Nordson TruFlow Flex Adhesive Dispensing Controller

Description

System Overview

This manual describes the installation, operation, and setup of the TruFlow Flex HS controller.

The controller is used in a material delivery system to control and/or monitor adhesive consumption and add-on weights by providing in-line measurement and reporting of adhesive-per-piece data for better process control. The controller includes the following capabilities:

- Monitor and record adhesive output by individual part, either on a time/ day/shift or current total basis.

- Preset control parameters, warnings, and alarms to stop the line if dispensing deviates beyond upper or lower dispensing limits.

- Improve the volumetric flow of adhesive during ramp-up and steady state operation by using the closed-loop encoder feedback.

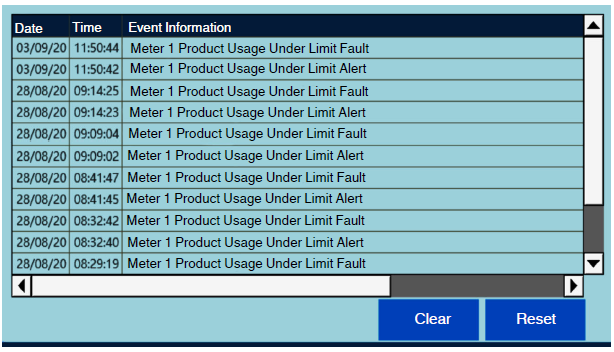

See Figure 2 below for an overview of how the controller is integrated in a typical adhesive delivery system.

Figure 2: Controller in a typical adhesive delivery system

- Melter

- Controller

- Hose from the melter to the meter

- Meter

- Hose from the meter to the applicator

- Applicator

- Transmitter box

![]()

CAUTION! Do not connect the TruFlow Flex Controller directly to the TruFlow meter. Only connect the TruFlow Flex Controller to the Transmitter Box as shown in Figure 2. Connecting the TruFlow Flex Controller directly to the meter will cause meter damage.

Configurations

There are several different configuration options:

- Controller with 100 Ohm platinum RTD

- Controller with 120 Ohm nickel RTD

- Controller with adhesive heating capability

- Controller without adhesive heating capability

- Controller with built-in HMI

- Controller with remote HMI

Intended Use

The controller is specifically designed for use:

- With compatible equipment manufactured by Nordson Corporation

- In non-explosive environments

The controller is intended to be incorporated into machinery or assemblies by an integrator. The equipment must not be placed into use in a member state of the European Union until the parent machinery or assemblies have been declared by the integrator to conform with the applicable directives of the European Commission.

Limitations of Use

Use the controller only for the purpose for which it is designed. Do not use the controller:

- With any material that creates a health or safety hazard when heated

- In environments that require the system to be cleaned using a water wash or spray

Product Description

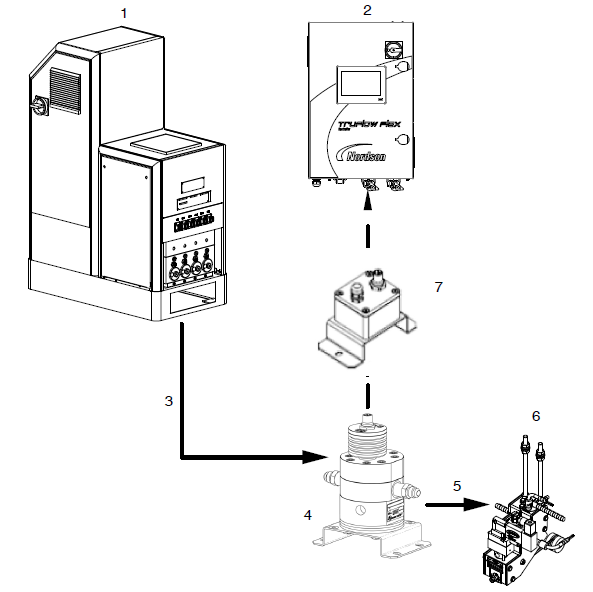

The controller is used in conjunction with the Nordson hot melt melter, hose, and applicator to create a material application system, as shown in Figure 2 on page 15. The external components are shown in Figure 3 below, and the internal components are shown in Figure 4 on page 18 and Figure 5 on page 19.

External Components

Figure 3: External components of the controller with heating

- Fan

- Main Switch

- Touch screen panel

- Air-in filter

- Heater connector with Ni120 RTD (Heating units only)

- Flow meter connector

- I/O connector

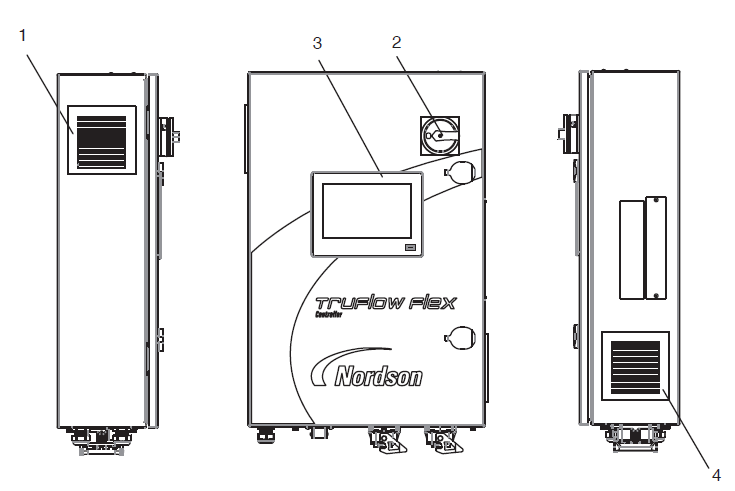

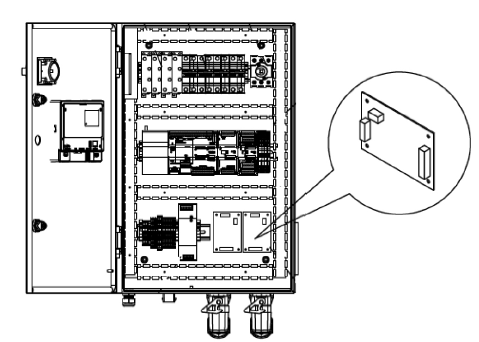

Internal Components

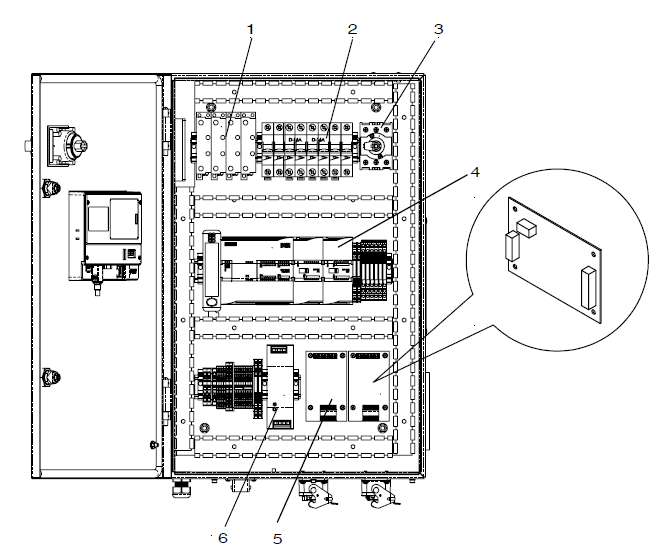

Figure 4: Internal components of the controller with heating zones

- Solid-state relay

- Circuit breaker

- Main Switch

- PLC

- Meter board

- DC power supply

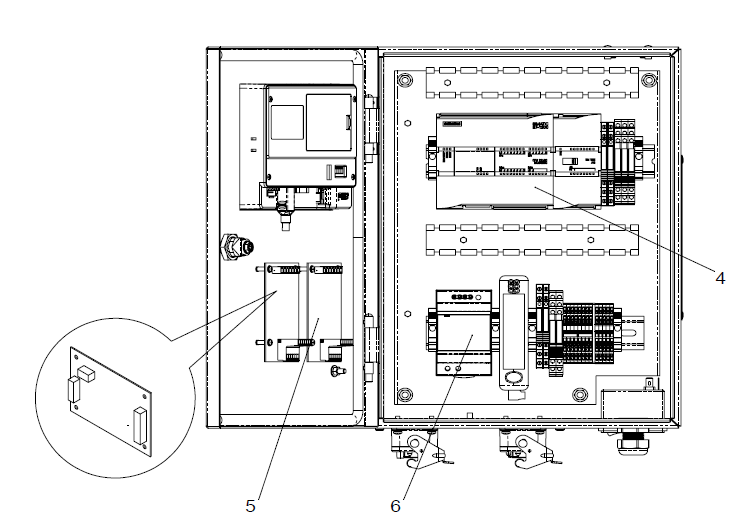

Figure 5: Internal components of the controller W/O heating zones

- 4. PLC

- 5. Meter board

- 6. DC power supply

Controller Identification

You will need the model and part number of the controller when requesting service or ordering spare parts and optional equipment. The model and part number are indicated on the equipment identification plate.

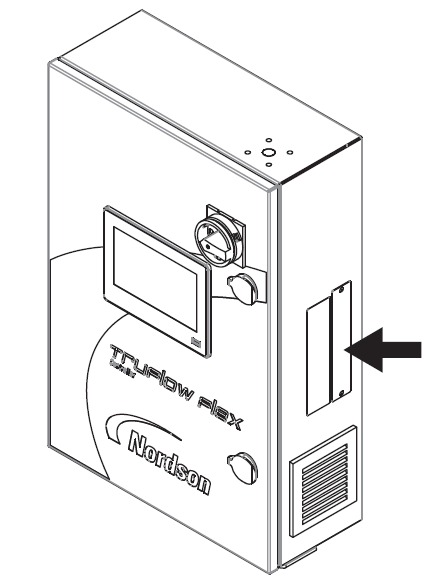

Figure 6: Location of the equipment identification plate

Figure 6: Location of the equipment identification plate

Installation

![]()

WARNING! Allow only qualified personnel to perform the following tasks. Follow the safety instructions in this document and all other related documentation.

Installation involves positioning the controller in the desired location and making the electrical connections.

For installation details on the melters, hoses, applicators, and other equipment, refer to the equipment-specific documentation.

ElectroMagnetic Compliance Information

This system is classified as Class A, Group 1 under the European standard for limits and methods of measurement, EN 55011.

Experience of Installation Personnel

The instructions provided in this section are intended to be used by personnel who have experience in the following subjects:

- Hot melt application processes

- Industrial power and control wiring

- Industrial mechanical installation practices

- Basic process control and instrumentation

Customer-Supplied Installation Components

In addition to the components provided by Nordson Corporation, installing the flow/monitor controller requires the following customer-supplied component:

- Appropriate guarding and signage as required to prevent personal injury during operation and service activities

Installation Considerations

Unpacking the Controller

- Carefully unpack the controller. Exercise care to prevent equipment damage during unpacking.

- Inspect for any damage that may have occurred during shipping. Report any damage to your Nordson representative.

Mounting Guidelines

- Position the controller as close as possible to the parent machine or production line.

- Make sure that the mounting location provides sufficient clearance around the sides, base, and rear for easy access to the connectors.

NOTE: For unhindered air flow, the recommended minimum clearance at the top and base of the unit is 50 mm (1.96 in.). - Mount the controller vertically on the wall or post to provide maximum cooling by convection across the heatsink fins.

- Mount the controller on a rigid support (e.,g. wall or post) to prevent external vibration.

Positioning and Mounting the Controller

Equipment and production line configuration may dictate a variation in the mounting options described in this section. Regardless of the mounting method used, refer to “Mounting Guidelines”.

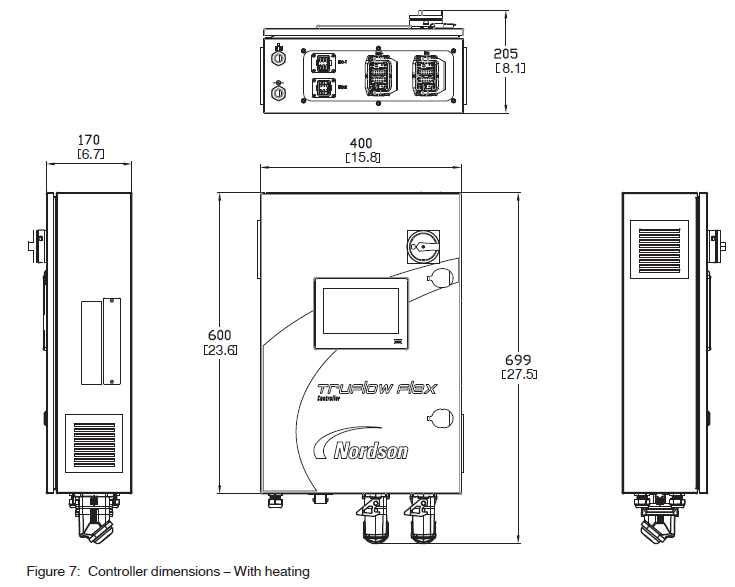

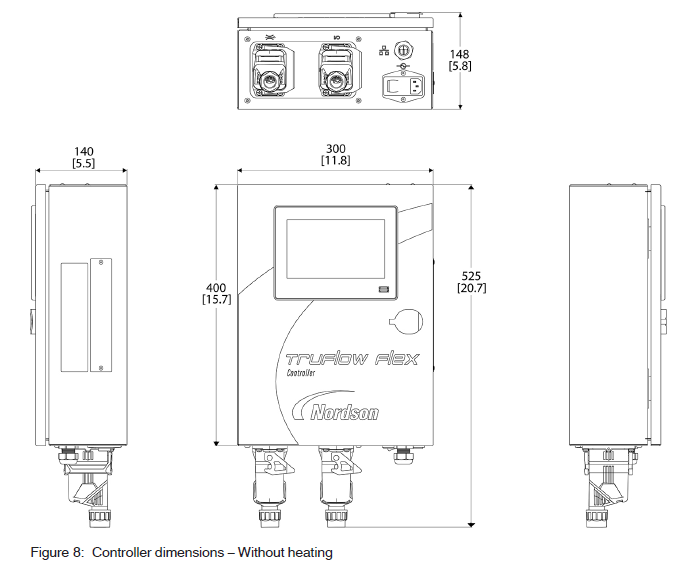

Controller Dimensions (mm [inches])

Electrical Connections

![]() WARNING! Operate only at the operating voltage shown on the ID plate.

WARNING! Operate only at the operating voltage shown on the ID plate.

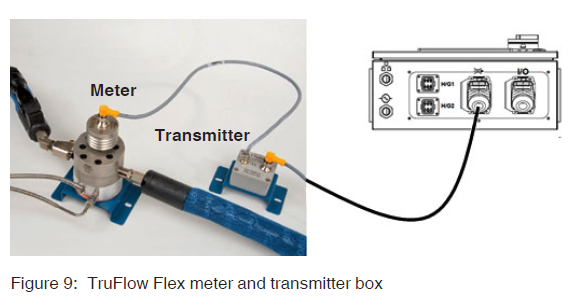

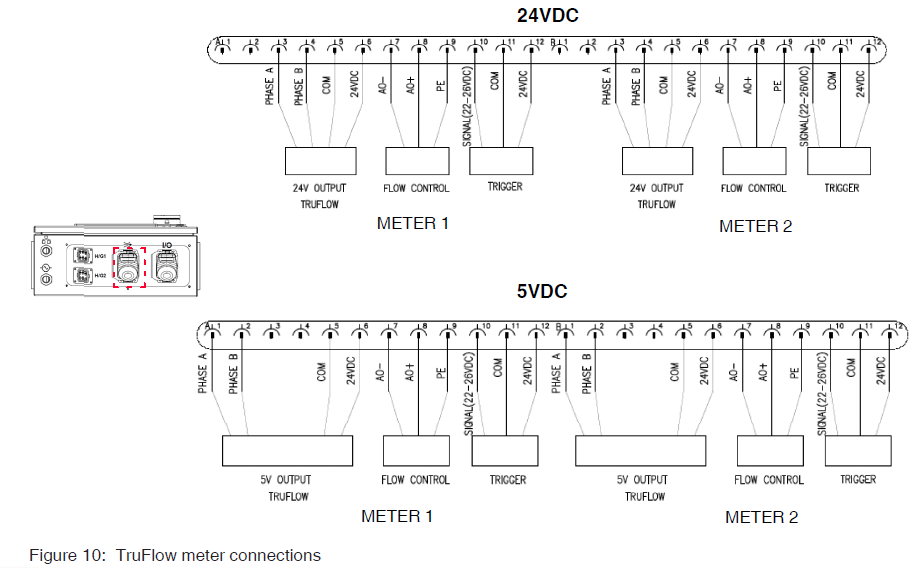

Meter Connection

The TruFlow Flex controller is designed to work with the TruFlow series of meters from Nordson.

![]() WARNING: Do not connect the TruFlow Flex controller directly to the TruFlow meter. The TruFlow Flex controller must be connected to the TruFlow transmitter box, as shown below. Connecting the TruFlow Flex Controller directly to the meter will cause meter damage.

WARNING: Do not connect the TruFlow Flex controller directly to the TruFlow meter. The TruFlow Flex controller must be connected to the TruFlow transmitter box, as shown below. Connecting the TruFlow Flex Controller directly to the meter will cause meter damage.

Figure 10 on page 26 shows the 24 VDC and 5 Vconnectionssion to a TruFlow meter.

NOTE: When installing, be sure to position the TruFlow meter facing sideways or down. This will prevent bubbles from accumulating inside the meter. In a high-pressure installation, gas bubbles may create undesirable side forces on the gears. Positioning the meter facing sideways or down will allow bubbles to be purged and reduce the amount of heat rising from the flow meter into the encoder circuitry.

Nordson recommends the following actions:

- Purge air from the meter before operating.

- Secure cabling so that it does not come into contact with heated surfaces.

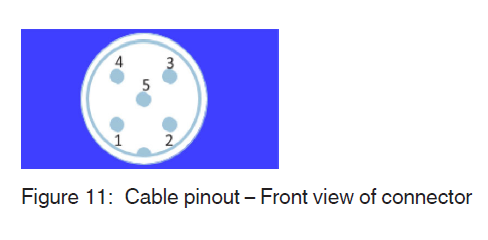

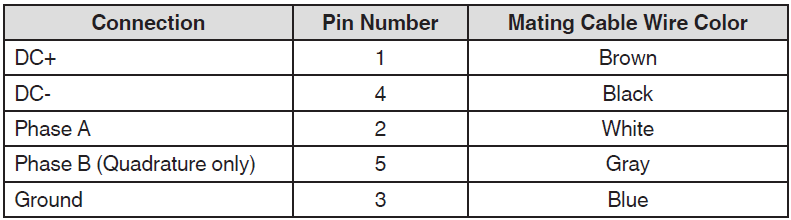

Mating Connector for the TruFlow Transmitter Box

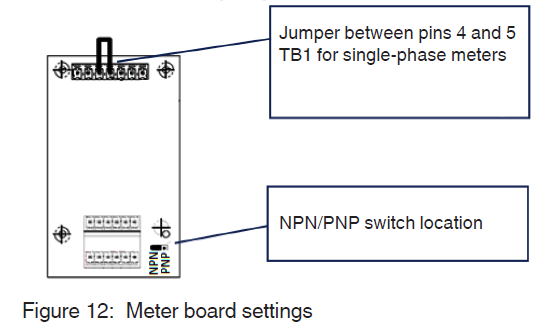

The meter boards, shown in Figure 12, must be set to work with either NPN or PNP signals from the meter. Please use the switch on each meter board to set this function for your specific meter. Also, for single-phase operation, you must place a jumper between pins 4 and 5 on TB1 as shown.

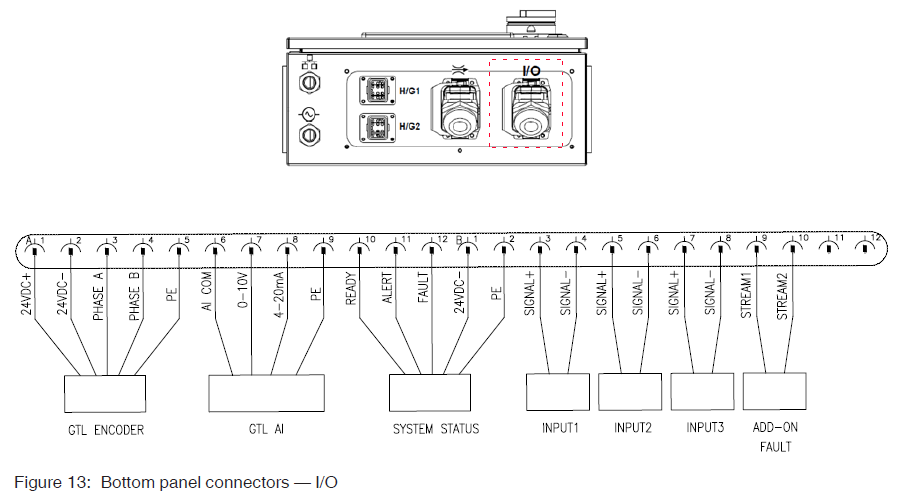

I/O Connection

The I/O provides the user with three configurable inputs and three standard outputs. The inputs are activated by applying a constant 24 VDC signal voltage, which is supplied by the customer’s control equipment. The outputs are rated for 24 VDC, 300 mA maximum load for each output.

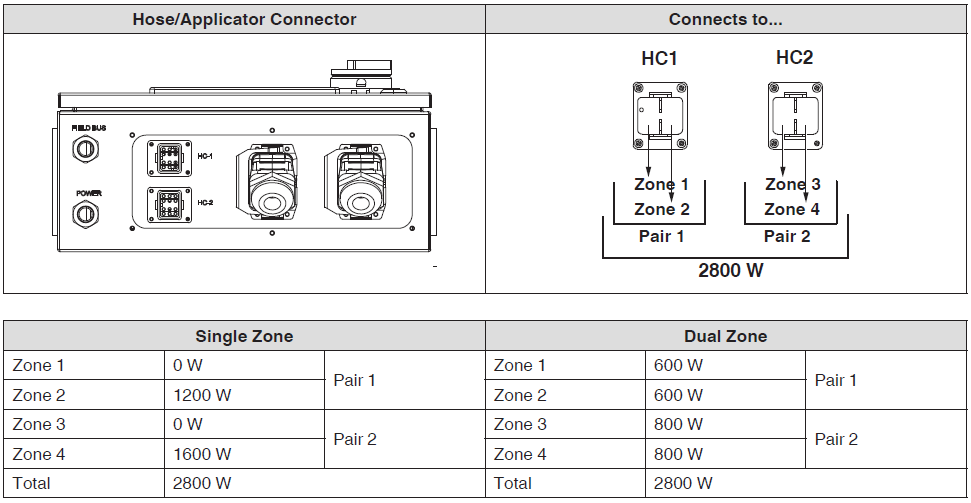

Hose/Applicator External Connections

Use these connectors to connect to external hose/applicator devices.

Controller Base Panel with Nickel RTD

Electrical Service Information

For detailed installation guidance, please refer to the TruFlow Flex Installation Guide, P/N 1129545.

Before System Setup

![]() WARNING! Allow only qualified personnel to perform the tasks in this document. Follow the safety instructions in this document and all other related documentation.

WARNING! Allow only qualified personnel to perform the tasks in this document. Follow the safety instructions in this document and all other related documentation.

Before setting up the system, make sure of the following:

- All required internal/external connections have been completed.

- The controller is connected to a melter or parent machine.

- The controller is connected to the meter.

- Hoses and applicators are connected.

- The controller power cable must include a ground connection.

- The controller power switch is turned on.

Operation

![]() WARNING! Allow only qualified personnel to perform the tasks in this document. Follow the safety instructions in this document and all other related documentation.

WARNING! Allow only qualified personnel to perform the tasks in this document. Follow the safety instructions in this document and all other related documentation.

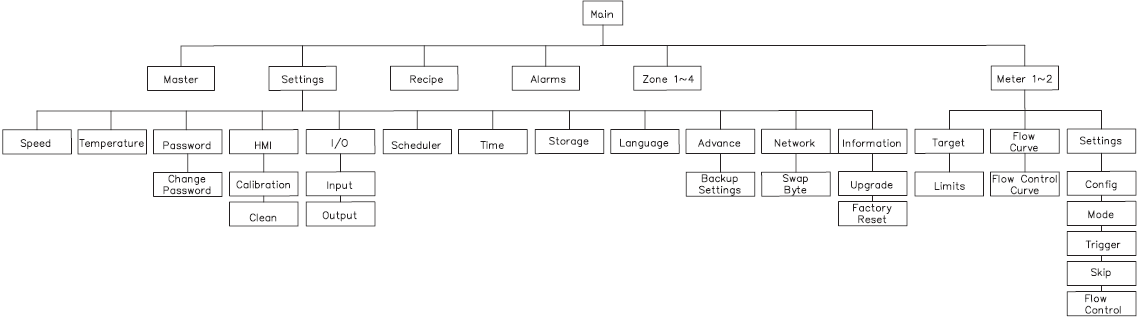

The user interface flow diagram on the following page depicts the touch screen menu hierarchy, including settings and all available options. Depending on your controller configuration, some of the items shown on the flow diagram may not be available.

Touch Screen Menu Map

Refer to the following menu map for touch screen menu information.

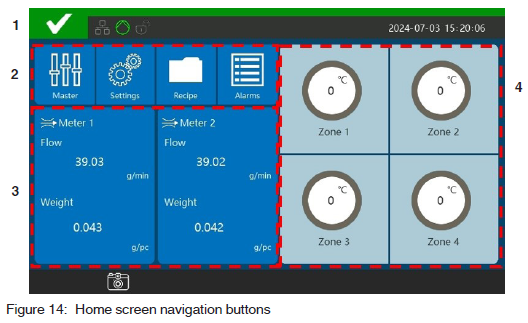

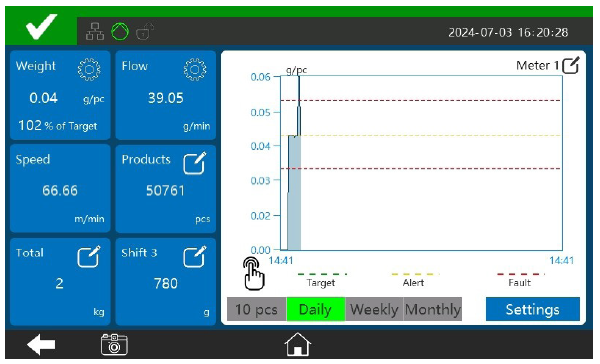

Home Screen

The Home screen allows you to navigate the graphical user interface to set up, operate, and maintain the controller.

The controller is shipped from the factory with most software settings pre-configured and ready to use. However, there are some settings that you must configure and fine-tune to best fit your manufacturing process.

Navigating the Home Screen

The following components on the Home screen allow you to navigate through the various screens for setup and operation.

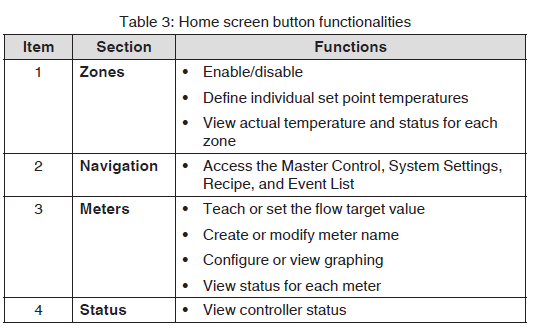

Refer to Table 3 for the Home screen button functionalities.

- Status

- Navigation button

- Meter buttons

- Zone buttons

Monitoring the Controller Status

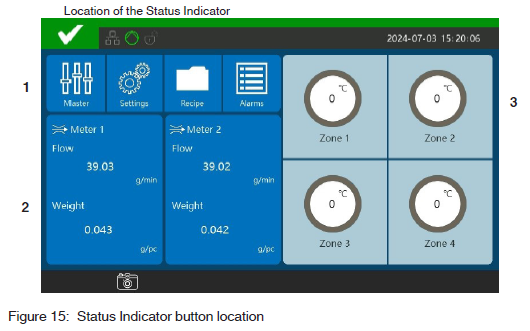

The following figure shows the location that allows you to view the controller status.

- Navigation button

- Meter buttons

- Zone buttons

Status Indicator Table

The following table details the controller status messages.

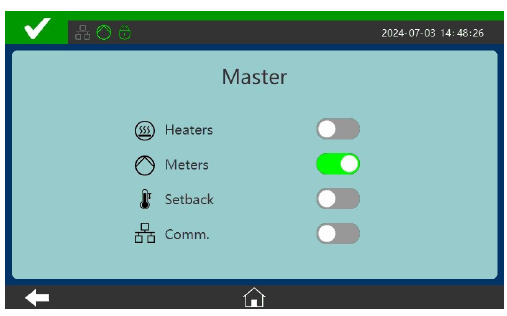

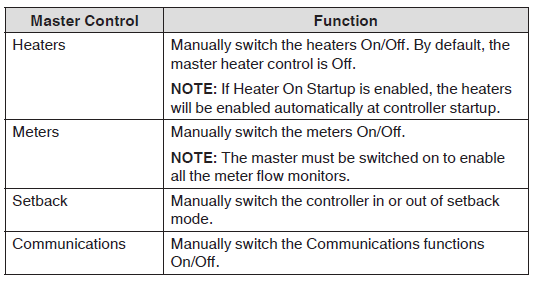

Master Controls

![]() WARNING! Allow only qualified personnel to perform the following tasks.

WARNING! Allow only qualified personnel to perform the following tasks.

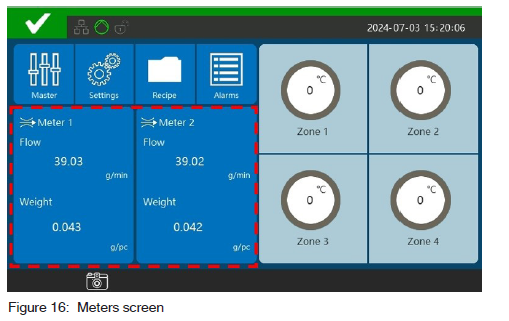

Follow the safety instructions in this document and all other related documentation. Use the Master Controls display to switch on/off the primary controls of the controller, including the heater and scheduler, as well as to manually place the controller into setback mode.

The controller is shipped from the factory with pre-configured system settings and ready to use. However, there are some settings that you must configure and fine-tune to best fit your manufacturing process.

- From the Home screen, touch

Master to access the Master Controls screen.

Master to access the Master Controls screen.

- Touch the color-coded button to switch on or off the following:

- Touch

.

.

What the Button Colors Indicate

The following table details what the Heaters, Setback, and Master Meter buttons indicate.

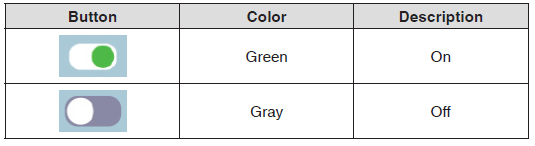

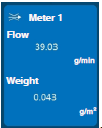

Flow Meters

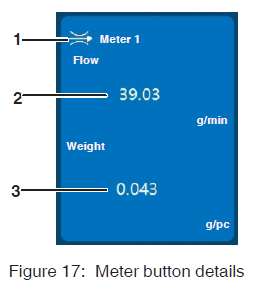

Use the Meters display screen to reconfigure the flow meter settings to best fit your manufacturing requirements. Touch the Meter button highlighted in the following figure to access the Meter display screen.

About Meter Status

Figure 17 details what a meter displays.

- Name of meter

- Real-time flow rate

- Application add-on weight

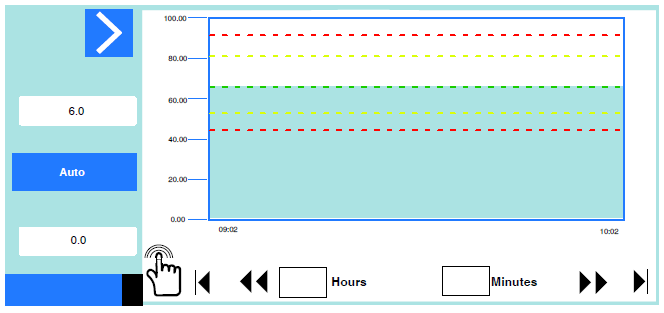

Flow Rate Monitoring

- From the Flow Rate Monitoring screen, touch

to change the data display.

to change the data display.

- From the screen, touch each View button

to change the add-on chart view.

to change the add-on chart view. - Touch the chart’s Y axis highlighted in the following figure to adjust the chart scale.

- Touch Auto to adjust the chart scale automatically.

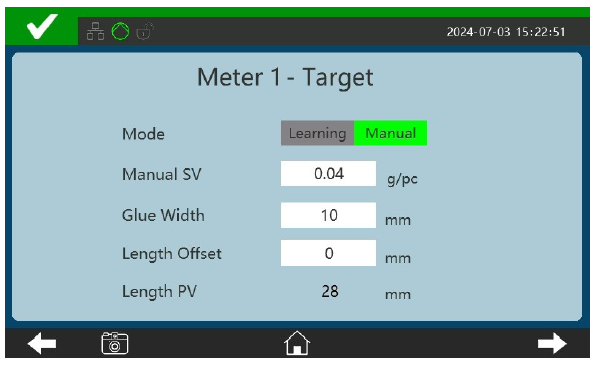

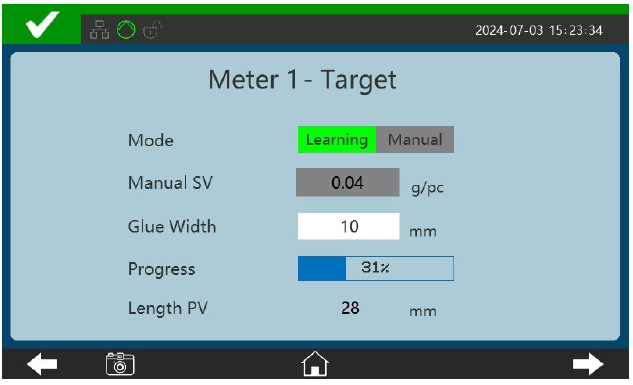

Flow Meter Runtime Setting – Target

Set the flow monitoring add-on target value to best fit your manufacturing requirements.

NOTE: The add-on target method is switched according to the application mode in the flow setting.

- From the Flow Rate Monitoring screen, touch

.

.

- Define the following settings:

- Mode

- Manual SV

- Glue Width

- Length Offset

- Length PV (Read-only)

Meter Limits

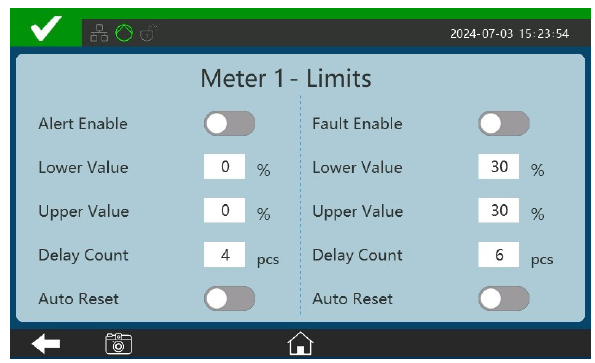

During normal operation, the system compares the measured Add-On/Product to the Alert/Fault Lower Limit and Alert/Fault Upper Limit settings. If a measured Add-On/Product value falls outside the Alert/Fault threshold settings and the number of consecutive defective products equals or exceeds the setting entered for Alert/Fault Delay Count, the system enters an alarm state and activates the Alert/Fault Output.

- From the Home screen, touch

.

. - Touch

.

. - Touch

to access the Meter Limits screen.

to access the Meter Limits screen.

- Change the settings as needed. Please note the following:

- The Alert / Fault Enable feature can be disabled.

- The Alert and Fault settings auto-reset as follows:

- Alert Auto Reset: The Alert setting will auto-reset after five seconds.

- Fault Auto Reset: The Fault setting will auto-reset with the rising of the trigger signal.

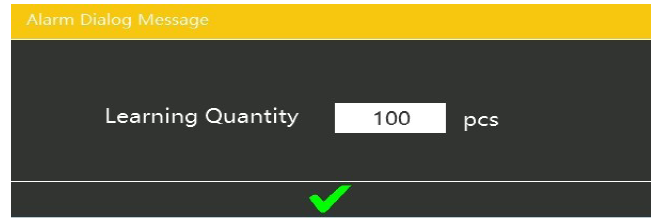

Learning

The target can be entered directly from a number keypad, or by touching Learning to let the system learn the correct value from the specified number of products or amount of time.

- From the Target screen, touch Learning.

- Touch

. The screen displays a Progress of Learning indicator.

. The screen displays a Progress of Learning indicator.

- Touch the Manual on the Target screen to stop the learning.

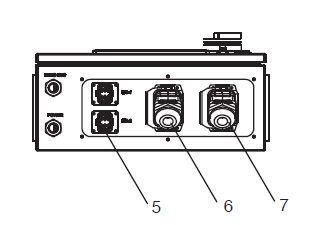

Events List

The Events list shows the most recent major events in the TruFlow Flex controller. This list can be useful for troubleshooting.

- From the Home screen, touch

to access the Events list.

to access the Events list.

- Select from the following options:

- Touch Clear to clear the screen.

- Touch Reset to reset a fault condition on the controller.

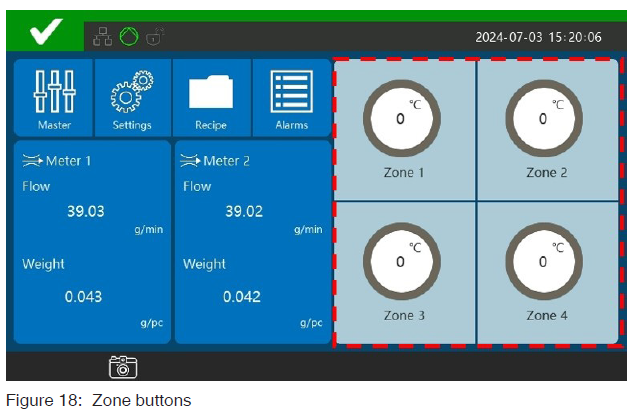

Understanding the Zones

Use the Zone display screen to reconfigure the zone settings to best fit your manufacturing requirements.

Touch any of the Zone buttons, highlighted in the following figure, to access the Zone display screen.

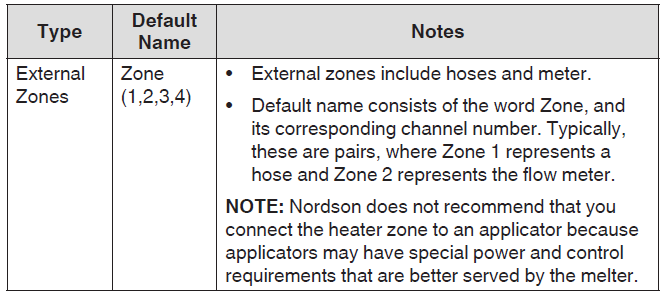

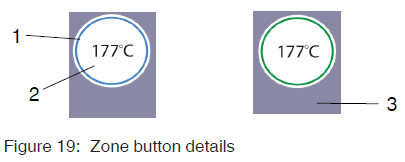

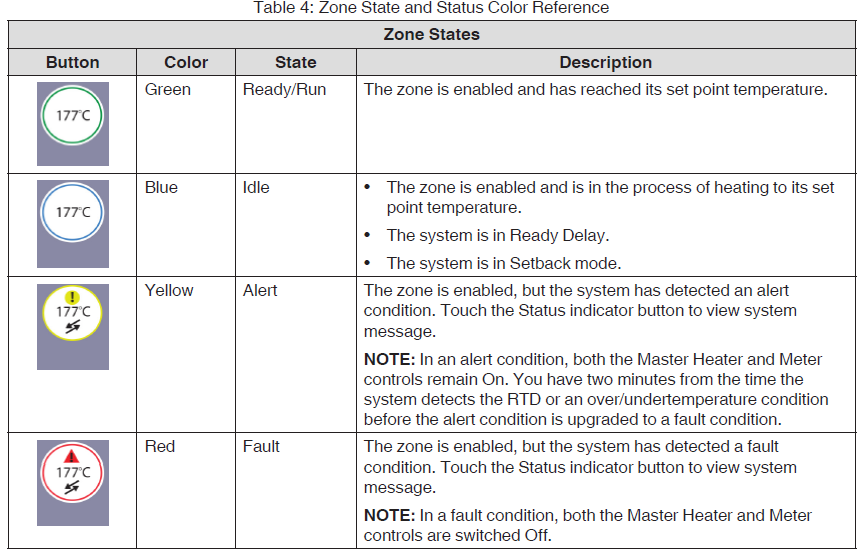

About Zone Buttons

Figure 19 details an enabled zone button display. Refer to Table 4 for a detailed list and explanation of each zone button.

- Process Ring

- Real-time temperature

- Zone name

NOTES

- You can modify zones at any time.

- Changes to set point temperatures and PID Type take effect when the zone is enabled and when the controller itself is in a Ready/OK state.

- The state of a zone is independent of the overall status of the controller.

Troubleshooting

![]() WARNING! Allow only qualified personnel to perform the following tasks. Follow the safety instructions in this document and all other related documentation.

WARNING! Allow only qualified personnel to perform the following tasks. Follow the safety instructions in this document and all other related documentation.

![]() WARNING! Observe all safety instructions and regulations concerning energized unit components (active parts). Failure to observe may result in an electric shock.

WARNING! Observe all safety instructions and regulations concerning energized unit components (active parts). Failure to observe may result in an electric shock.

This section contains troubleshooting procedures. These procedures cover only the most common problems that you may encounter. If you cannot solve the problem with the information given here, contact your local Nordson representative for help.

Safety

- Before breaking any hydraulic connection, always relieve system pressure. Refer to the melter manual for detailed instructions.

- Refer to the safety information provided with the optional equipment.

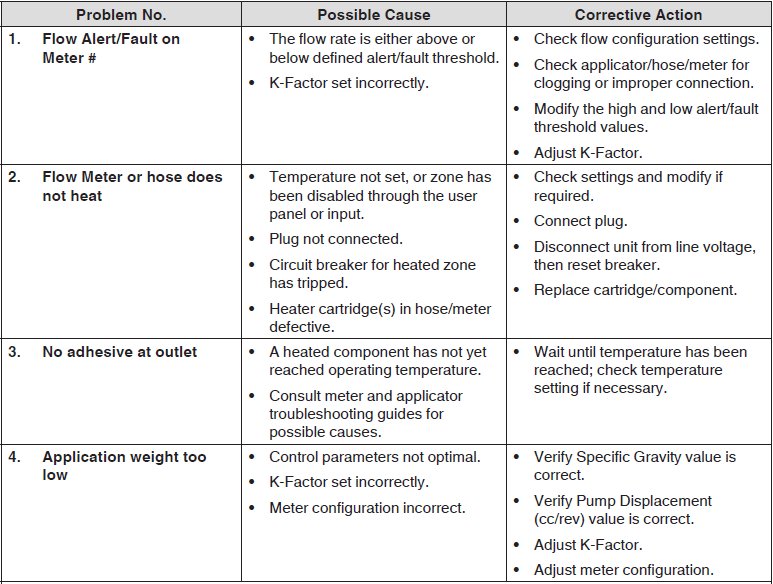

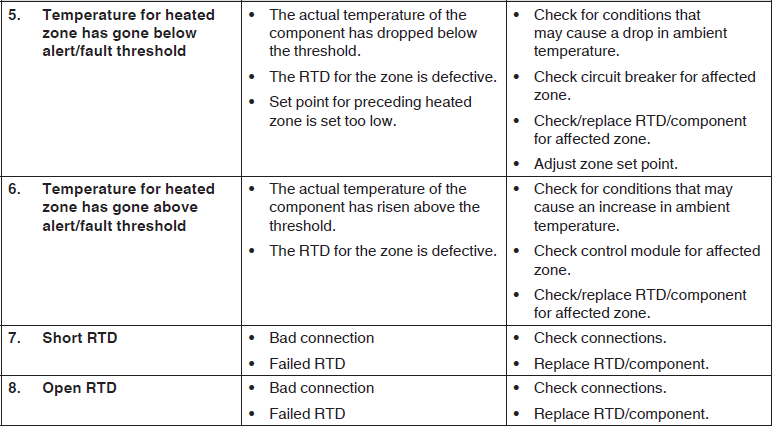

Troubleshooting Tables

The tables in this section use the Possible Cause and Corrective Action columns to help resolve the Alert or Fault condition.

Technical Data

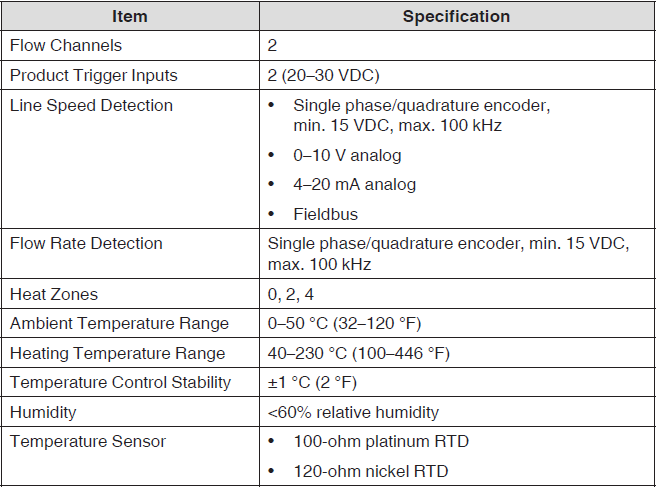

Specifications

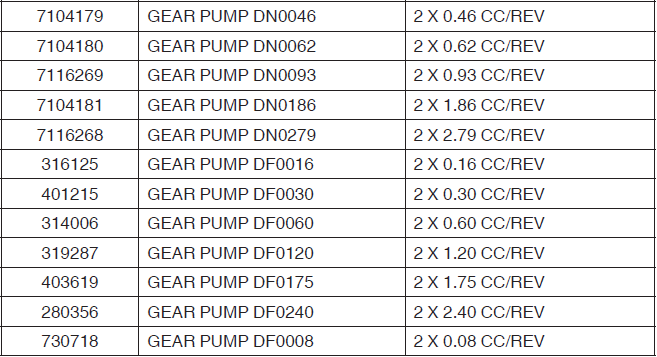

Meter

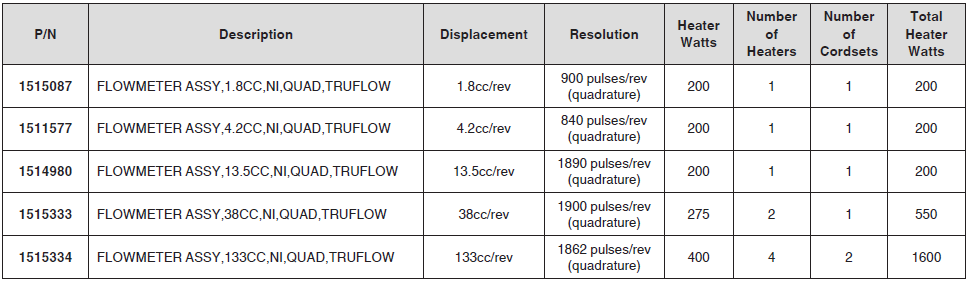

Pump

Controller

For more manuals by Nordson, visit ManualsLibraryy

Nordson TruFlow Flex Adhesive Dispensing Controller– FAQs

What is an adhesive dispensing system?

It’s a machine that applies glue or sealants with high precision. It’s used in factories to ensure the exact amount of material is put in the right place every time.

What is Nordson known for?

Nordson is a company that makes advanced equipment for dispensing, testing, and curing materials like adhesives and coatings. They are a leader in precision technology.

What is the “TruFlow Flex” system?

The TruFlow Flex is a specific Nordson dispensing system. It’s designed to be versatile and accurate, handling many different types of materials for complex manufacturing jobs.

How does precise dispensing work?

It uses a method called positive displacement. A piston or screw pushes out a specific, measured amount of fluid, which is much more accurate than just using air pressure.

Why is surface “wetting” important?

“Wetting” is when a liquid adhesive spreads out evenly on a surface. Good wetting is essential for creating a strong bond because it allows the glue to make full contact.

What does Nordson EFD do?

Common types include strong epoxies, flexible polyurethanes, heat-resistant silicones, and fast-setting cyanoacrylates (super glues). Each is chosen for specific material properties.

What does Nordson EFD do?

Nordson EFD is a division that specializes in precision dispensers, syringes, and tips for applying very small, controlled dots and lines of fluid.

Where is Nordson headquartered?

Nordson’s global headquarters are located in Westlake, Ohio, USA.

to change the data display.

to change the data display.

.

.

.

.

to access the Events list.

to access the Events list.