RKI Instruments M2A-XL Stand Alone Transmitter

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in materials, workmanship, and performance for a period of one year from the date of shipment from RKI Instruments, Inc. Any parts found defective within that period will be repaired or replaced, at our option, free of charge. This warranty does not apply to those items which by their nature are subject to deterioration or consumption in normal service, and which must be cleaned, repaired, or replaced on a routine basis. Examples of such items are:

- Absorbent cartridges

- Pump diaphragms and valves

- Fuses

- Batteries

- Filter elements

Warranty is voided by abuse, including mechanical damage, alteration, rough handling, or repair procedures not in accordance with the operator’s manual. This warranty indicates the full extent of our liability, and we are not responsible for removal or replacement costs, local repair costs, transportation costs, or contingent expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI INSTRUMENTS, INC., INCLUDING BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF ITS PRODUCTS OR THE FAILURE OF ITS PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and representatives appointed by RKI Instruments, Inc. We do not assume indemnification for any accident or damage caused by the operation of this gas monitor, and our warranty is limited to the replacement of parts or our complete goods.

Introduction

Overview

This chapter briefly describes the M2A Transmitter. This chapter also describes the M2A Transmitter Operator’s Manual (this document). Table 1 at the end of this chapter lists the specifications for the M2A.

About the M2A Transmitter

The M2A transmitter is a fixed-mount, continuous-monitoring detector head. All user-adjustable parameters can be accessed using push-button switches. In addition, calibration may be performed non-intrusively by use of a magnetic wand accessory, which activates magnetic switches through a window at the front face of the detector head.

The M2A displays the current gas reading on an OLED display, which is visible through the window in the cover (front face), and provides a 4 – 20 mA signal that indicates the target gas reading for use by a gas monitoring controller, recording device, or programmable controller. The M2A also provides an RS-485 Modbus output. Three sets of relay contacts, two controlled by the gas alarms and one by the fail alarm, rated at 115 VAC 5 amps, are available for controlling devices such as lights or horns or for controlling higher-rated relays.

Four operating modes allow you to display and change setup and calibration settings, and change the gas type. They are Calibration Mode, Configuration Mode, Gas Type Mode, and Modbus Mode.

About this Manual

The M2A Transmitter Operator’s Manual uses the following conventions for notes, cautions, and warnings.

- NOTE: Describes additional or critical information.

- CAUTION: Describes potential damage to equipment.

- WARNING: Describes potential danger that can result in injury or death.

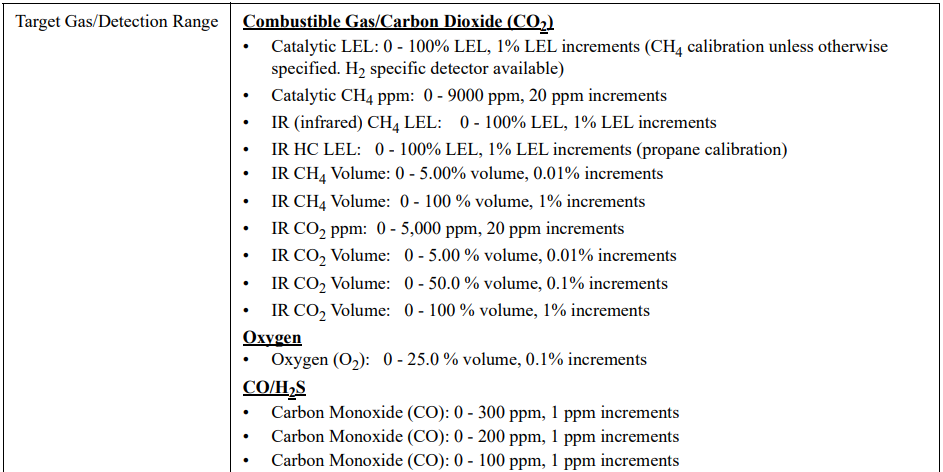

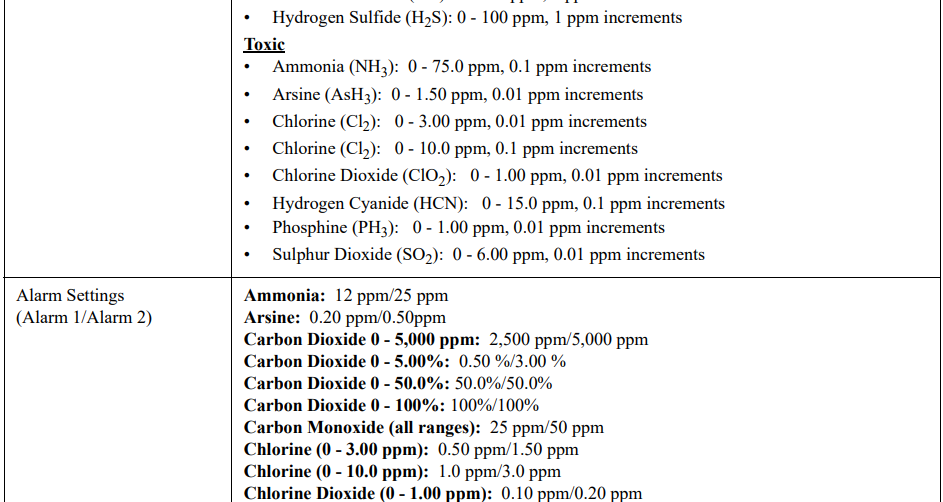

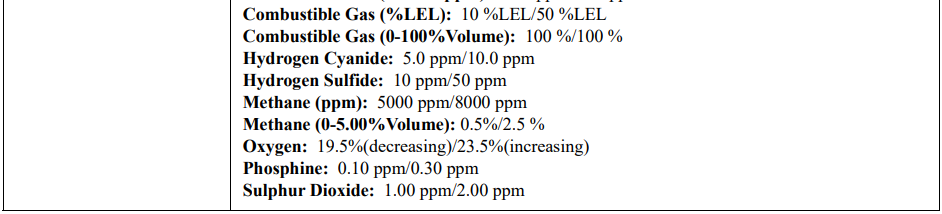

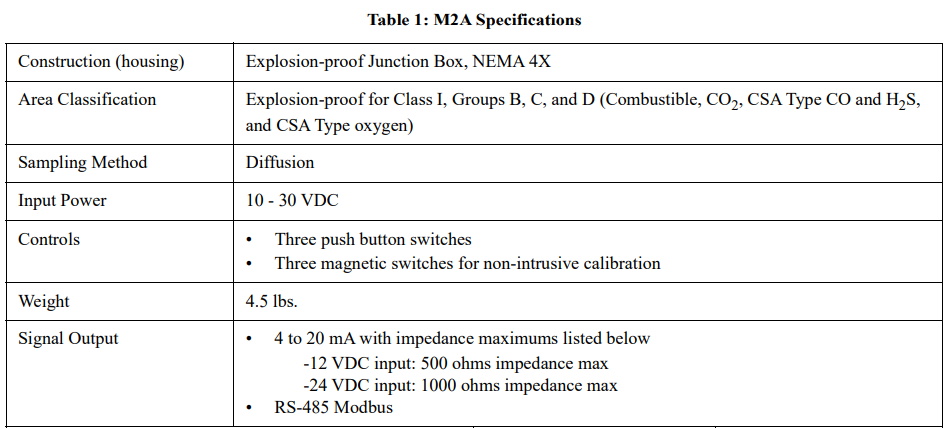

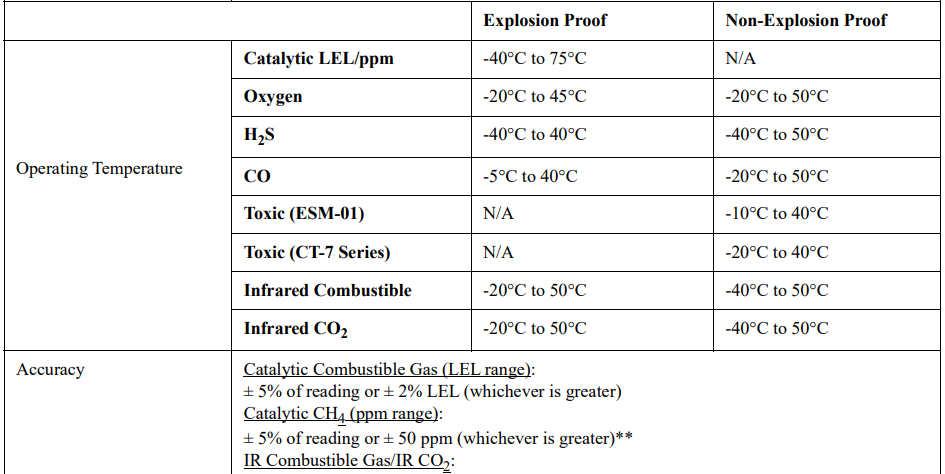

Specifications

Table 1 lists specifications for the M2A.

Description

Overview

This chapter describes external and internal components of the M2A Transmitter.

External Description

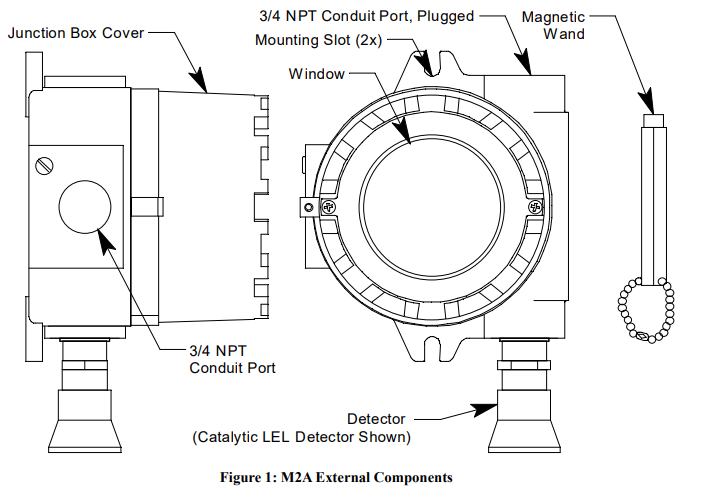

This section describes the junction box and all external components of the M2A transmitter.

Junction Box

The M2A’s cast aluminum junction box is dust and weather-resistant. The junction box also protects the M2A and all connections made to it. Use the three 3/4 NPT conduit ports to mount the detector to the junction box (factory installed in the bottom port) and connect wiring from an external device (left port). The top port is shipped with a factory-installed and sealed conduit plug to avoid leaks into the junction box. If necessary, the conduit plug can be removed, and the top port can be used for wiring.

Use the junction box’s two mounting holes to mount the M2A to a vertical surface at the monitoring site. The window in the cover on the front of the junction box allows you to view the OLED display and use the magnetic wand to actuate the magnetic control switches so you can perform non-intrusive calibration. Removing the cover allows you to access the interior of the junction box.

Magnetic Wand

The magnetic wand is a short plastic rod with a magnet on one end. It is used to actuate the magnetic control switches on the control PCB while the junction box cover is still installed, so that non-intrusive calibration can be performed.

Gas Detector

The gas detector senses the target gas and is mounted in a 3/4 NPT conduit port on the right bottom side of the M2A. A variety of detectors may be used with the M2A. See the sections below for descriptions of each type of detector.

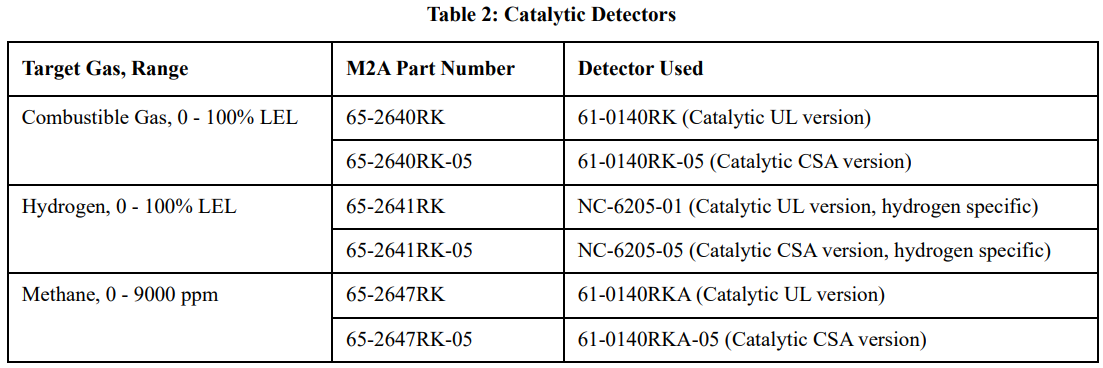

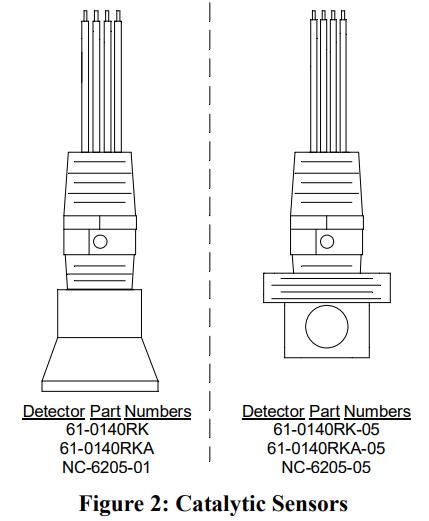

Catalytic Detectors

The catalytic detectors have a 1/2 NPT thread and require a 3/4 NPT x 1/2 NPT reducer to install in the detector port. The table below outlines the M2A part numbers and replacement detector part numbers for the catalytic detectors.

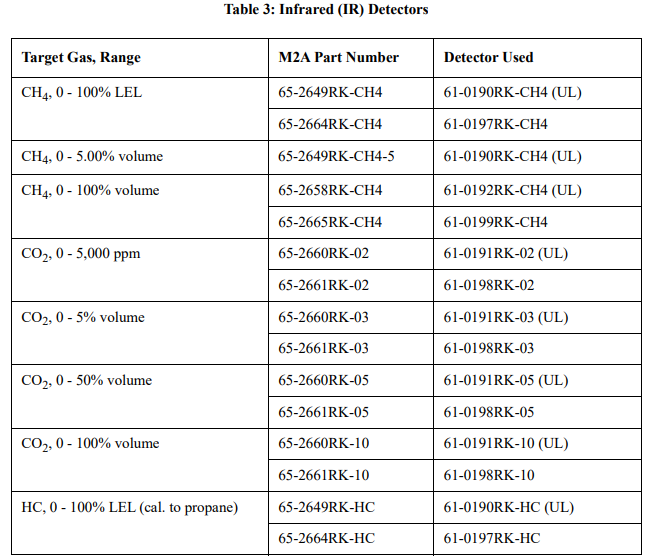

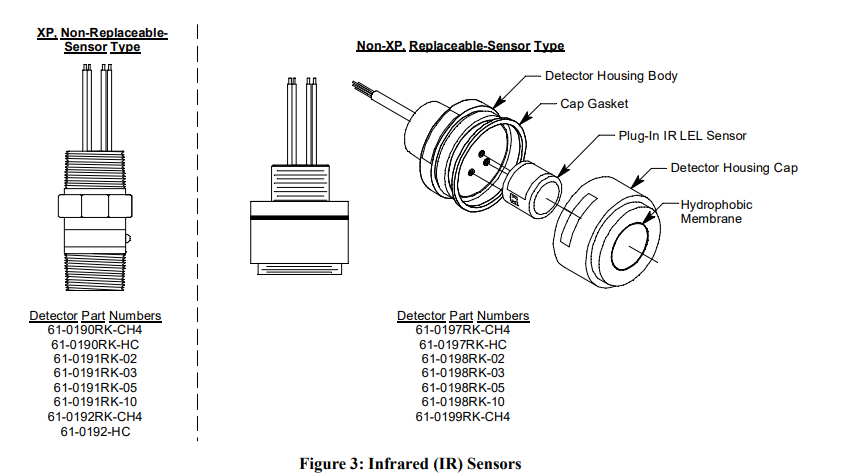

Infrared (IR) Detectors

The IR combustible detectors are generally used instead of the catalytic combustible detectors in applications where there may be catalyst poisons, such as silicone present, or where oxygen is not present in the monitoring environment. The table below outlines the M2A part numbers and replacement detector part numbers for the infrared (IR) detectors.

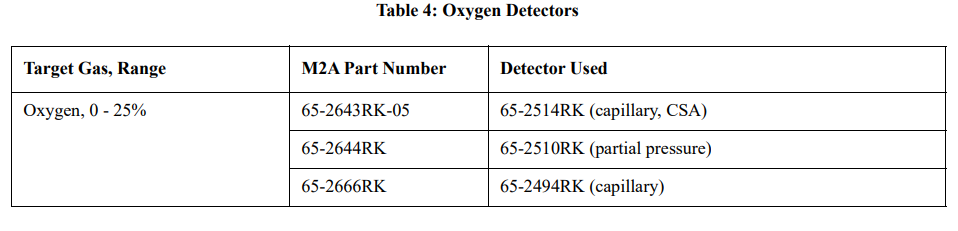

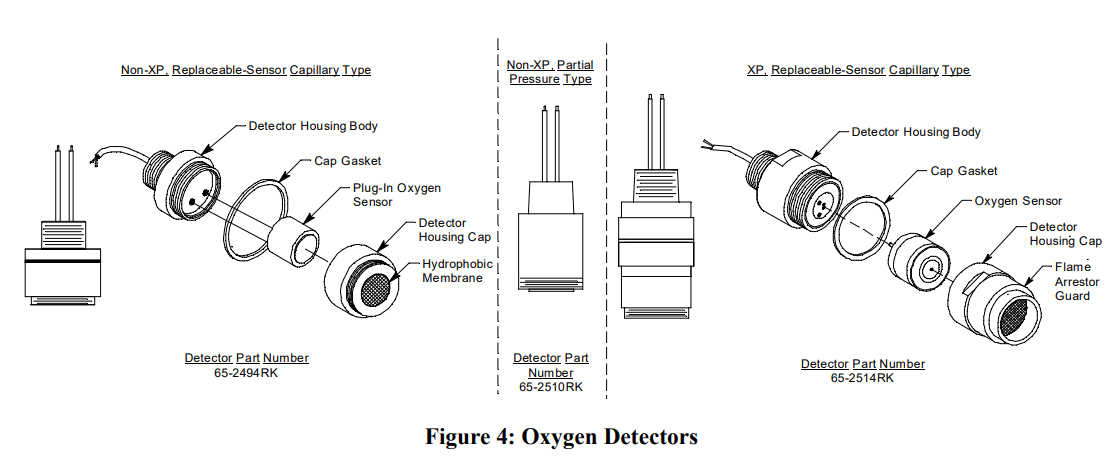

Oxygen Detectors

There are three types of oxygen detectors available: a non-explosion-proof partial pressure type, a non-explosion-proof capillary type with a replaceable sensor, and an explosion-proof (CSA) capillary type with a replaceable sensor. The capillary type’s output is less susceptible to variations in atmospheric pressure than the partial pressure type.

The CSA-type oxygen detector (65-2514RK) and the non-explosion-proof capillary type detector (65-2494RK) have a replaceable plug-in sensor inside the detector housing. The entire oxygen detector must be removed if replacement is required for the 65-2510RK. The table below outlines the M2A part numbers and replacement detector part numbers for the oxygen detectors.

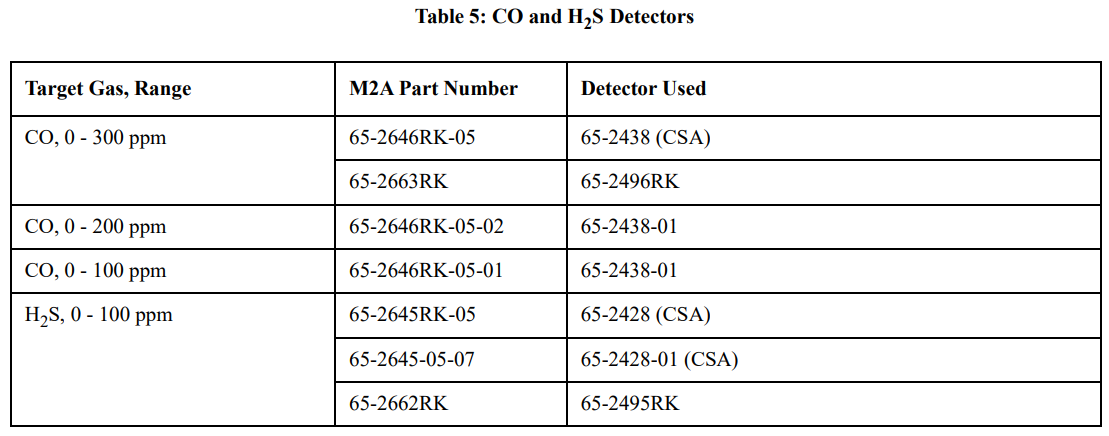

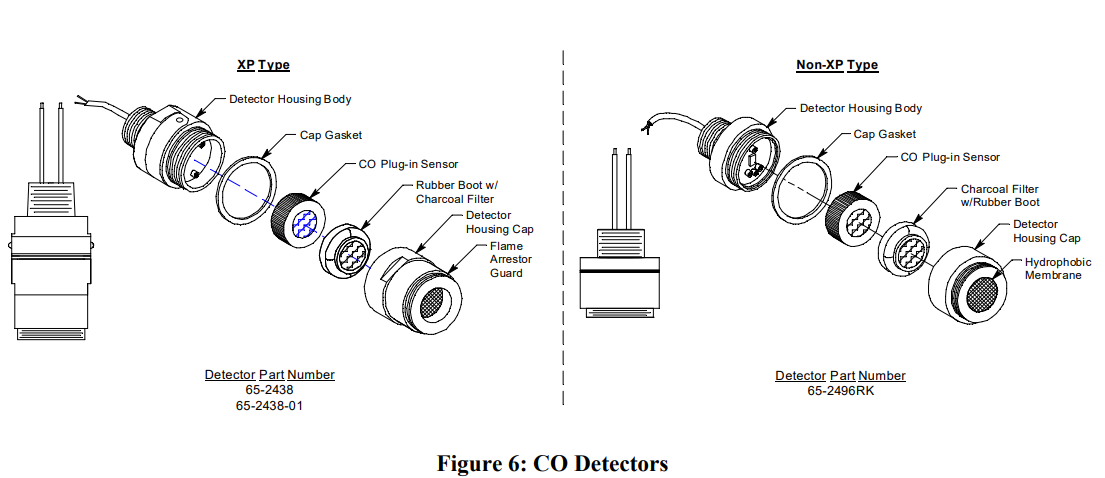

CO and H2S Detectors

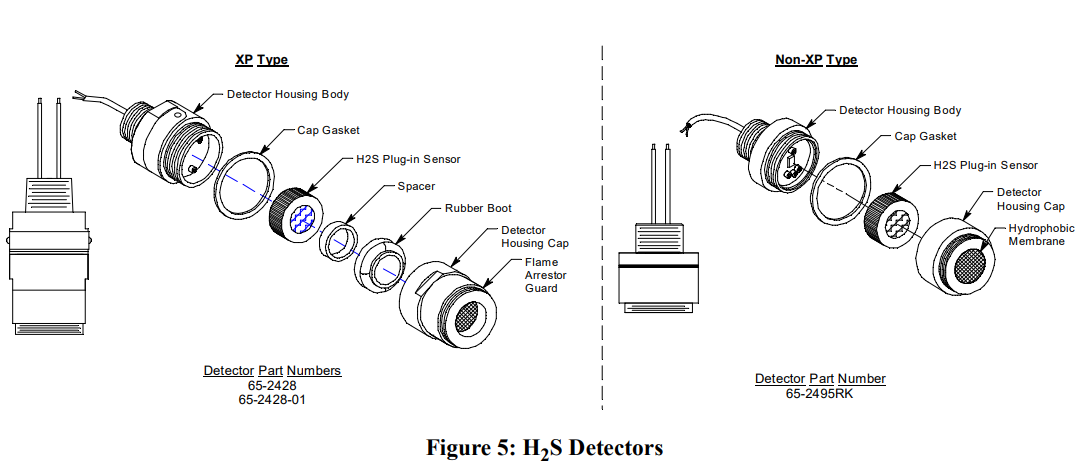

Both types of CO and H2S detectors (explosion-proof and non-explosion-proof) have replaceable plug-in sensors inside the detector housing. The CO detectors include a charcoal filter disk, which is held onto the sensor with a rubber retaining boot. The charcoal filter disk scrubs out interfering gases to which the CO sensor responds, such as H2S and certain hydrocarbons.

The 65-2428 and 65-2428-01 explosion-proof H2S detectors both include a rubber boot and a spacer that helps ensure that the sensor remains plugged into the detector housing body. The only difference between the 65-2428 and the 65-2428-01 is that the sensor used in the 65-2428-01 is resistant to degradation caused by frequent exposure to low levels of H2S or occasional exposure to high levels of H2S.

The 65-2495RK non-explosion-proof H2S detector includes an adhesive-backed gasket inside the detector housing cap, which helps ensure that the sensor remains plugged into the detector housing body. The table below outlines the M2A part numbers and replacement detector part numbers for the CO and H2S detectors.

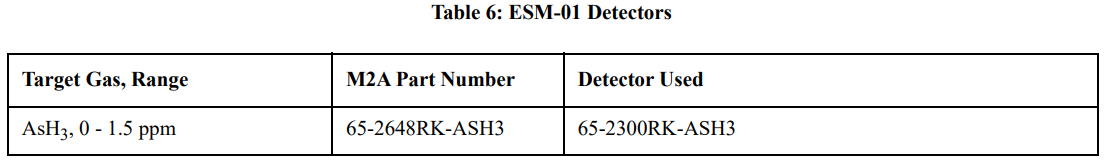

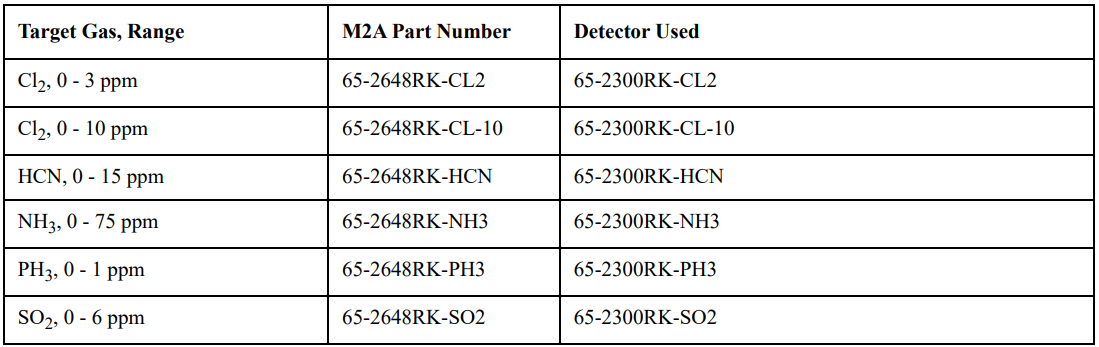

ESM-01 Detectors

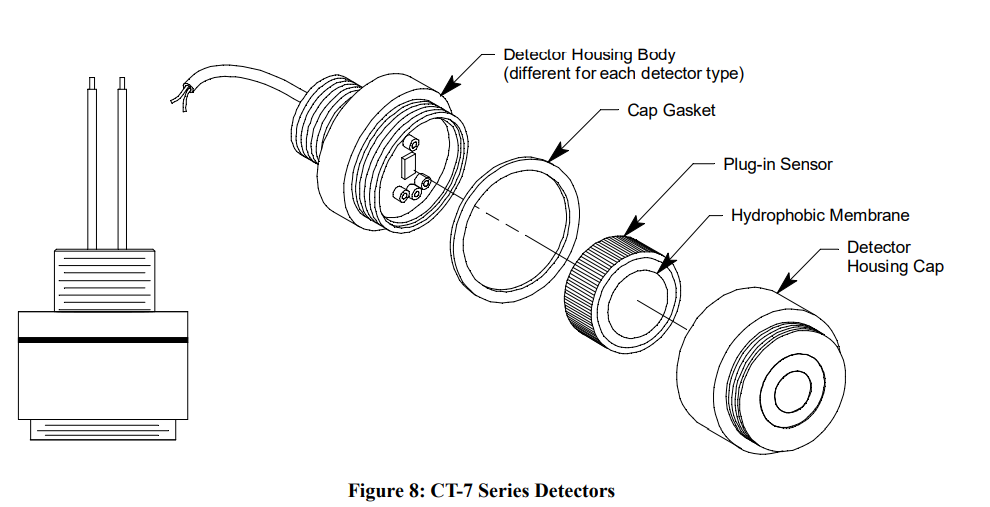

The construction of the various ESM-01 detectors is similar. Each of the ESM-01 detectors has a different replaceable plug-in sensor that protrudes through the detector housing cap. Although ESM-01 detectors look the same except for the plug-in detector, the detector housing, which includes the detector socket and conditioning circuitry, is specific to a sensor type. For example, a detector housing from a Cl2 detector cannot be used with an NH3 detector.

One of the two detector wires is color-coded for each specific detector type. The ESM-01 detectors include a removable splashguard that screws onto the detector housing cap. When it is necessary to apply gas to an ESM-01 detector, remove the splashguard to allow access to the sensor that protrudes through the detector housing cap. You can then push the appropriate ESM-01 calibration cup onto the sensor. The table below outlines the M2A part numbers and replacement detector part numbers for the ESM-01 detectors.

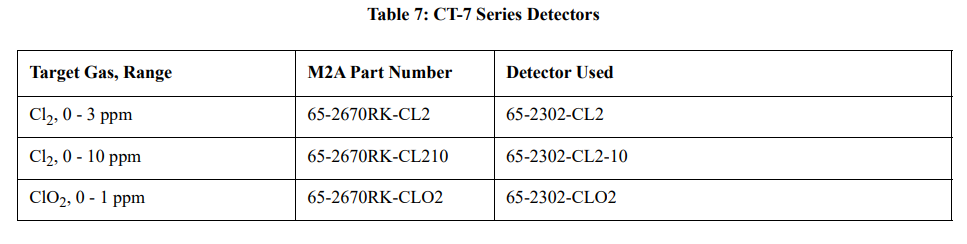

CT-7 Series Detectors

The CT-7 Series detectors for Cl2 and ClO2 have a replaceable plug-in sensor inside the detector housing. An adhesive-backed gasket inside the detector housing cap helps ensure that the sensor remains plugged into the detector housing body. The table below outlines the M2A part numbers and replacement detector part numbers for the CT-7 Series detectors.

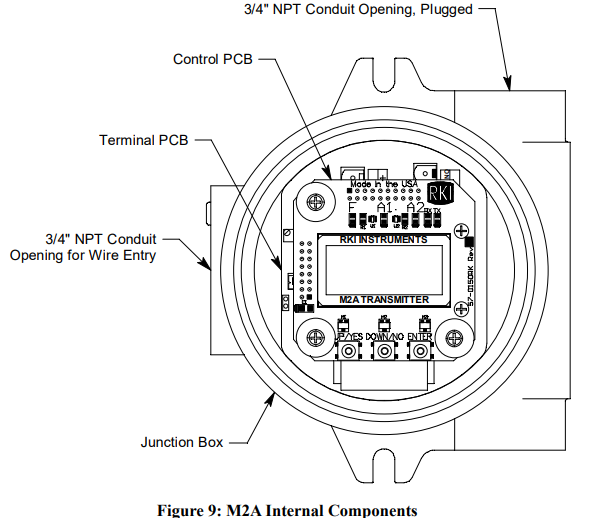

Internal Description

This section describes the internal components of the M2A. The internal components of the M2A include the terminal PCB, which provides for all the wiring connections to the M2A, and the control PCB, which displays the gas reading and has the control buttons.

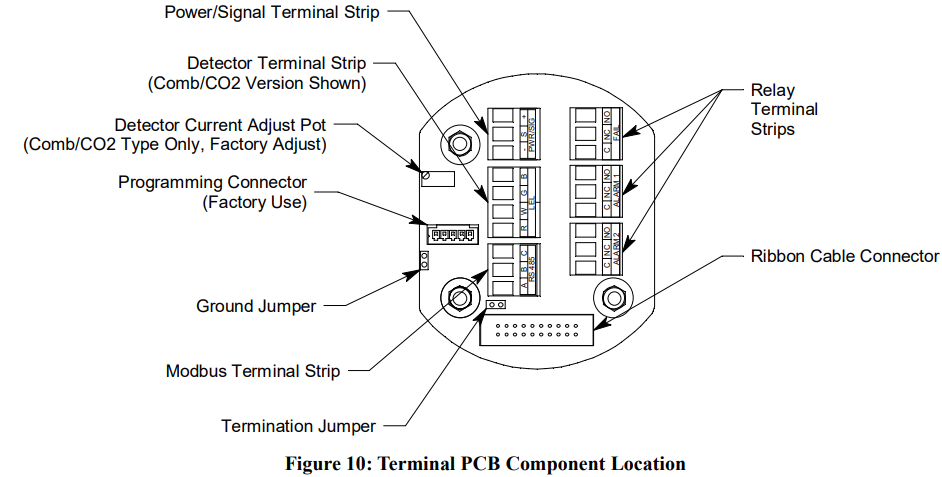

Terminal PCB

The terminal PCB is encapsulated in epoxy for protection against moisture and physical damage. It is mounted into the rear of the junction box with three standoffs and rests on a thin layer of foam. A banana jack is screwed into each of the standoffs and is used for mounting the control PCB.

The terminal PCB converts the electrical output from the detector to a signal which can be displayed by the OLED display, a 4 – 20 mA signal (that is proportional to the detection range), and an RS-485 Modbus output signal. The 4 – 20 mA signal may be used by a recording device, gas monitor controller, or programmable controller. The Modbus output may be used to connect the M2A to a Modbus network.

The terminal PCB also controls three relays: one failsafe and two gas alarms. Two columns of plug-in style terminal strips are used to make all wiring connections to the M2A. The column on the left consists of the power/signal, detector, and Modbus terminal strips. The column on the right consists of the relay terminal strips. A 20-position connector at the bottom of the terminal PCB is used to connect the terminal PCB to the control PCB with a ribbon cable.

A 5-position connector on the left side of the terminal PCB is used by factory or field service personnel to program the M2A. On the combustible and CO2 versions of the M2A, a factory-adjust pot just above the programming connector is used to set the detector current.

Power/Signal Terminal Strip

The power/signal terminal strip is a three-position plug-in style terminal strip located at the top of the left terminal column. It is used to connect 24 VDC power to the M2A and to connect the 4 – 20 mA output signal to a device.

The signal output, the S terminal, does not have to be connected for the M2A to function. The S terminal is used if you want to connect the 4 – 20 mA output signal to another device, such as a gas monitoring controller, chart recorder, or programmable controller (PLC).

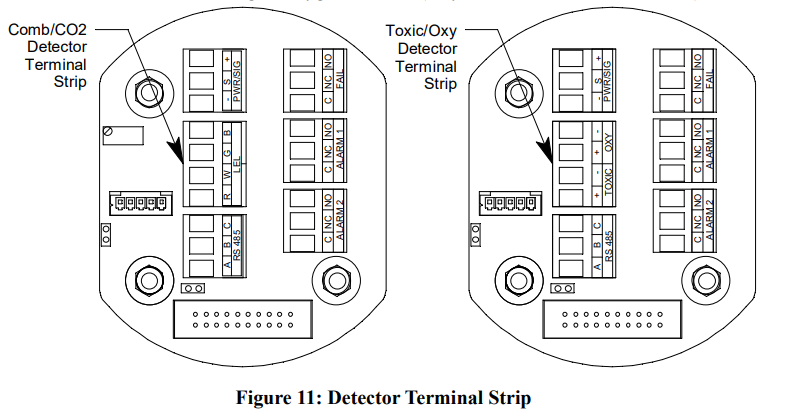

Detector Terminal Strip

The detector terminal strip is a four-position plug-in style terminal strip and is the middle terminal strip in the left terminal column. For a combustible or CO2 M2A, all four terminals are used to connect the detector to the M2A. For a toxic or oxygen M2A, only two of the terminals are used for connecting a detector; two terminals are dedicated to connecting a toxic detector, and two are dedicated to connecting an oxygen detector (only one detector can be installed).

Modbus Terminal Strip

The Modbus terminal strip is a three-position plug-in style terminal strip and is the bottom terminal strip in the left terminal column. It allows connection of the M2A to a Modbus network.

Relay Terminal Strips

The right column of terminal strips consists of, from top to bottom, the fail, alarm 1, and alarm 2 relay terminal strips. They are three-position plug-in style terminal strips. The relay terminal strips are used to connect devices such as lights and horns that are controlled by the relay contacts. The relay contacts are rated at 115 VAC, 5 amps. The relay contacts may also be used to control higher-rated relays.

Termination Jumper

A two-pin header with a termination jumper installed is located below the Modbus terminal strip. Leave this jumper installed unless directed to remove it for a Modbus installation. See “Chapter 8: RS-485 Modbus Output” on page 61 for a description of using the M2A in a Modbus system.

Ground Jumper

A two-pin header with a jumper installed is located along the left side of the terminal PCB. Leave this jumper installed unless directed to remove it for a Modbus installation. See “Chapter 8: RS-485 Modbus Output” on page 61 for a description of using the M2A in a Modbus system.

Control PCB

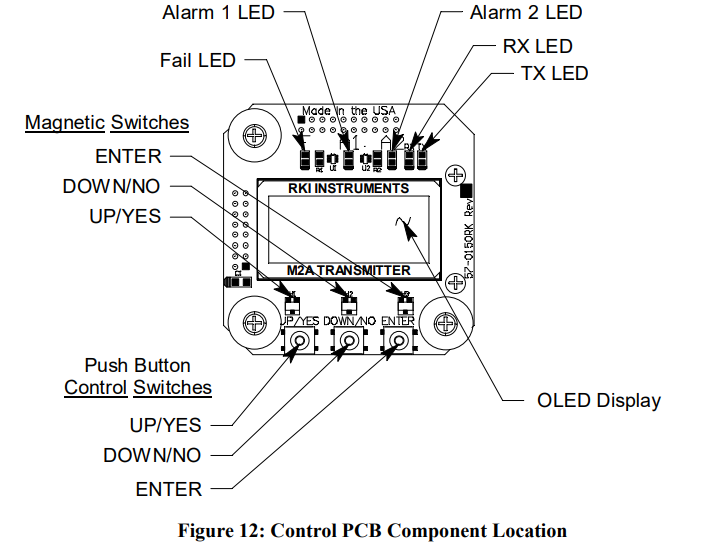

The OLED display and control switches are located on the control PCB. It is installed on top of the terminal PCB by lining up its three spacing standoffs with the banana jacks in the terminal PCB mounting standoffs and pushing it onto the banana jacks. The jacks retain the control PCB.

OLED Display

The OLED display is located at the top of the control PCB. It indicates the current gas reading and displays messages and parameters in the M2A’s programs.

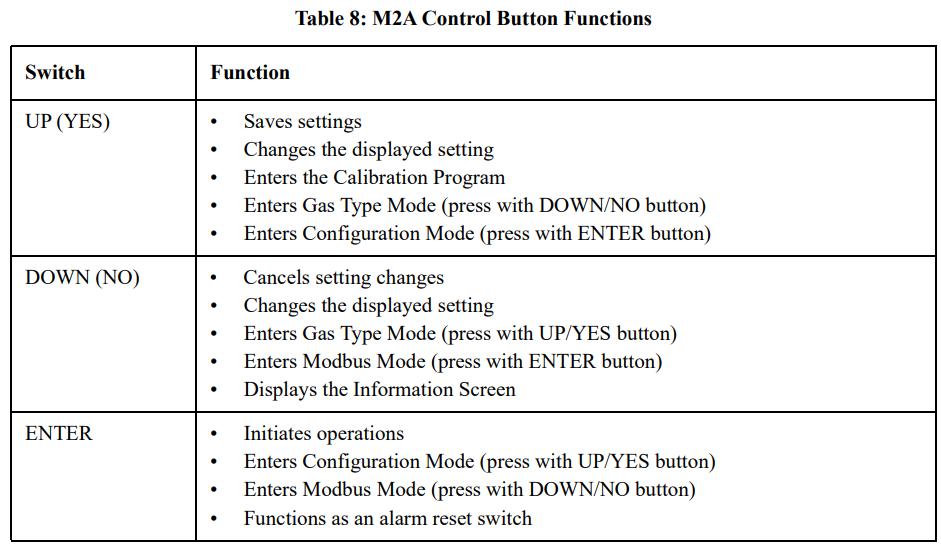

Control Buttons

The M2A includes three push-button switches that allow you to enter the M2A’s operating modes, navigate through the modes, update settings, and save changes to the settings. The push button switches are located along the bottom edge of the control PCB (see Figure 12). The UP/YES button is on the left, the DOWN/NO button is in the middle, and the ENTER button is on the right.

Just above each push button switch is a magnetic switch with the same function as the push button switch below it. The magnetic switches are for use in non-intrusive calibration. They are actuated by bringing the magnetic wand close enough to them to actuate them. Although the magnetic switches have the same functions as the push button switches, it is not practical to use them for operations other than calibration because it is not possible to actuate two magnetic switches at once with only one magnetic wand. Since displaying the Information Screen only requires the use of one switch, the wand may be used to show the Information Screen (see “Information Screen” on page 36).

Status LEDs

The M2A includes five status LEDs that are located above the display (see Figure 12).

- Fail LED: The fail LED turns on when the M2A is experiencing a fail condition. A fail condition can be caused by a detector failure or a low detector signal.

- Alarm 1 LED: The alarm 1 LED is on when the M2A is experiencing an alarm 1 condition.

- Alarm 2 LED: The alarm 2 LED is on when the M2A is experiencing an alarm 2 condition.

- RX & TX LEDs: These LEDs indicate data being received (RX) and transmitted (TX) when the M2A’s Modbus output is operating.

Operation

Overview

This chapter describes the M2A in normal operation. This chapter also describes the M2A in alarm 1, alarm 2, and fail conditions and suggests responses to these conditions.

Normal Operation

Normal operation is defined as follows:

- The start-up procedure is complete.

- The M2A is not indicating an alarm 1, alarm 2, or fail condition.

- The M2A is not in Calibration, Configuration, or Gas Type modes.

During normal operation, the M2A simultaneously displays the current gas reading, unit of measure, and target gas. The example below illustrates a typical combustible gas M2A.

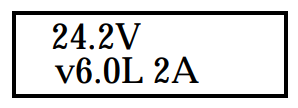

Information Screen

The Information Screen displays the M2A’s operating voltage and firmware, and hardware information. To display the Information Screen, do the following:

- Press and hold the DOWN/NO button for 3 seconds. The Information Screen will appear.

- Continue holding the DOWN/NO button to keep the Information Screen on the display. The top line indicates the operating voltage that is connected to the M2A. The second line indicates the firmware that is running, version 6.0 in this example, and the M2A’s hardware version, version 2A in this example. This information may be useful if you need to contact the factory with questions about the M2A.

- Release the DOWN/NO button when you are done viewing the Information Screen. The display will return to the normal operation screen within a couple of seconds.

4 – 20 mA Signal Output Operation

The output at the S terminal of the power/signal terminal strip is a 4 – 20 mA signal that corresponds to the detection range of the M2A. During normal operation, this signal tracks the gas concentration on the OLED display. There are several circumstances where the signal output will not track the display reading but will behave as follows:

- When the M2A is in its warm-up period, the signal output will be fixed at 1.2 mA.

- When the M2A’s gas type is changed, the M2A will enter Configuration Mode for you to verify the parameter settings. When you exit Configuration Mode, the display will indicate NEEDS CALIBRATION and will continue to indicate this until Calibration Mode is entered and a calibration is performed. In this situation, the signal output will be fixed at 3.5 mA for LEL and toxic versions and 17.4 mA for oxygen versions from the time Gas Type Mode is entered until the M2A is calibrated and returns to normal operation.

- If you enter Calibration Mode, Configuration Mode, Gas Type Mode, or Modbus Mode, the signal output will be fixed at 3.5 mA for combustible gas, CO2, and toxic versions and 17.4 mA for oxygen versions until the M2A returns to normal operation.

- If the M2A’s input power decreases below 9.5 volts so that the M2A is in a low power alarm, the signal output is fixed below 2.4 mA until the low power alarm is cleared.

- If the M2 goes into a fail condition, after a 30-second delay, the signal output is fixed below 2.4 mA until the fail alarm is cleared. During the 30-second delay, the signal output follows the detector output. In the case of a downscale reading, the display and the signal output continue to track the reading down to -99% of full scale (1.15 mA).

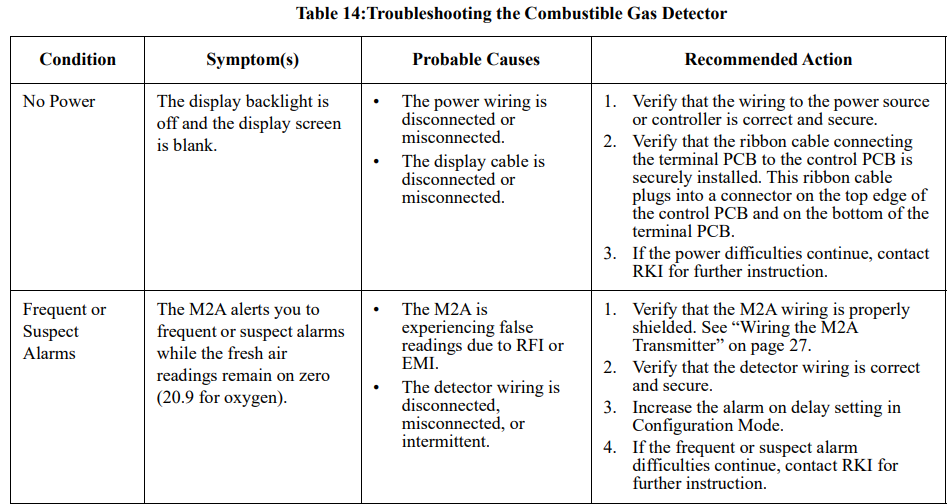

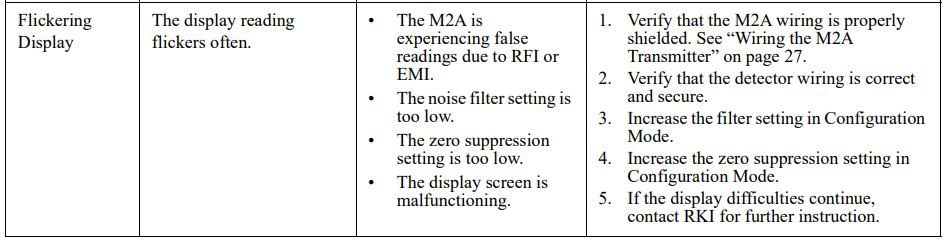

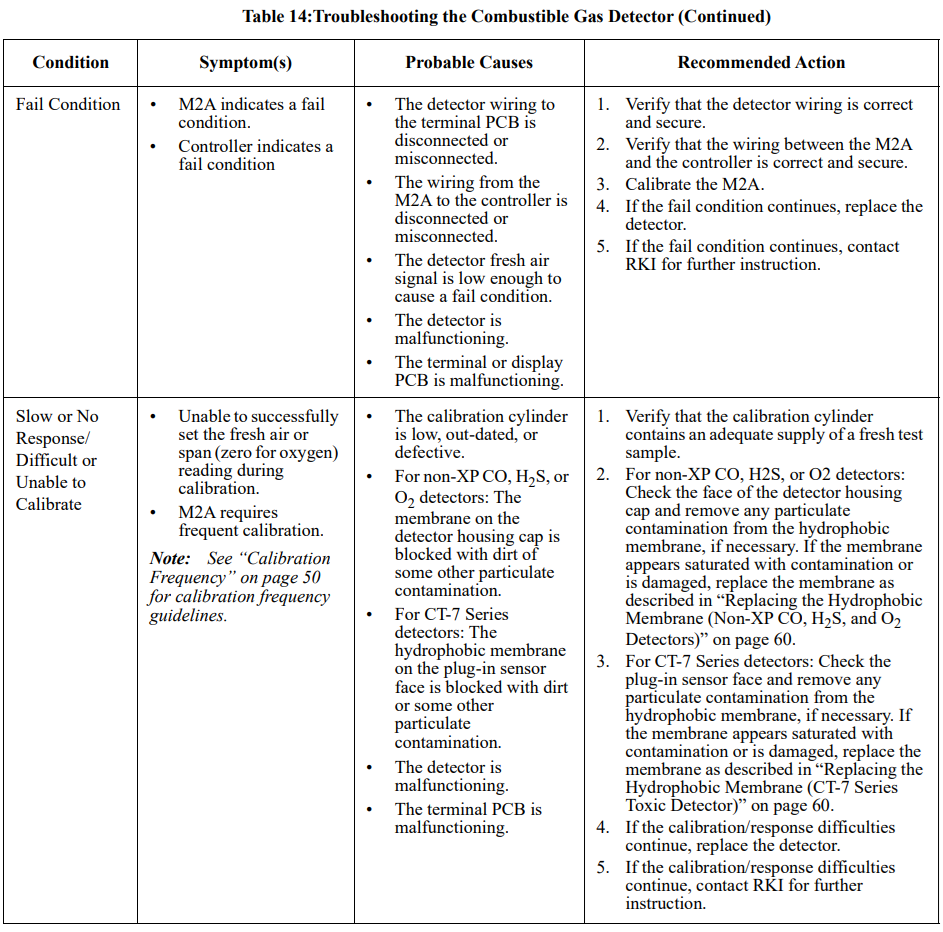

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended actions for problems you may encounter with the M2A.

NOTE: This troubleshooting guide describes M2A problems only. If the M2A is connected to a controller, see the controller operator’s manual for problems you may encounter with the controller.

For More Details, visit www.rkiinstruments.com

For More Manuals By RKI Instruments, Visit ManualsLibraryy.

RKI Instruments M2A-XL Stand Alone Transmitter-FAQs

What does RKI stand for?

RKI is partnered with Riken Keiki Company, Ltd., a world leader in gas detection. RKI Instruments designs and manufactures advanced gas detection solutions globally.

What is the RKI GX-6000 gas monitor?

The GX-6000 is a portable gas detector with a library of 600+ VOCs, customizable lists, strong internal pump, man-down and panic alarms, LED flashlight, and an IP-67 rugged design.

What does an LEL gas detector measure?

An LEL detector measures combustible gases or vapors in the air, shown as a percentage of the Lower Explosive Limit (LEL). This ensures safe monitoring of flammable environments.

What is the RKI 4-gas calibration mixture?

The standard mixture includes 25 ppm H₂S, 50 ppm CO, 50% LEL methane, and 12% O₂ in nitrogen. It is used with RKI calibration stations to keep instruments accurate.

What gases are typically monitored in a 4-gas system?

A standard 4-gas monitor detects oxygen (O₂), combustible gases, carbon monoxide (CO), and hydrogen sulfide (H₂S) to protect workers in hazardous environments.

What is a bump test and why is it needed?

A bump test is a quick functional check where sensors are briefly exposed to target gases. It ensures the transmitter and alarms respond correctly before use.

How do you calibrate the M2A-XL transmitter?

Calibration involves applying a certified test gas using a regulator and tubing. The instrument readings are then adjusted to match the known gas concentrations.

What is transmitter calibration?

Transmitter calibration is the process of aligning the gas sensor readings with a known calibration gas to maintain accuracy and reliability of detection.