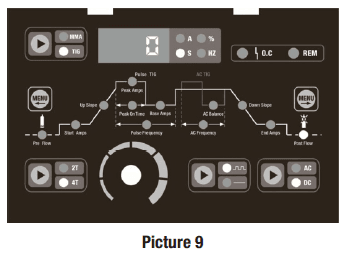

The picture 9 shows press the Move Right Selector Menu Button to Post flow indicator light on, adjust the parameter knob, the meter reads 0-15S adjustable.

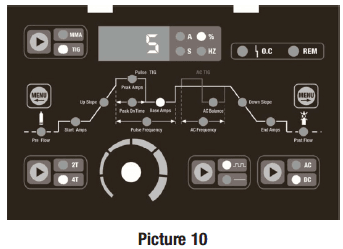

The picture 10 shows press the Move Right Selector Menu Button to Base Amps indicator light on, adjust the parameter knob, the meter reads 5-95% adjustable.

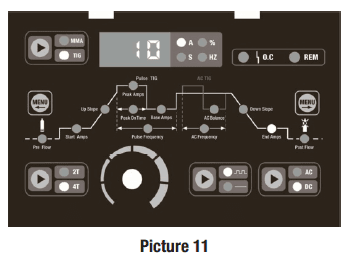

The picture 11 shows press the Move Right Selector Menu Button to End Amps indicator light on, adjust the parameter knob, the meter reads 5-200A adjustable.

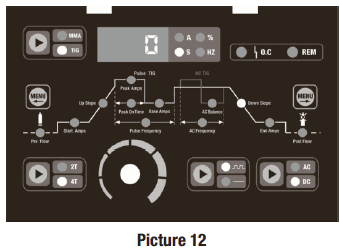

The picture 12 shows press the Move Right Selector Menu Button to Down Slope indicator light on, adjust the parameter knob, the meter reads 0-25S adjustable.

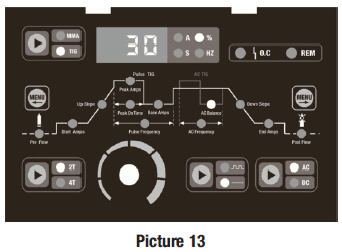

The picture 13 shows when choose under AC mode, press the Move Right Selector Menu Button to AC balance indicator light on, adjust the parameter knob, the meter reads 30-70% adjustable.

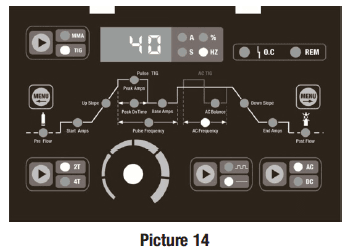

The picture 14 shows when choose under AC mode, press the Move Right Selector Menu Button to AC Frequency indicator light on, adjust the parameter knob, the meter reads 40-200HZ adjustable.

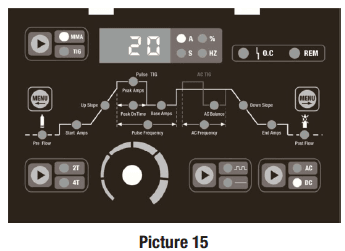

The picture 15 shows when choose under MMA mode, adjust the parameter knob, the meter reads 20-180A adjustable, only AC/DC mode can be selected, other buttons can’t be usedPicturere 16 shows that when the temperature is too high or abnormal, the digital display shows “Err”, the abnormal light O.C. lights up, this time no output, will have to wait until the

temperature or restart the machine to return to normal.

Picture 17 shows that in TIG mode, when connecting the foot pedal to the machine, the REM indicator is on, and the machine is converted to REM mode automatically. At this time: Start Amps, Peak Amps, End Amps these three current parameters are controlled by the foot pedal, other parameters are controlled by the knob on the front panel.

INSTRUCTION NOTES

- Operation environment

- Welding operations should be carried out in a relatively dry environment with air humidity usually less than 90%.

- Ambient temperature should be kept between 10 °C and ~40 °C.

- Welding in the sun or rain should be avoided, and water or rainwater should never seep into the welder’s interior.

- Welding in a dusty area or under a corrosive gas environment should be avoided.

- Gas protection welding operation in an environment with strong air flow should be avoided.

- Safety

In this welder, over-voltage, over-current, and overheat protection circuits have been installed beforehand. When the grid voltage, output current,t, and machine temperature surpass the set standards, the machine will stop automatically. But excessive use (for example, when the voltage is too high) can still lead to the breakdown of the welder. So you have to pay attention to the following items:- Good ventilation! This machine is a small type of welder. In operation, a high working current flows in, and natural ventilation is unable to meet the welder’s requirement for cooling. So a fan is fitted to effectively cool the welder to keep it working smoothly. Operators should make sure that the vent is not covered or plugged, the distance of the welder from its surrounding objects is not less than 0.3 m, and good ventilation is maintained at all times. All these are very important for the better operation of the welder and the longer service life of the welder.

- No overload! Operators should bear in mind that the maximum permissible load current (relative to the selected load duration factor) should be observed at any time, and welding current should never surpass the maximum permissible load current. Over-current will shorten the service life of the welder remarkably and even burn it down.

- No over-voltage! Power voltage is shown in the main performance parameter table. In general, the voltage auto-compensation circuit in the welder will ensure the welding current remains within the permissible range. If the power voltage surpasses the permissible value, the welder will be damaged. Operators should fully know this and adopt the corresponding preventive measures.

- Behind each welder there is a grounding screw with the grounding mark. Before the operation, the shell of the welder should be grounded reliably by a cable wire with a sectional area bigger than 6 mm2 so as to release static electricity or prevent any accident due to leakage.

- If the welding machine exceeds the standard load duration factor in operation, it may suddenly go into a protective state and stop work, which indicates it has exceeded the standard load duration factor. Excessive heating triggers the temperature control switch and makes the welding machine stop operating. Under such circumstances, you needn’t turn off the power so that the cooling fan may work continuously for cooling. When the temperature drops to the standard range, welding may be restarted.

MAINTENANCE AND CHECK TROUBLE

- Maintenance:

- Dust should be removed with dry and clean compressed air regularly. If the welder is used in a heavily polluted environment with dense smoke and polluted air, dust must be removed from the welder each month.

- The pressure of compressed air should be reasonable so that damage is not done to small elements in the welder.

- Regularly check the connection of the electric circuit in the welder and make sure the circuit is connected properly and the joint is secured (especially the inserted joint or element). If the cases of rusting or loosening are found, the rust layer or oxidized film should be removed with abrasive paper, and then the joint should be connected again and tightened firmly.

- Entry of water or steam into the interior of the welder should be avoided. If this condition occurs, the welder should

undergo drying treatment. Then the welder is measured for insulation by a megohmmeter (including the area between connecting points and the areas between the connecting points and the shell). Welding can go on only when evidence shows no abnormality. - If the welder is not to be used for a long time, it should be replaced in the original package and kept in a dry environment.

- Check Fault

Phenomena enumerated here may have something to do with the parts, gas, environmental factors, and power supply you use, and efforts should be made to improve the environment to avoid the occurrence of such cases.

A Black welding spot

This shows the welding spot is oxidized without being protected effectively, and you can make the following

inspection :

- Make sure that the valve of the argon cylinder has been opened with sufficient pressure. As a rule, if the pressure within the cylinder is lower than 0.5MPa, then it is necessary to refill the cylinder.

- Check if the argon flow meter is turned on with sufficient flow. You can select different flow rates in light of varying welding current, but too small a flow may lead to inadequate gas stiffness and thus failure to cover all the welded spots. We suggest argon flow should never be lower than 3l/min, no matter how weak the current will be.

- The easiest way to check gas delivery is to touch the nozzle of the welding torch to see whether the gas passage of the welding torch is blocked.

- Poor sealing of the gas passage or lower gas purity will also give rise to welding quality trouble.

- Strong air flow in the environment may also lead to deterioration of welding quality.

B. Difficulty in arc starting with easy arc breaking:

- Make sure that the tungsten electrode in use is of good quality, as the idischargeability of an inferior tungsten electrode may fail the requirement;

- A tungsten electrode without sharpening treatment is also unable to start an arc and leads to an unstable arc.

C Output current can’t reach the rated value:

Deviation of power voltage from the rated value will lead to nonconformity of the current value with the set value. When the power voltage is lower than the rated value, the maximum output current of the welder may also be lower than the rated value.

D. Unstable current in the operation of the welder:

This may be attributed to the following factors:

- Change in grid voltage;

- Interference from the power grid or other power equipment.

E Severely burned tungsten needle

The duty cycle is adjusted too large, causing emission from the workpiece to the tungsten electron for too long, resulting in severe heat of the tungsten needles.

The oxide film can’t be torn when welding aluminum:

- The welding gear is selected wrong.

- The duty cycle is adjusted too small.

- The secondary inverter has field pipe damage.

G The abnormal pilot lamp is on:

- The light is on when the welder works abnormally, please turn off the power switch and then reboot the machine, it can continue to use if it returns to nor. a l,

- If the light is on repeatedly, please refer to the professional or the manufacturer for repair.

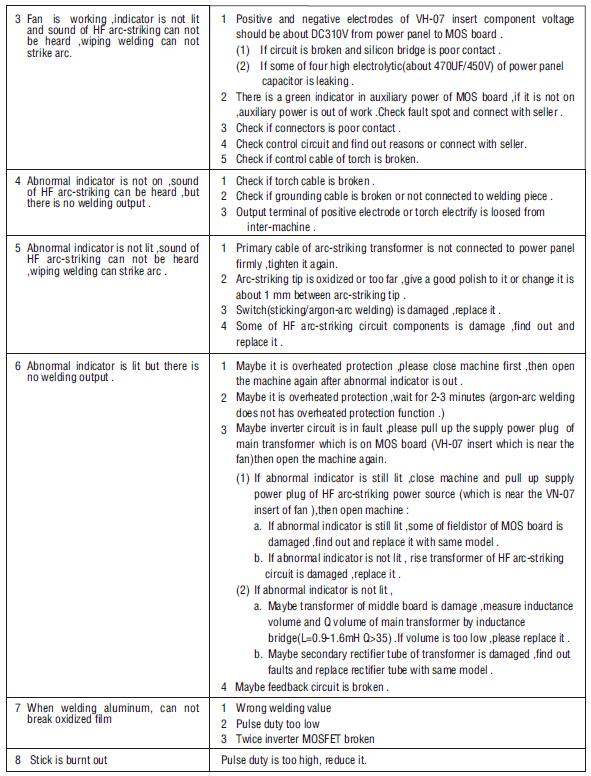

TROUBLESHOOTING

FOR MORE MANUALS BY WELDPRO, VISIT MANUALSLIBRARYY

Weldpro TIGACDC200GD Welder-FAQs

What power supply do Weldpro TIGACDC200GD welders require?

This welder supports dual voltage input and can run on both 120V (115V) and 240V (230V) power sources with automatic voltage sensing.

What types of welding can the Weldpro TIGACDC200GD perform?

It performs both AC/DC TIG welding and AC/DC Stick welding (SMAW), making it versatile for many welding tasks.

What is the amperage range of this welder?

TIG welding output ranges from 5 to 200 amps DC and 10 to 200 amps AC.

Stick welding output ranges from 10 to 180 amps.

What are the duty cycle specifications?

Duty cycle is 40% at 200 amps for DC TIG and 60% at 200 amps for AC TIG, meaning the welder can operate continuously for 4 minutes out of every 10 before needing to cool down.

What features help control the welds?

The welder has a fully digital menu allowing precise adjustment of welding parameters including:

Pre-flow and post-flow gas settings

Start and end amps

Upslope and downslope time

AC balance and frequency

Pulse frequency and timing for both AC and DC welding.

Does the TIGACDC200GD offer pulse welding?

Yes, it includes a pulse function that controls heat input, ideal for welding thin or delicate materials and reducing distortion.

What is included in the Weldpro TIGACDC200GD package?

Typically includes:

KT26 TIG torch or ERGO17 TIG torch (depending on model)

Foot pedal control

Electrode holder and ground clamp

Flow meter and gas hose

Power adapter for 115/230V

Consumables kit.

What materials can the Weldpro TIGACDC200GD weld?

Suitable for welding steel, stainless steel, aluminum, copper, chromoly, brass, and bronze, which covers most common metals.

How reliable is the Weldpro TIGACDC200GD?

The machine uses advanced IGBT inverter technology for efficient and stable welding performance.

Comes with a 3-year factory warranty for peace of mind