PREDATOR 57341 2-HP 52cc Gasoline Auger Powerhead with 6 Inch Bit

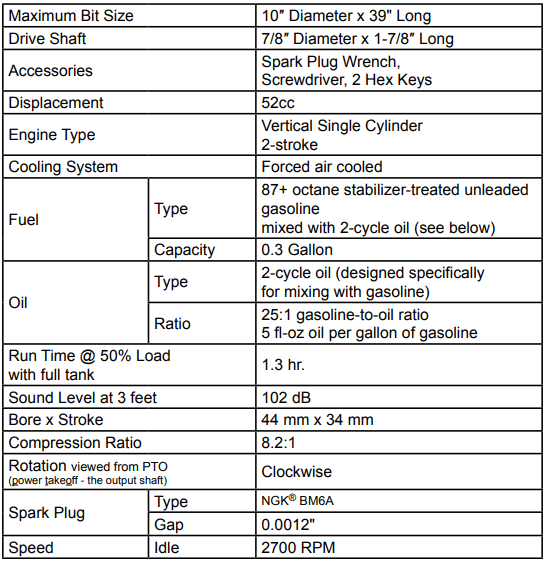

Specifications

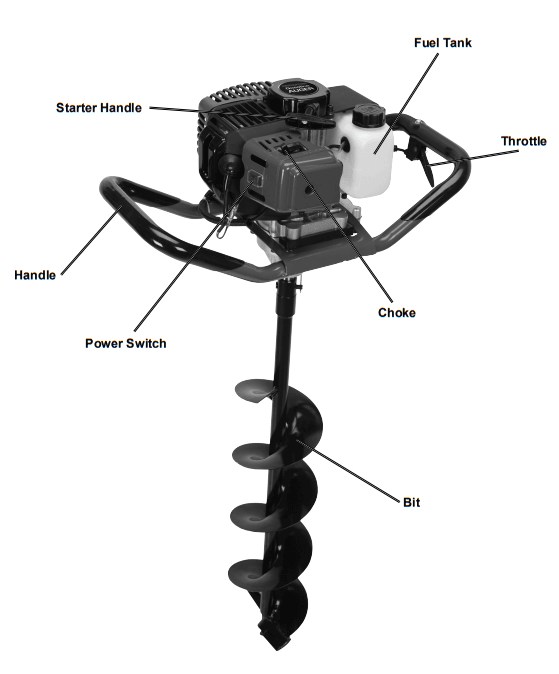

Components and Controls

Pre-Start Checks

Inspect the engine and Auger looking for damaged, loose, and missing parts before setting up and starting. If any problems are found, do not use Auger until fixed properly.

Checking and Filling Fuel

WARNING! TO PREVENT SERIOUS INJURY FROM FIRE:

Fill the fuel tank in a well-ventilated area away from ignition sources. If the engine is hot from use, shut the engine off and wait for it to cool before adding fuel. Do not smoke.

- Clean the Fuel Cap and the area around it.

- Unscrew and remove the Fuel Cap.

- Remove the Strainer and remove any dirt and debris. Then replace the Strainer.

Note: Do not use gasoline containing more than 10% ethanol (E10). Do not use E85 ethanol. Add fuel stabilizer to the gasoline, or the Warranty is VOID.

Note: Do not use gasoline that has been stored in a metal fuel container or a dirty fuel container. It can cause particles to enter the carburetor, affecting engine performance and/or causing damage.

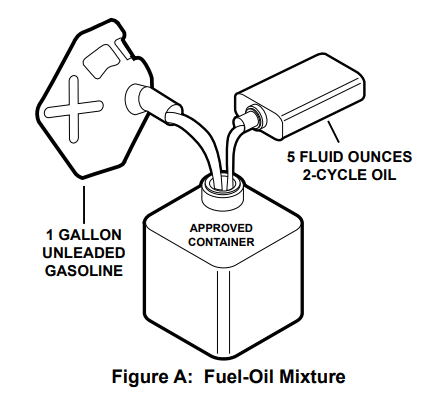

IMPORTANT: Your Warranty is VOID if the Engine’s Fuel Tank is not filled with the proper mixture (25:1) of unleaded gasoline and 2-cycle oil before each use. Before each use, check the fuel level. Do not run the Engine with an improper unleaded gasoline/2‑cycle oil mixture. Running the Engine with an improper mixture WILL permanently damage the Engine.

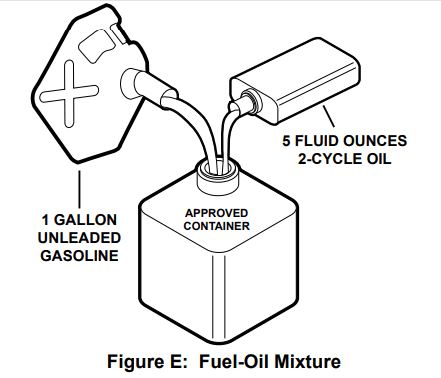

- To obtain the proper gasoline and 2-cycle oil mixture, mix 5 fluid ounces of 2-cycle oil with 1 gallon of unleaded gasoline into an approved container. Then gently agitate the container to thoroughly mix the gasoline/2-cycle oil.

- If needed, fill the Fuel Tank to about 1 inch under the fill neck of the Fuel Tank with the pre‑mixed unleaded gasoline/2-cycle oil mixture.

- Replace the Fuel Cap.

- Wipe up any spilled fuel and allow excess to evaporate before starting the engine. To prevent a fire, do not start the engine while the smell of fuel hangs in the air.

Installing Bit

- Insert the shank of the Bit fully upward into the Transmission Socket on the bottom of the Auger.

- Secure the Bit in the Transmission Socket, using the Pin and R-Pin.

Starting the Engine

Before Starting the Engine

Before starting the engine:

- Follow the Pre-start Checks to prepare the Auger.

- Inspect the Auger and engine.

- Fill the engine with the proper amount and type of unleaded gasoline and 2-cycle oil mixture.

- Check the work area for utility lines and landscaping fabric. Do not use near utility lines, and cut landscaping fabric clear before drilling.

- Read the section that follows.

- Place the Auger on its side with its Bit resting on the ground that is to be drilled.

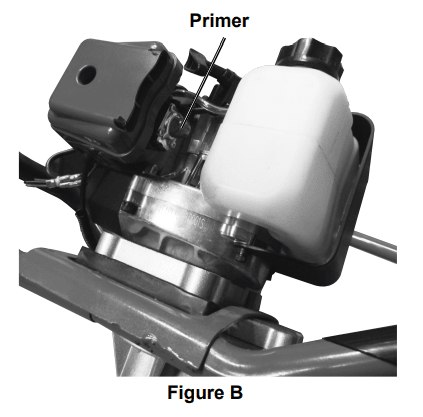

WARNING! Make sure that no debris, clothing, or other objects are near the Bit. Keep all bystanders away. - Press the Primer three or four times. See Figure B.

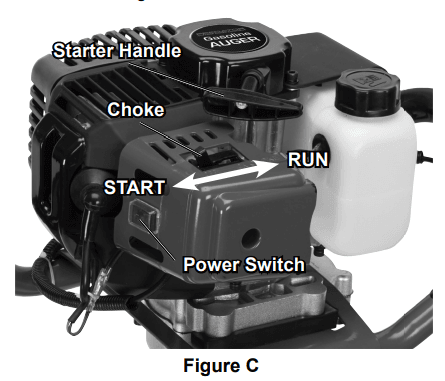

- Set the Choke (see Figure C): START if the Engine is cold. RUN if the Engine is warm.

- Move the Power Switch to the I position. Squeeze and release the Throttle.

- Grip the Frame firmly with your left hand. Keep all body parts well away from the Bit. Then, with your right hand, grip the Starter Handle of the Engine gently until resistance is felt. Allow the Cable to retract fully and then pull it quickly. Repeat until the engine starts.

Note: Do not let the Starter Handle snap back against the engine.

Hold it as it recoils so it doesn’t hit the engine. - Once the Engine is started, press the Choke down slowly to open it.

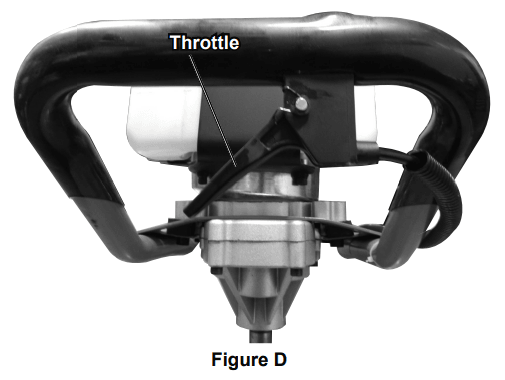

Note: Moving the Choke Lever too fast could stall the engine. - If the Engine does not start, press the Primer one more time. Raise the Choke if it is pressed down, and again attempt to start the Engine. See Figure D.

- Stand with a solid stance on stable ground. Brace yourself and maintain a proper grip with both hands on the Frame whenever the Engine is running.

- Accelerate the Engine to full throttle just before starting to drill by squeezing the Throttle. Keep the Engine at full throttle the entire time you are drilling, unless a problem arises.

- Do not drill at an angle. Keep the Bit vertical at all times.

- Allow the Bit to drill for you. Exert only light downward pressure. If you attempt to force the Auger, damage to the Auger and Bit can result. Be aware of the strong twisting forces produced by the Auger during operation.

- During drilling, periodically pull the Auger up to remove loosened earth. If loosened earth is allowed to remain in the drilled hole, the Auger will screw into the earth, become stuck, and twist violently.

NOTICE: If Auger becomes stuck, dig bit out. Do not rock auger to loosen bit. Bit will bend. - Release the Throttle as soon as the drilling is completed, allowing the Engine to idle.

NOTICE: Avoid running the Auger at full throttle without a drilling load. - After running the Auger for an extended period, allow the Engine to idle for several minutes to dissipate the heat. This will prevent some Engine parts (ignition system, piston rings, carburetor, etc.) from being damaged by overheating.

- Press the Power Switch to O to turn off the Engine.

- Clean, then store the tool in a clean, dry, safe location out of reach of children and other unauthorized people.

NOTICE:

See Long-Term Storage on page 15 for complete storage instructions.

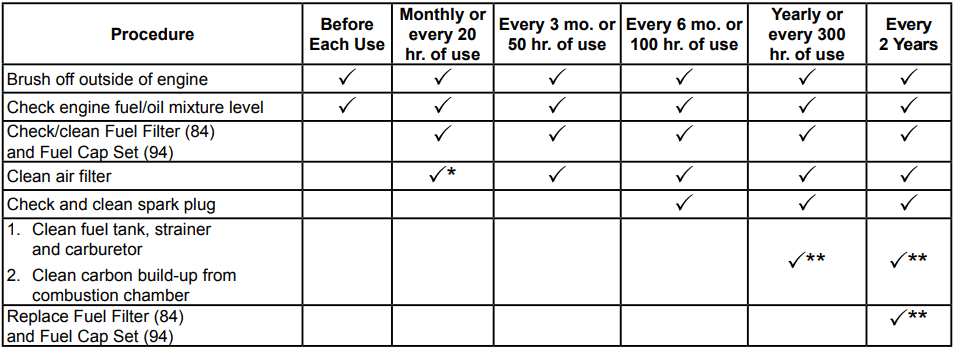

Cleaning, Maintenance, and Lubrication Schedule

Note: This maintenance schedule is intended solely as a general guide. If performance decreases or if Auger operates unusually, check systems immediately. The maintenance needs of each Auger will differ depending on factors such as duty cycle, temperature, air quality, fuel quality, and other factors.

Note: The following procedures are in addition to the regular checks and maintenance explained as part of the regular operation of the engine and Auger.

*Service more frequently when used in dusty areas.

**These items should be serviced by a qualified technician.

Daily Maintenance

- Before each use: Inspect the general condition of the Auger. Check for misalignment or binding of moving parts, cracked or broken parts, dull, bent, or damaged Bit, and any other condition that may affect the safe operation of the tool.

- A Bit that is bent or packed with dirt and debris can cause personal injury. Replace a damaged Bit and keep the Bit clean at all times.

- Check the Air Filter before each use for excessive dirt and debris buildup, and clean as needed.

- After each use, clean the exterior of the Engine with a clean cloth and mild detergent. Do not use solvents. Remove the Bit from the Engine and use a garden hose to wash off any dirt. Do not introduce liquids into the interior of the Engine.

Checking and Filling Fuel

WARNING! TO PREVENT SERIOUS INJURY FROM FIRE: Fill the fuel tank in a well-ventilated area away from ignition sources. If the engine is hot from use, shut the engine off and wait for it to cool before adding fuel. Do not smoke.

- Clean the Fuel Cap and the area around it.

- Unscrew and remove the Fuel Cap.

- Remove the Strainer and remove any dirt and debris. Then replace the Strainer.

Note: Do not use gasoline containing more than 10% ethanol (E10). Do not use E85 ethanol. Add fuel stabilizer to the gasoline, or the Warranty is VOID.

Note: Do not use gasoline that has been stored in a metal fuel container or a dirty fuel container. It can cause particles to enter the carburetor, affecting engine performance and/or causing damage.

IMPORTANT: Your Warranty is VOID if the Engine’s Fuel Tank is not filled with the proper mixture (25:1) of unleaded gasoline and 2-cycle oil before each use. Before each use, check the fuel level. Do not run the Engine with an improper unleaded gasoline/2‑cycle oil mixture. Running the Engine with an improper mixture WILL permanently damage the Engine.

- To obtain the proper gasoline and 2-cycle oil mixture, mix 5 fluid ounces of 2-cycle oil with 1 gallon of unleaded gasoline into an approved container. Then gently agitate the container to thoroughly mix the gasoline/2-cycle oil.

- If needed, fill the Fuel Tank to about 1 inch under the fill neck of the Fuel Tank with the pre‑mixed unleaded gasoline/2-cycle oil mixture.

- Replace the Fuel Cap.

- Wipe up any spilled fuel and allow excess to evaporate before starting the engine. To prevent a fire, do not start the engine while the smell of fuel hangs in the air.

Air Filter Maintenance

- Wipe off and remove the Air Cleaner Cover (79).

- Remove the Head Cover Bolt (81), the Air Filter Cover, and the plate holding the Air Filter in place. Note the placement of the plate so the bolt hole in the center is in alignment for re-assembly.

- Remove the Air Filter and check for dirt. Clean as described below.

- Cleaning:

- Wash the filter in warm water and mild detergent several times. Rinse. Squeeze out excess water and allow it to dry completely. Soak the filter in lightweight oil briefly, then squeeze out the excess oil.

- Wipe off the Air Cleaner Case (73).

- Install the cleaned filter in the reverse order of removal. Secure the Air Cleaner Cover before use.

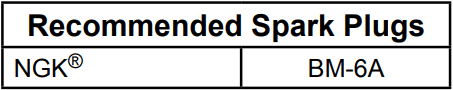

Spark Plug Maintenance

- Disconnect the spark plug wire from the end of the plug. Clean out debris from around the spark plug.

- Using a spark plug wrench, remove the spark plug.

- Inspect the spark plug: If the electrode is oily, clean it using a clean, dry rag. If the electrode has deposits on it, polish it using emery paper. If the white insulator is cracked or

chipped, the spark plug needs to be replaced.

NOTICE: Using an incorrect spark plug may damage the engine. - When installing a new spark plug, adjust the plug’s gap to the specification on the Specifications chart. Do not pry against the electrode, the spark plug can be damaged.

- Install the new spark plug or the cleaned spark plug into the engine.

- Gasket-style:

Finger-tighten until the gasket contacts the cylinder head, then tighten about 1/2-2/3 turn more. - Non-gasket-style:

Finger-tighten until the plug contacts the cylinder head, then tighten about 1/16 turn more. - NOTICE: Tighten the spark plug properly.

If loose, the spark plug will cause the engine to overheat.

If overtightened, the threads in the engine block will be damaged.

- Gasket-style:

- Apply the dielectric spark plug boot protector (not included) to the insulator of the spark plug and reattach the wire securely.

Fuel Filter Maintenance

WARNING! TO PREVENT SERIOUS INJURY FROM FIRE:

Replace or clean the Fuel Filter in a well-ventilated area away from ignition sources. Do not smoke.

- Wear protective gear including ANSI‑approved safety goggles, NIOSH-approved dust mask/respirator, and nitrile gloves.

- There is a Fuel Filter (84) hanging inside the Fuel Tank and a filter in the Fuel Cap Set (94).

- To clean, remove them from the tank and flush them with clean gas over a container to remove any debris. Replace the cleaned filter or a new filter in the tank.

- Clean up any spilled fuel.

- Wait for at least one hour before use to allow all residual fuel vapors to dissipate. To prevent a fire, do not start the Engine while the smell of fuel hangs in the air.

Long-Term Storage

When the Auger is to remain idle for longer than 20 days, prepare the Engine for storage as follows:

- CLEANING:

Wait for the Engine to cool, then clean the Engine with a dry cloth. NOTICE: Do not clean using water. The water will gradually enter the Engine and cause rust damage. Apply a thin coat of rust preventive oil to all metal parts. - FUEL:

To protect the fuel tank during storage, fill the tank with gasoline Follow Refer to Checking and Filling Fuel on page 13.

WARNING! TO PREVENT SERIOUS INJURY FROM FIRE: in a well-ventilated area away from ignition sources. If the engine is hot from use, shut the engine off and wait for it to cool before adding fuel. Do not smoke. - LUBRICATION:

- Clean out area around spark plug. Remove spark plug and pour one tablespoon of engine oil into cylinder through spark plug hole.

- Replace the spark plug, but leave the spark plug wire disconnected.

- Pull the Starter Handle to distribute oil in the cylinder. Stop after one or two revolutions when you feel the piston start the compression stroke (when you start to feel resistance).

- STORAGE AREA:

Cover and store in a dry, level, well-ventilated area out of reach of children. The storage area should also be away from ignition sources, such as water heaters, clothes dryers, and furnaces.

NOTICE: During extended storage periods, the Engine must be started every 3 months and allowed to run for 15 – 20 minutes, or the Warranty is VOID. - AFTER STORAGE:

Before starting the Engine during or after storage, keep in mind that untreated gasoline will deteriorate quickly. Drain the fuel tank and change to fresh fuel if untreated gasoline has been sitting for a month, if treated gasoline has been sitting beyond the fuel stabilizer’s recommended period, or if the Engine does not start.

Troubleshooting

The engine will not start

Possible Causes:

- FUEL RELATED:

- No fuel in tank or fuel valve closed.

- Choke not in START position, cold engine.

- Gasoline with more than 10% ethanol is used. (E15, E20, E85, etc.)

- Low quality or deteriorated, old gasoline/oil mixture.

- Carburetor not primed.

- Dirty fuel passageways.

- The carburetor needle stuck. Fuel can be smelled in the air.

- Too much fuel in the chamber. This can be caused by the carburetor needle sticking.

- Clogged Fuel Filter.

- IGNITION (SPARK) RELATED:

- Spark plug wire not connected securely.

- The spark plug electrode is wet or dirty.

- Incorrect spark plug gap.

- The spark plug wire or the spark plug is broken.

- Incorrect spark timing or a faulty ignition system.

- COMPRESSION RELATED:

- Cylinder not lubricated.

Problem after long storage periods. - Loose or broken spark plug.

(Hissing noise will occur when trying to start.) - Loose cylinder head or damaged head gasket.

(Hissing noise will occur when trying to start.) - Engine valves or tappets mis‑adjusted or stuck

- Cylinder not lubricated.

Probable Solutions:

- FUEL RELATED:

- Fill fuel tank with fresh 87+ octane stabilizer-treated unleaded gasoline and open fuel valve. Do not use gasoline with more than 10% ethanol (E15, E20, E85, etc.).

- Move Choke to the START position.

- Clean out ethanol rich gasoline from fuel system. Replace components damaged by ethanol. Use fresh 87+ octane stabilizer-treated unleaded gasoline/oil mixture only. Do not use gasoline with more than 10% ethanol (E15, E20, E85, etc.).

- Use fresh 87+ octane stabilizer-treated unleaded gasoline/oil mixture. Do not use gasoline with more than 10% ethanol (E15, E20, E85, etc.).

- Press the Priming Bulb to prime.

- Clean out passageways using a fuel additive. Heavy deposits may require further cleaning.

- Gently tap the side of the carburetor float chamber with the screwdriver handle.

- Turn Choke to RUN position. Remove spark plug and pull the start handle several times to air out the chamber. Reinstall spark plug and set Choke to START position.

- Replace Fuel Filter.

- IGNITION (SPARK) RELATED:

- Connect the spark plug wire properly.

- Clean the spark plug.

- Correct spark plug gap.

- Replace spark plug wire and/or spark plug.

- Have a qualified technician diagnose/repair the ignition system.

- COMPRESSION RELATED:

- Pour a tablespoon of oil into the spark plug hole. Crank the engine a few times and try to start again.

- Tighten the spark plug.

If that does not work, replace the spark plug.

If the problem persists, you may have a head gasket problem, see #3. - Tighten head.

If that does not remedy the problem, replace the head gasket. - Have a qualified technician adjust/ repair valves and tappets.

Auger rotates while the Engine is idle

Possible Causes:

Engine idle Speed set too high.

Probable Solutions:

Have qualified technician reset carburetor Idle Screw to lower idle (RPM) speed, see Warning on page 11.

The gearbox feels exceptionally hot to the touch

Possible Causes:

Low level of gear oil.

Probable Solutions:

Immediately turn off the Auger. Allow the gearbox to completely cool. Discontinue using Auger until the gearbox is repaired by a qualified service technician.

The power switch does not turn off the Engine

Possible Causes:

Faulty Power switch.

Probable Solutions:

- Immediately remove the spark plug cap from the spark plug to stop the Engine.

- Discontinue using the Auger until the tool is repaired by a qualified service technician.

The engine runs, but Bit is not rotating

Possible Causes:

- The throttle was not properly used.

- The throttle cable is not properly adjusted.

- Bit stuck in rocks, roots, etc.

Probable Solutions:

- Make sure to fully squeeze the Throttle.

- Have a qualified service technician adjust the Throttle cable.

- Remove the Bit from the hole and clear the hole of obstructions.

Warranties

Limited 90-Day Warranty (Retail)

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence, or accidents, repairs or alterations outside our facilities, criminal activity, improper installation, normal wear and tear, or to a lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent, special or consequential damages arising from the use of our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY INSTEAD OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, EXCEPT FOR THE EMISSIONS CONTROL SYSTEM WARRANTY BELOW.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection verifies the defect, we will either repair or replace the product at our discretion, or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement.

We will return repaired products at our expense, but if we determine there is no defect or that the defect resulted from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Emissions Control System Warranty

Harbor Freight Tools (HFT) is pleased to explain the emissions control system warranty on your Small Off-Road Engine produced after January 1, 2015 (engine), in addition to the Retail Warranty above. HFT warrants that the emissions control system on your engine is designed, built, and equipped so that it conforms to the United States Environmental Protection Agency’s (EPA) emissions requirements in effect at the time of manufacture.

HFT also warrants that the emissions control system on your engine will be free from defects in material and workmanship for two (2) years, provided there has been no improper maintenance, misuse, or abuse of your engine.

For more manuals by PREDATOR, visit ManualsLibraryy

PREDATOR 57341 2-HP 52cc Gasoline Auger Powerhead with 6 Inch Bit- FAQs

What type of fuel does the Predator 57341 auger use?

The Predator auger uses unleaded regular gasoline mixed at a 50:1 fuel-to-oil ratio.

What is the purpose of an auger motor?

An auger motor powers the rotation of the auger to move material or fuel efficiently—whether that’s feeding pellets into a stove or drilling into the ground.

How deep can the Predator gas auger dig?

Typically, this auger can dig 3 to 4 feet deep. For greater depth, you can attach an extension rod to reach an extra 12 inches or more.

What are the bore and stroke of the Predator 224cc engine?

The engine features a 70mm bore and a 58mm stroke, providing powerful and efficient performance.

What is the typical auger rotation speed?

For practical operation:

1. 4-inch augers run up to 1,000 RPM

2. 6-inch augers run best at around 800 RPM

What does “auger overcurrent” mean?

This error typically occurs when the auger motor is jammed or damaged, often due to wet pellets or foreign objects. It’s most common in smart or WiFi-enabled augers.

How does an auger work?

An auger uses a rotating spiral shaft (called a “flighting”) to drill, cut, or move material. As it spins, the blade digs into the surface and transports the material out of the hole.

Are augers safe to use?

While effective, augers can pose risks. Hazards include moving belts, winches, rotating screws, and potential tipping. Always follow safety instructions and wear protective gear.