Kenmore 15343 Mechanical Sewing Machine

IMPORTANT SAFETY INSTRUCTIONS

This machine is designed and manufactured for household use only.

When using an electrical appliance, basic safety precautions should always be followed, including the following: Read all instructions before using this appliance.

DANGER: To reduce the risk of electric shock:

- An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the electric outlet immediately after using and before cleaning.

- Always unplug before replacing a sewing machine bulb. Replace the bulb with the same type rated 15 watts.

WARNING — To reduce the risk of burns, fire, electric shock, or injury to persons.

- Do not allow it to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.

- Use this appliance only for its intended use as described in this owner’s manual. Use only attachments recommended by the manufacturer as contained in this owner’s manual.

- Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return this sewing machine to the nearest Sears store or service center for examination, repair, electrical, or mechanical adjustment.

- Never operate the appliance with any air opening blocked. Keep the ventilation openings of this sewing machine and foot controller free from accumulation of lint, dust, and loose cloth.

- Never drop or insert any object into any opening.

- Do not use outdoors.

- Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

- To disconnect, turn all controls to the off (“0”) position, then remove the plug from the outlet.

- Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

- Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

- Always use the proper needle plate. The wrong plate can cause the needle to break.

- Do not use bent needles.

- Do not pull or push fabric while stitching. It may deflect the needle, causing it to break.

- Switch this sewing machine off (“0″) when making any adjustment in the needle area, such as threading the needle, changing the needle. Threading the bobbin, changing the presser foot, and the like.

- Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

NOTE: Sewing machine design and specifications are subject to change without prior notice.

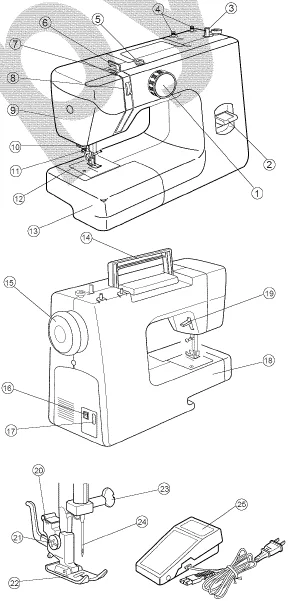

NAMES OF PARTS

Cabinets and Sewing Machine Tote Bag (RSOS #97611)

Sewing Machine cabinets and Tote bags are available through the RSOS (Retail Special Order System) catalog at your nearest Sears retail store (U.S.A. only)

Names of Parts

- Stitch pattern selector

- Reverse stitch control

- Bobbin winder spindle

- Spool pins

- Bobbin winding tension disc.

- Upper needle thread guide

- Thread take-up lever

- Thread tension dial

- Face cover

- Thread cutter

- Needle threader (Mode! 15343 exclusive)

- Needle plate

- Extension table (Accessory box)

- Carrying handle

- Handwheel

- Power switch

- Machine socket

- Free-arm

- Presser foot lifter

- Presser foot holder

- Set screw

- Presser foot

- Needle clamp screw

- Needle

- Foot control

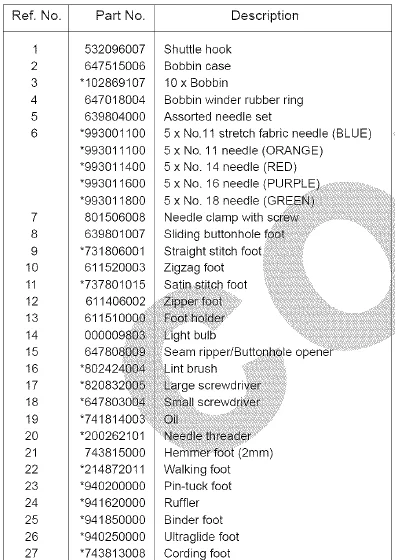

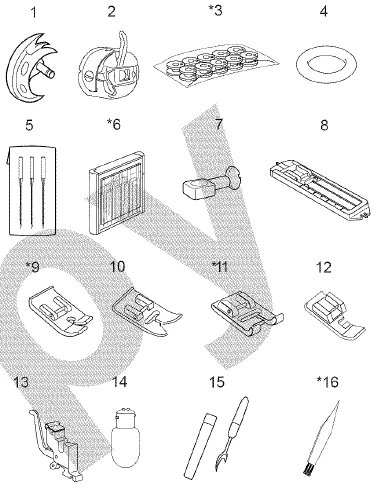

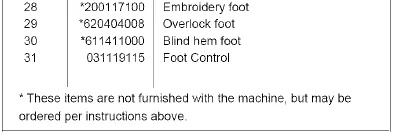

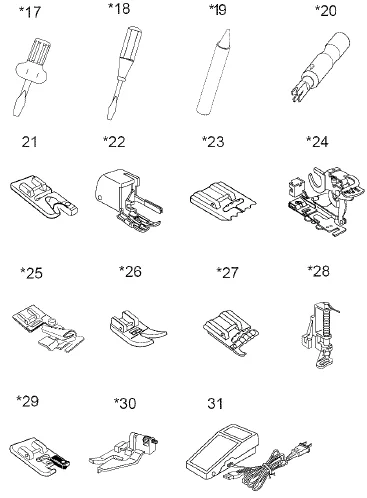

Available Accessories and Attachments

To order parts and accessories listed below, call 1-800-4-MY-HOME® (1-800-469-4663), call any time, day or night.

When ordering parts and accessories, provide the following information:

- Part Number

- Part Name

- Model Number of Machine

To order additional parts not listed above for a do-it-yourself repair.

- Using the Internet, type in “www3.sears.com” to reach the Sears Parts Website.

- Follow the prompts. And enter your sewing machine ‘model number. You can find your sewing machine ‘model number on the back of your machine, on the Nameplate. Enter the first eight digits of this number, followed by an asterisk (example: 385.15243/15343″)

GETTING READY TO SEW

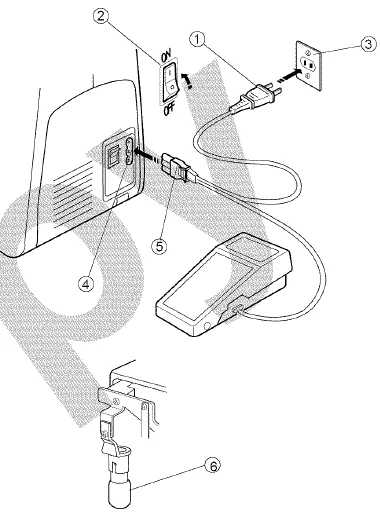

Connecting Machine to Power Supply

- Power supply plug

- Power switch

- Outlet

- Machine socket

- Machine plug

- Sewing light

Before connecting the power cord, make sure the voltage and frequency shown on the machine conform to your electrical power.

- Turn off the power switch (2).

- Insert the machine plug (5) into the machine socket (4).

- Insert the power supply plug (1) into the outlet (3).

- Turn the power switch (2) to activate the power and sewing light (6).

Before Using Your Sewing Machine

Before using your sewing machine for the first time, place a waste fabric under the presser foot and run the machine with thread for a few minutes. Wipe away any of that may appear.

For Your Safety

- While in operation, always keep your eyes on the sewing area. Do not touch any moving parts, such as the thread take-up lever, handwheel, or needle.

- Always turn off the power switch and unplug from the power supply.

- When leaving the machine unattended

- When attaching or removing any parts

- When cleaning the machine

- Do not place anything on the foot control when not sewing.

Polarized Plug

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of an electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way. Foot Controller Model YC-482J or TJC-150 is used with Sewing Machine Model 385.15243/15343

Controlling Sewing Speed

Sewing speed can be varied by the foot control.

The harder you press on the foot control, the faster the machine runs.

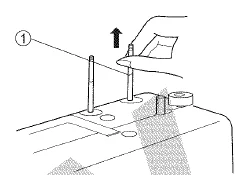

Setting Spool Pins

- Spool pin

The spool pins are used for holding the spools of thread when feeding the thread to the machine.

To use, pull up the spool pins. Push down for storage.

Presser Foot Lifter

- Presser foot lifter

- Normal up position

- Highest position

The presser foot lifter raises and lowers the presser foot.

You can raise it about 1/4″ (0.6 cm) higher than the normal up position for easy removal of the presser foot, or to help place heavy fabric under the foot.

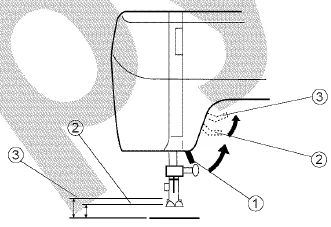

Thread Cutter

- Thread cutter

You do not need a pair of scissors to cut threads after sewing. Simply use the built-in thread cutter.

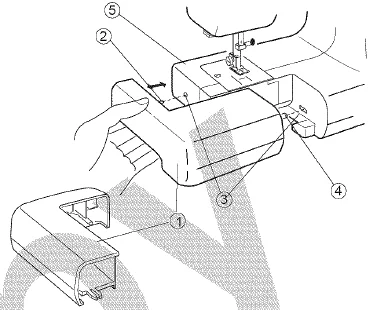

Extension Table

Detaching the table

Pull the table away from the machine, as illustrated, for “free-arm” sewing of cuffs and sleeves. The extension table can be used as an accessory box.

Attaching the table

Push the extension table until it snaps into the machine.

- Extension table

- Pin

- Holes

- Tab

- Free-arm

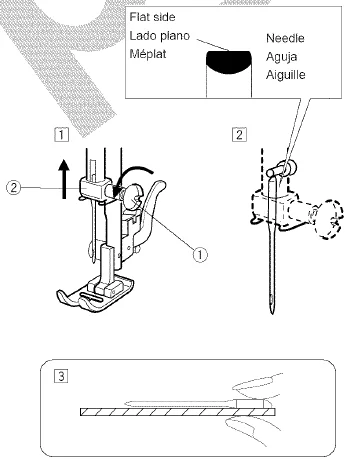

Changing Needle

- Needle clamp screw

- Needle clamp

- Turn off the power switch. Raise the needle to its highest position by turning the handwheel counterclockwise, toward you, and lowering the presser foot. Loosen the needle clamp screw (1) by turning it counterclockwise. Remove the needle from the needle clamp (2).

- Insert a new needle into the needle clamp (2) with the flat side to the rear. When inserting the needle into the needle clamp (2), push it up as far as it goes. Tighten the needle clamp screw (1) firmly by turning it clockwise.

- To see if the needle is good, place the flat side of the needle onto something flat (e.,g needle plate or glass). The gap between the needle and the flat surface should be consistent. Never use a bent or blunt needle. A damaged needle can cause permanent snags or runs in knits, fine silks, and silk-like fabrics.

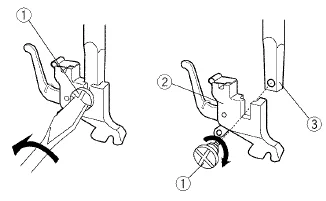

To Remove and Attach the Foot Holder

- Set screw

- Foot holder

- Presser bar

To remove

Remove the set screw (1)by turning it counterclockwise with a screwdriver.

To attach

Match the hole in the foot holder (2) with the threaded hole in the presser bar (3). Fit the set screw (1) into the hole. Tighten the screw (1) by turning it clockwise with a screwdriver.

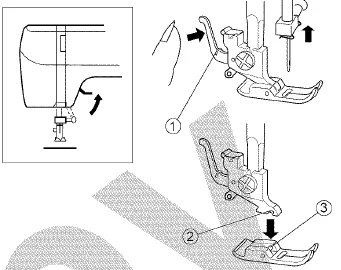

Changing Presser Foot

- Lever

- Groove

- Pin

To remove

Turn the handwheel toward you to raise the needle to its highest position. Raise the presser foot. Press the lever (1)on the back of the foot holder. The presser foot will drop off.

To attach

Place the presser foot so that the pin (3) on the foot lines up directly below the groove (2) of the foot holder. Lower the foot holder to lock the foot in place.

Presser Foot Types

Zigzag foot

Use this foot for both straight and zigzag stitching.

Sliding buttonhole foot

Use this foot for manual buttonhole making. It is marked to help you measure a buttonhole accurately.

Zipper foot

The edge of the foot guides the zipper and keeps the seam straight.

Hemmer foot

This special foot is for sewing a rolled hem. The curl of the foot helps to form a hem at a constant width.

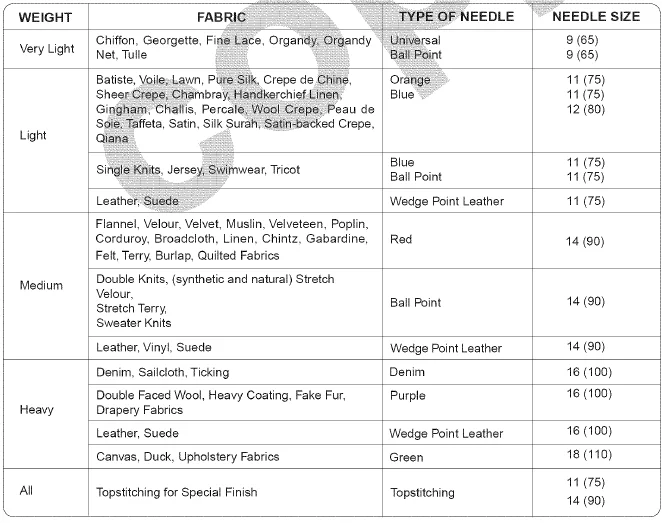

Selecting Needle and Fabric

For general sewing, use needle sizes 11 or 14. A fine thread and needle should be used for sewing lightweight fabrics, so the fabric will not be marred. Heavy fabrics require a needle large enough to pierce the fabric without fraying the needle thread.

In the needle set, there is one of each size 11, 14, 16, and 18, and a blue needle. Use the blue needle to eliminate skipped stitches when sewing knits and synthetic fabrics.

Special needles should be used on certain fabrics. A denim needle with a sharp tip effectively pierces dense fabrics such as denim and canvas. For topstitching, a special topstitching needle with a larger eye accommodates heavier-weight thread. Leather needles punch small holes in leather and suede, allowing the thread to follow through the hole.

Check your needles frequently for rough or blunt tips. Snags and runs in knits, fine silks, and silk-like fabrics are permanent and are often caused by damaged needles.

Always purchase a good quality thread. It should be strong, smooth, and consistent in thickness.

Bobbin Winding

Removing the bobbin case

Remove the extension table from the machine by pulling it to the left. Open the shuttle cover by pulling down the embossed part on the left of the cover.

Raise the needle to its highest position by rotating the handwheel toward you.

- Shuttle cover

- Bobbin case

To remove the bobbin case from the shuttle, pull open the latch of the bobbin case. Pull the bobbin case straight out of the shuttle.

Bobbin winding

- Release the clutch by pulling out the handwheel. This will stop the needle from moving while you wind the bobbin.

- Draw thread from the spool.

- Guide the thread around the thread guide.

- Thread through the hole in the bobbin from the inside to the outside.

- Put the bobbin on the bobbin winder spindle.

- Push the bobbin to the right.

- With the free end of the thread held in your hand, depress the foot control. Stop the machine when the bobbin has made a few turns, and cut the thread close to the hole in the bobbin.

- Depress the foot control again. When the bobbin is fully wound, it stops automatically. Return the bobbin winder to its original position by moving the spindle to the left, and cut the thread.

- Push in the handwheel to engage the clutch. The machine does not function until the clutch is engaged.

NOTE:

The position of the bobbin winder stopper is adjustable depending on the required amount of thread on the bobbin (i.e., 1/2 full or full). Use a screwdriver and loosen the screw one turn or less. Do not take the screw all the way out. Adjust the position of the bobbin winder stopper. Retighten the screw.

Inserting bobbin

- Place a bobbin in the bobbin case, making sure the thread feeds clockwise from the bobbin.

- Draw the thread through the slot of the case.

- Continue to draw the thread under the tension spring (1) and through the opening. Pull out about 4 (10 cm) of thread.

- Holding the latch open, position the bobbin case into the shuttle, and then release the latch.

- The case should lock into place when the latch is released.

Threading the Machine

Threading the machine

- Raise the thread take-up lever to its highest position by turning the handwheel counterclockwise.

- Raise the presser foot lifter.

- Place a spool on the spool pin, with thread coming off.

- Draw the end of the thread around the upper thread guide.

- While holding the thread near the spool, draw the end of the thread down around the check spring holder.

- Firmly draw the thread up and from right to left over the take-up lever, then down into the take-up lever eye.

- Slide the thread behind the needle bar thread guide on the left.

- Thread the needle from front to back.

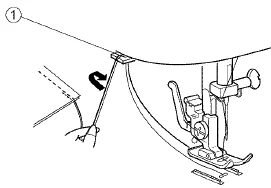

NeedleThreader (Model15343exclusive)

- Raise the needle to its highest position. Pull down the needle threader knob as far as it will go.

- Turn the knob in the direction of the arrow in the illustration, then insert the hook into the needle eye. Lead the thread around the Guide and under the Hook.

- Turn the knob in the direction of the arrow in the illustration, drawing the thread loop through the needle.

- Pull the thread through the needle eye.

The needle threader can be used with a #11 to #16 needle or a blue tipped needle. Thread size 50 to 90 should also work well.

For more Manuals by Kenmore, visit ManualsLibraryy

Kenmore 15343 Mechanical Sewing Machine-FAQs

How old is the Kenmore sewing machine brand?

Kenmore sewing machines date back to 1913. Over the decades, models like the Kenmore Rotary Deluxe (1939–1949) and others have become sewing classics.

Who manufactures Kenmore sewing machines?

Kenmore sewing machines were made by several companies for Sears, including Maruzen (now Jaguar), Janome, and other trusted manufacturers from Japan and Taiwan.

Are Kenmore sewing machines still being made?

No, new Kenmore sewing machines are no longer produced. However, many older models are still widely used and appreciated for their reliability.

Can I still buy parts for a Kenmore sewing machine?

Yes. Replacement parts for Kenmore machines are still available through online retailers like Sewing Parts Online and A-1 Appliance Parts.

How long does a sewing machine usually last?

A well-maintained mechanical sewing machine can last anywhere from 10 to 25 years—or even longer with regular cleaning and oiling.

Is the Kenmore 385 model a low shank machine?

Yes. The Kenmore 385 series uses a low-shank design, meaning most low-shank presser feet and accessories will fit perfectly.

How can I tell if my sewing machine is high shank or low shank?

Measure from the screw that holds the presser foot to the base plate. If it’s about ½ inch, it’s low shank; if it’s about 1 inch, it’s high shank.

What are common problems with sewing machines?

Typical issues include thread bunching, skipped stitches, broken needles, and tension problems. These can usually be fixed with cleaning or adjusting tension settings.

Is it better to repair an old sewing machine or buy a new one?

If your machine is high-quality and parts are available, repairing is often more cost-effective than replacing, especially for vintage Kenmore models.