Whirlpool WTW5057LW0 Technical Washer

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions, including the following:

- Read all instructions before using the appliance.

- Do not wash articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or explode.

- Do not add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water. These substances give off vapors that could ignite or explode.

- Under certain conditions, hydrogen gas may be produced in a hot-water system that has not been used for 2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot-water system has not been used for such a period, before using a washing machine, turn on all hot-water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. As the gas is flammable, do not smoke or use an open flame during this time.

- Do not allow children to play on or in the appliance. Close supervision of children is necessary when the appliance is used near children.

- Before the appliance is removed from service or discarded, remove the door.

- Do not reach into the appliance if the tub or agitator is moving.

- Do not install or store this appliance where it will be exposed to the weather.

- Do not tamper with controls.

- Do not repair or replace any part of the appliance or attempt any servicing unless specifically recommended in the user maintenance instructions or in published user-repair instructions that you understand and have the skills to carry out.

- Do not use replacement parts that have not been recommended by the manufacturer (e.g., parts made at home using a 3D printer).

- See the Installation Instructions for grounding requirements and installation.

Product Specifications

Whirlpool® Top Load Washer

Dimensions

- Capacity (DOE) US (cu ft): 4.5 or 4.6 or 4.7

- Capacity IEC CAN (cu ft): 5.2 or 5.3 or 5.4

- Depth (IN, inches): 27

- Height with Lid Open: 55¾

- Maximum Height (IN, inches): 42¼

- Minimum Height (IN, inches): 41½

- Net Weight (LB, pounds): 140 or 120

- Washer Door Opening Height (FL) Depth (TL): 18⅞

- Width (IN, inches): 27¾4

- Gross Weight (LB, pounds): 145 or 150

Exterior

- Adjustable Feet: Yes

- Lid/Door Finish: Glass or Metal

- Lid/Door Lock: Yes

- Lid/Door Swing: NA

- Slow Close Lid: Yes for the Glass Lid, No for the Steel Lid

Details

- Automatic Load Size Sensing Technology: Yes

- Dispense System: Bleach Fabric Softener Cap (on some models)

- Out of Balance Sensing: Yes

- Suspension System: 4 Springs 4 Dampers Liquid-filled upper balance ring

- Drum Material: Stainless Steel

- Drum Rear/Base Material: Plastic

- Hoses Included: Drain Hose

- Motor Drive Type: Belt

- Motor Horsepower: 1/3 HP

- Wash Action: Agitator or Impeller, or 2 1 Removable Agitator

- Maximum Spin Speed (RPM): 770

Controls

- Automatic Temperature Controls: Yes

- Control Location: Rear Console

- Control Type: Knob and Button

- Feedback-Status Indicators: Done, Sensing, Soak, Wash

- LED Color: White

Cycles

- Number of Wash Cycles: 12

- Washer Cycle Selections: Activewear, Bulky Items, Clean Washer with affresh®t, Colors, Delicates, Drain & Spin, Heavy Duty, Jeans, Normal, Quick Wash, Towels, Whites

Options

- Number of Washer Options: 5

- Washer Option Selections: Deep Water, Extra Rinse, Fabric Softener, Faucet, 30 min Presoak

Modifiers

- Number of Soil Levels: 1

- Number of Wash/Rinse Temperatures: 5

- Temperature Selections: Hot, Cold, Tap Cold, Cool, Warm

- Number of Rinse Options: 3

- Rinse Temperature: Cold

- Number of Water Levels: 2

- Water Levels: Auto, Deep water

- Number of Spin Speeds: 1

Features

- Pedestal Options: No

- Sound Package: No

- Water Faucet: Yes

Certifications

- CEE Tier: Not Rated

- Energy Rating (kWh/year): 290

- UL: Yes

- IMEF: 1.037

- IWF: 6.5

- Prop 65: Standard

Electrical

- Amps: 15

- HZ: 60

- Power Cord Included: Yes

- Volts: 120

Product Features

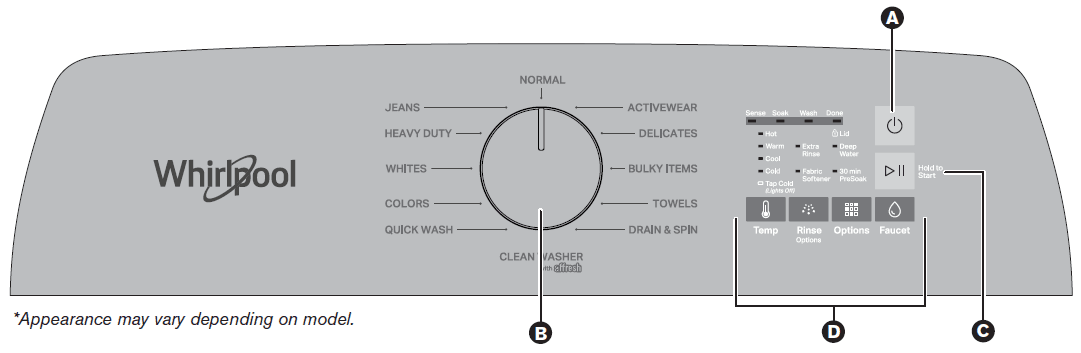

Control Panel

- A. Power

- B. Cycle Knob

- C. Start/Pause

- D. Cycle Modifiers

POWER

Press to turn on/off or to stop/cancel a cycle.

CYCLE KNOB

Turn knob to select desired cycle.

START/PAUSE

Press and hold the Start/Pause button for 1 second until all status lights are illuminated, then release to start cycle. Press during a cycle to pause cycle and unlock lid.

NOTE: If the machine is spinning, it may take longer to unlock the lid.

CYCLE MODIFIERS

(Not all modifiers are available on all cycles.)

Temp

Press to modify the cycle’s available temperatures (Tap-Cold, Cold, Cool, Warm, or Hot).

NOTE: Pressing Temp will toggle through available temperature options. When no lights in the temperature column are illuminated, the selected temperature is Tap Cold.

Rinse Options

Press to modify the cycle’s available rinse options. Press once for Fabric Softener, twice for Extra Rinse,se and three times to activate both.

- FABRIC SOFTENER

Select this option to let the machine know when you have added liquid fabric softener. - EXTRA RINSE

Select this option to add a second rinse.

OPTIONS

Press to add or remove options for each cycle. Press once to add a 30 min PreSoak, twice to activate Deep Water and three times for both.

- DEEP WATER

Use this option to automatically add more water to your wash cycle. You can also use this option to reduce the likelihood of white residue on dark clothing. - 30 MIN PRESOAK

Touch to add a 30-minute presoak period to help loosen tough stains. The washer will fill, pause to soak, and then begin the selected cycle.

Faucet

Press to access an instant water stream. Use this feature to pretreat clothes and other items right in the washer. You can also use this feature to manually add water to the machine as desired.

NOTE: The washer will drain at the beginning of the cycle if a large volume of water is detected to ensure the machine can correctly sense the load size.

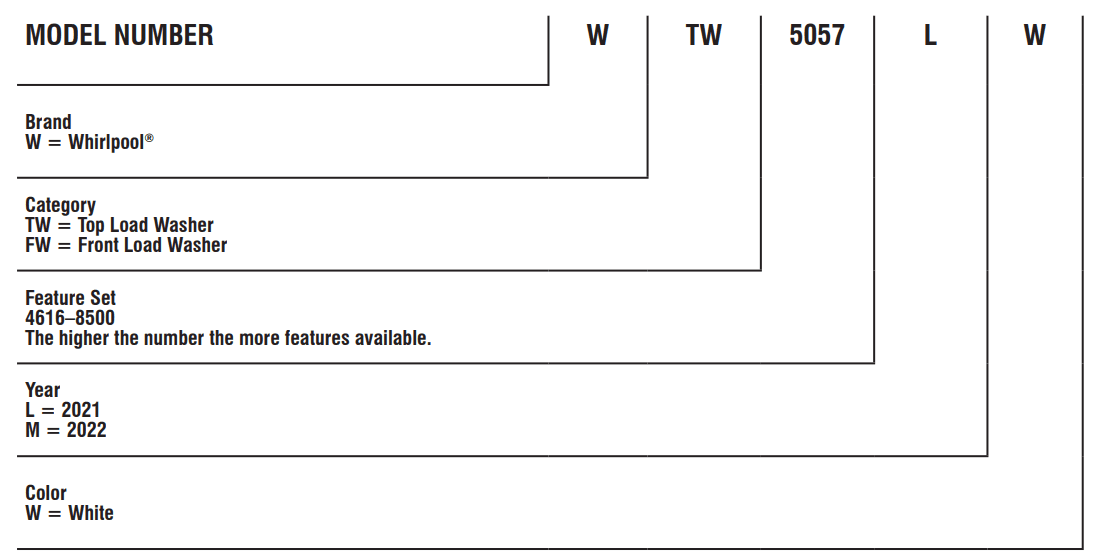

Model Number Nomenclature

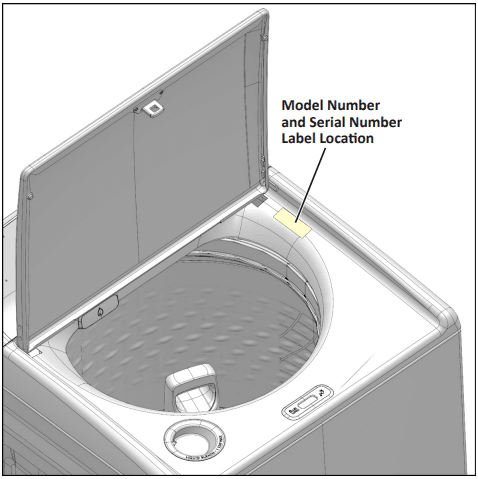

Model Number and Serial Number Label Location

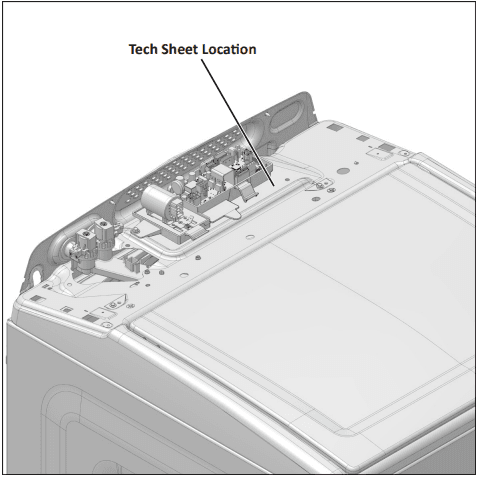

Tech Sheet Location

SERVICE GUIDE

Before servicing, check the following:

- Make sure there is power at the wall outlet.

- Has a household fuse blown or circuit breaker tripped? Was a regular fuse used? Inform the customer that a time-delay fuse is required.

- Are both hot and cold water faucets open and water supply hoses unobstructed?

- Make sure drain hose is not sealed into drain pipe, and that there is an air gap for ventilation. Ensure drain height is between 39″ (991 mm) and 8′ (2.4 m) above the floor.

- All tests/checks should be made with a VOM (volt-ohm-milliammeter) or DVM (digital-voltmeter) having a sensitivity of 20,000 Ω per VDC or greater.

- Resistance checks must be made with the washer unplugged or power disconnected.

IMPORTANT: Avoid using large diameter probes when checking harness connectors as the probes may damage the connectors upon insertion. - Check all harnesses and connections before replacing components. Look for connectors not fully seated, broken or loose wires and terminals, or wires not pressed into connectors far enough to engage metal barbs.

- A potential cause of a control not functioning is corrosion or contamination on connections. Use an ohmmeter to check for continuity across suspected connections.

- To properly check voltage:

- Unplug the appliance or disconnect the power.

- Attach voltage measurement probes to the proper connectors.

- Plug in the appliance or reconnect the power and verify the voltage reading.

- Unplug the appliance or disconnect power after completing voltage measurements.

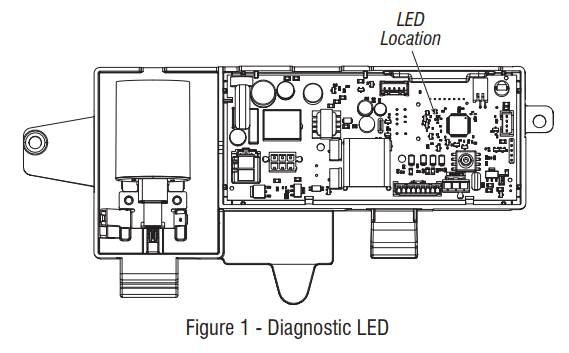

DIAGNOSTIC LED – MAIN CONTROL (ACU)

A troubleshooting tool has been implemented on the main control board—a diagnostic LED.

- LED Flashing – The Control is detecting the correct incoming line voltage, and the processor is functioning.

- LED OFF or ON – Control malfunction. Perform TEST #1: Main Control (ACU), to verify main control functionality.

SERVICE MODE

These tests allow factory or service personnel to test and verify all inputs to the main control board. You may want to do a quick and overall checkup of the washer with these tests before going to specific troubleshooting tests.

Activating Service Diagnostic Mode

- Be sure the washer is in standby mode (plugged in with all LEDs off).

- Follow the steps below within 8 seconds:

- Press and Release Key 1

- Press and Release Key 2

- Press and Release Key 3

- Repeat this 3-button sequence 2 more times

- If this test mode has been entered successfully, all indicators on the HMI will be illuminated for 1 second then will be turned OFF. After this, If there are no saved fault codes, the STATUS indicators (Sense, Soak, Wash and Done) will blink two times and then all the indicators will be turned OFF.

Unsuccessful Activation

If entry into Diagnostic mode is unsuccessful, refer to the following indications and actions:

Indication: None of the LEDs will turn on.

Action: Turn on the appliance by pressing the POWER Button or rotating the knob and select any cycle.

- If LEDs turn on after pressing the POWER Button or turning the knob, then try to enter Service mode again: repeat step 2 mentioned in activating sequence and complete it within 8 seconds. If these re-entry procedures fail to enter into Diagnostic mode, there is likely a faulty button in the HMI. Replace the HMI.

- If no LEDs come on after selecting the cycle, go to TEST #1: Main Control (ACU).

Activation with Saved Fault Codes

If there is a saved fault code, it will be flashing in the display. Review the Fault/Error Codes table on page 20 for the recommended procedure. If there is no saved fault code. All LEDs will turn OFF.

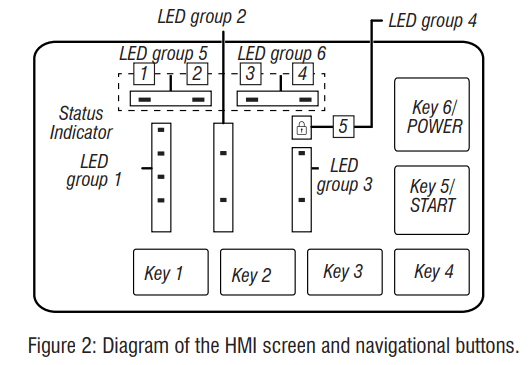

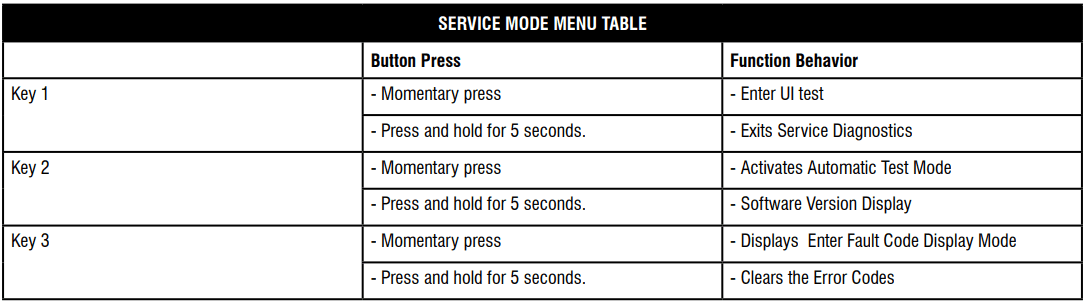

SERVICE MODE MENU TABLE

- See “Activating Service Diagnostic Mode” to activate these buttons.

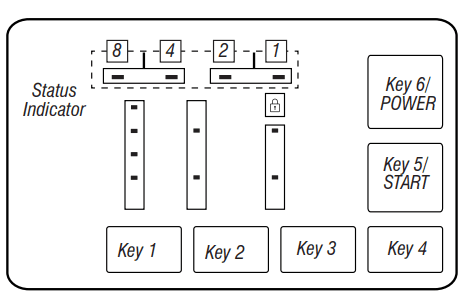

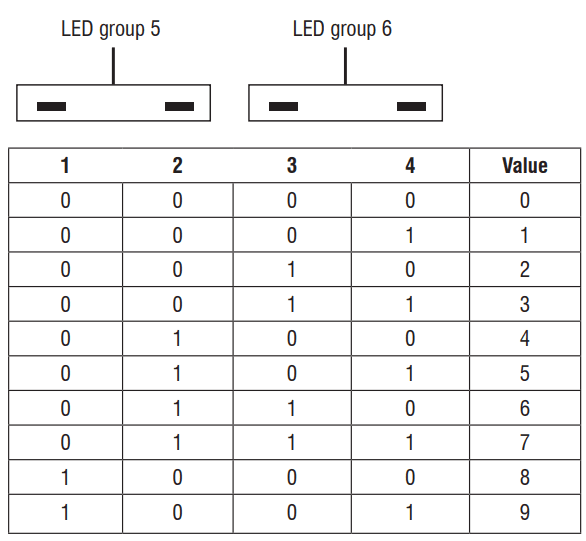

READING BINARY CODES

- LED ON means 1 (has an associated value, see table)

- LED OFF means 0 (has an associated value of zero)

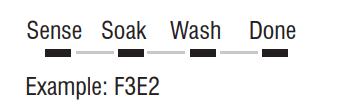

Example: F3E2

- Wash and Done are ON, Lid Lock LED is ON

- All are OFF

- Wash is ON, Lid Lock LED is OFF

- All are OFF

- Back to step 1

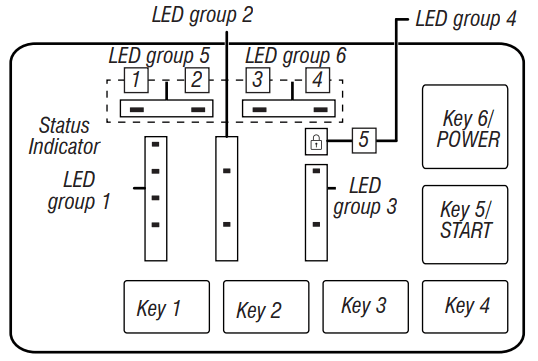

UI TEST

NOTE: The Service Diagnostic mode must be activated before entering the UI Test; see the procedure on page 14.

Entry Procedure

Press and release Key 1 used to activate Service Diagnostic mode. All LEDs will flash once, and then the Sense LED will illuminate. The following test will be available:

DIAGNOSTIC: UI Test

The Encoder Test will be active immediately after successfully entering the UI Test:

- When the encoder test starts, the Sense LED from the progress LEDs will be turned ON.

- Rotate the knob CW/CCW from the current position until a full knob rotation is completed. Notice that the LEDs from Status indicator group will turn ON/OFF while the knob is rotated. After the Encoder Test is completed, all the LEDs will be turned ON, and the Button Activation test will be active.

Button Activation Test

Pressing each button will toggle ON/OFF its corresponding LEDs:

- LED group 1 will toggle ON/OFF with Key 1.

- LED group 2 will toggle ON/OFF with Key 2.

- LED group 3 will toggle ON/OFF with Key 3.

- LED group 4 will toggle ON/OFF with Key 4.

- LED group 5 will toggle ON/OFF with Key 5/START.

- LED group 6 will toggle ON/OFF with Key 6/POWER.

- If LEDs do not toggle ON/OFF after pressing buttons and rotating the cycle selector knob go to TEST: #4 HMI.

Exit Procedure

To exit the UI test, press and hold Key 1 used to activate Service Diagnostic mode for 5 seconds.

AUTOMATIC TEST MODE

NOTE: The Service Diagnostic mode must be activated before entering Automatic test mode; see procedure on Page 14.

NOTE: If, at any point, the user presses the Key 6/POWER button, the washer exits to standby mode.

NOTE: The Lid must be closed to perform the test.

Active Fault Code Display in Automatic Test Mode

If the display begins flashing while in Automatic test mode, it is displaying an active fault code. Active fault codes are codes that are currently detected. Only one active fault code can be displayed at a time.

Entry Procedure

To enter Automatic Test Mode, press and release Key 2 used to activate Service Diagnostic Mode. To start Automatic Test Mode, press Key 5/Start.

Perform All Tests: After pressing the START button, the test sequence from page 17 will start.

Exit Procedure

To exit test mode before test cycles complete, press Key 6/POWER, and the machine will return to Standby mode. When the test is complete, the lid will unlock, all status LEDs will illuminate and then flash twice,ce and the machine will return to the main Service Diagnostic Mode menu. To exit to Standby Mode, press Key 6/POWER.

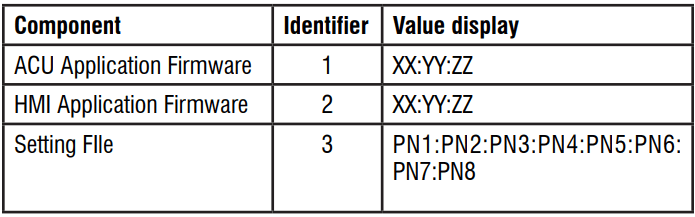

SOFTWARE VERSION DISPLAY

NOTE: The Software Version Display mode will time out after 5 minutes of user inactivity and return to standby mode.

Entry Procedure

To enter Software Version Display, press and hold Key 2 used to activate the Service Diagnostic mode for 5 seconds. Upon entry, the display will automatically cycle through the following information:

- Where XX.YY.ZZ corresponds to the 3 sets of 2-digit numbers that describe a software version and PN1.PN2.PN3.PN4.PN5.PN6.PN7.PN8 is the 8-digit settings file part number.

- The ACU, HMI and Settings file information will be displayed in the LEDs (SENSE, SOAK, WASH, and DONE) in binary format. Consider SENSE LED the most significant bit.

- The identifier value of the component information will be displayed in LED Group1/TEMPERATURE Group in binary format. Consider the HOT LED from the top as the most significant bit. (For Example: Cold LED blinks, then the Identifier is 1. Cold and Cool LED blinks, then the Identifier is 3.

- LED ON = 1, LED OFF = 0.

Exit Procedure

Pressing the POWER button will exit Software Version Display and return theasher to standby mode.

FAULT/ERROR CODES

Refer to service fault/error codes on page 20.

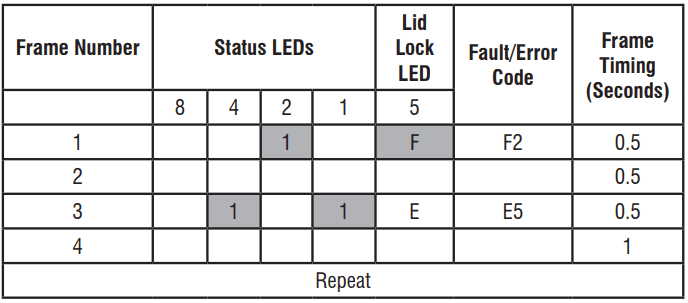

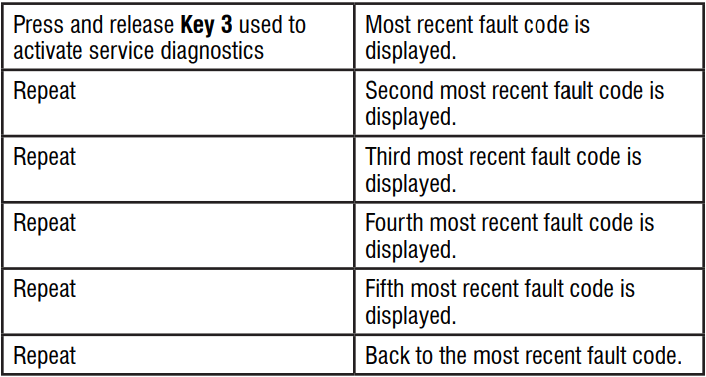

Fault/Error Code Display Method

- Fault codes are composed by a F# and an E#. The F# has two digits and indicates the suspect System/Category. The E# has two digits and indicates the suspect Component system.

- The fault codes are displayed in binary format at the LEDs (SENSE, SOAK, WASH, and DONE). When the LED is ON it represents a binary 1 and when the LED is OFF it represents a binary 0.

Refer to “Reading Binary Codes”. - When the F# digits are displayed, the LID LOCK LED will be turned ON.

- When the E# digits are displayed, the LID LOCK LED will be turned OFF.

Up to five Fault/Error codes may be stored. Additional presses of Key 3 will cause the system to display the next fault code. If there are no fault codes saved, the LEDs will blink twice for each Key 3 press.

Advancing Through Saved Fault/Error Codes

Procedure for advancing through saved fault codes:

Clearing Fault Codes

To clear stored fault codes, enter Service Diagnostic mode. Then press and hold Key 3 used to enter Service Diagnostic mode for 5 seconds. Once the stored fault codes are successfully erased, the LEDs will blink two times. Must be in Fault Code Display mode to erase fault codes.

Exiting Service Diagnostic Mode

Use the method below to exit diagnostic mode.

- Pressing the Key 6/POWER button once.

Factory Calibration Cycle

This calibrates the main control to the washer for optimal load size estimation. Calibration must be performed when any of the following components have been replaced:

- Main Control

- Basket

- Drive Assembly

- Suspension, Motor

- Capacitor and Shifter

Not performing calibration will result in poor wash performance. Do NOT interrupt calibration, disturb the washer, or remove power; otherwise.

Calibration must be repeated.

Basket must be empty to perform test (no water or clothes). Calibration cycle runs for approximately 2 to 4 minutes. Cycle completes when lid unlocks and all LEDs are off.

- Be sure the washer is in standby mode (plugged in with all LEDs off) and the lid is closed.

- Follow the steps below within 8 seconds:

- Press and release Key 1.

- Press and release Key 2.

- Press and release Key 1.

- Press and release Key 2.

- Entry into service mode is confirmed by all LEDs blinking 1 time and the lid locks.

- Rotate the Encoder 1 step. LED status changes in LED groups 5 and 6.

- Press Keys 1 to 6 one by one. Each Key press turns ON/OFF the corresponding group LED.

- Successful completion of the Encoder and Key unlocks the lid.

- Open and close the lid.

- The factory cycle will be initiated by locking the lid.

Exit Procedure

Pressing the Key 6/POWER button anytime will exit Factory Mode.

Troubleshooting

TROUBLESHOOTING GUIDE

NOTE: Always check for Faults and Error Codes first. Some tests will require accessing components. See figures 7 & 8 for Component Locations. For detailed troubleshooting procedures, refer to “Troubleshooting Tests.”

Problem

Won’t Power Up

- No operation

- No keypad response

- No LEDs or display

Possible Cause

- No power to the washer

- Connections between the main control and HMI

- Connection problem between the AC plug and the main control

- User Interface problem

- Main Control problem

Checks & Tests

- Check the power at the outlet, check the circuit breakers, fuses, or junction box connections.

- Check the AC power cord for continuity.

- Check connections and continuity between the main control and HMI. See TEST #4: HMI.

- See TEST #1: Main Control (ACU).

Problem

Won’t Start Cycle

No response when START is pressed

Possible Cause

- Lid lock mechanism not functioning

- Connections between the main control and the HMI User Interface problem

- Main Control problem

Checks & Tests

- Lid lock mechanism not functioning

- The lid is not closed due to interference.

- The lock was not closed due to interference.

- See TEST #7: Lid Lock.

- Check connections and continuity between the main control and HMI.

- See TEST #4: HMI.

- See TEST #1: Main Control (ACU).

Problem

HMI Won’t Accept Selections

Possible Cause

- Connections between the main control and HMI

- User Interface problem

- Main Control problem

Checks & Tests

- Check connections and continuity between the main control and HMI.

- See TEST #4: HMI.

- See TEST #1: Main Control (ACU).

Problem

Won’t Fill

Possible Cause

- No water is supplied to the washer

- Plugged filter/screen

- Drain hose installation

- Valve problem

- Main Control problem

Checks & Tests

- No water is supplied

- Check water connections to the washer.

- Verify that the hot and cold water supply is on.

- Check for a plugged filter or screen in the water valve or hoses.

- Check for proper drain hose installation.

- See TEST #2: Valves.

- See TEST #1: Main Control (ACU).

Problem

Overfills

Possible Cause

- Pressure hose

- Valve problem

- Pressure transducer on the main control

Checks & Tests

- See TEST #5: Water Level.

- See TEST #2: Valves.

- See TEST #1: Main Control (ACU).

Problem

Incorrect Water Temperature

Possible Cause

- Water hose installation

- Valve problem

- Main Control problem

- Water Pressure Too Low

Checks & Tests

- Make sure inlet hoses are connected properly.

- See TEST #2: Valves.

- See TEST #1: Main Control (ACU).

- Chthe eck water pressure of 0.8 bar and ensure the pressure is over ESP.

Problem

Won’t Agitate

Possible Cause

- Water covering the impeller?

- Is the lid lock showing open during the cycle?

- Harness connections

- Shifter problem

- Motor problem

- Main Control problem

Checks & Tests

- See TEST #5: Water Level.

- See TEST #7: Lid Lock.

- Check harness connections between the main control and the drive system.

- See TEST #3a: Drive System – Shifter.

- See TEST #3b: Drive System – Motor.

- See TEST #1: Main Control (ACU).

Problem

Won’t Spin

Possible Cause

- Is the lid lock showing open during the cycle?

- Harness connections

- Shifter problem

- Motor problem

- Main Control problem

Checks & Tests

- See TEST #7: Lid Lock.

- Check harness connections between the main control and the drive system.

- See TEST #3a: Drive System – Shifter.

- See TEST #3b: Drive System – Motor.

- See TEST #1: Main Control (ACU).

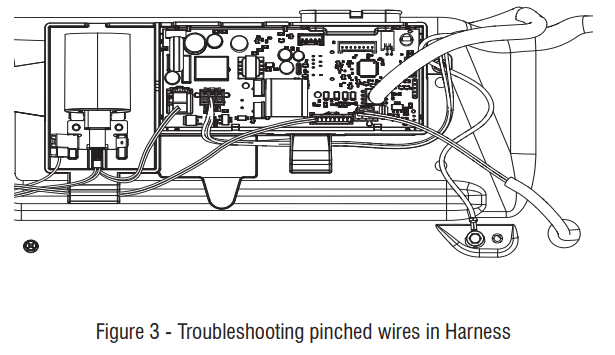

Troubleshooting Pinched Wires in the Harness

IMPORTANT: Verify that the harness is routed under the guides in the main control (ACU) as shown above before re-installing the console.

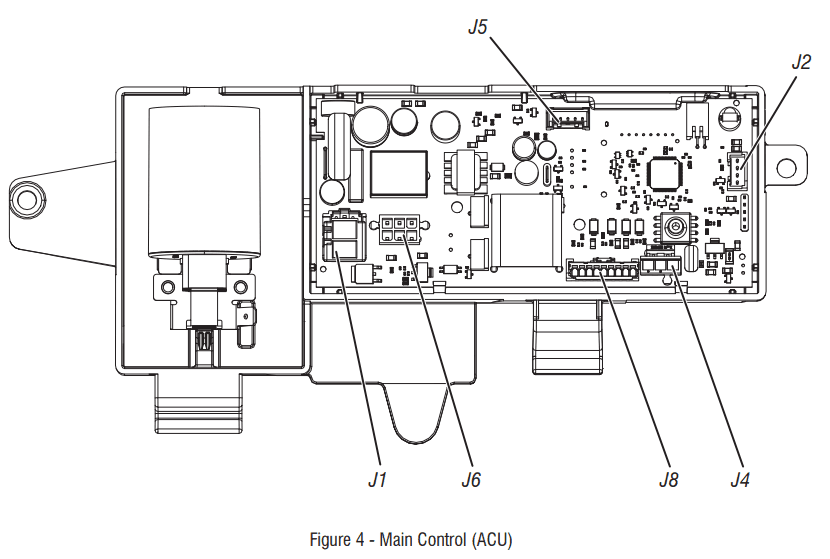

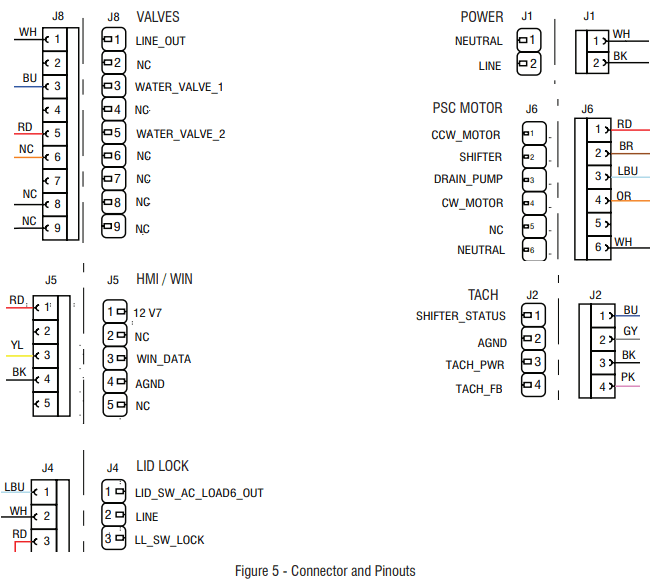

MAIN CONTROL (ACU) BOARD CONNECTORS AND PINOUTS

For more manuals by Whirlpool, visit ManualsLibraryy

Whirlpool WTW5057LW0 Technical Washer- FAQs

How do I run a spin-only cycle?

Turn the cycle selector knob to “Drain & Spin” or “Spin Only.”

Press Start to begin.

How do I use the Clean Washer cycle?

Ensure the drum is empty.

Add an Affresh tablet or liquid chlorine bleach to the drum.

Select the Clean Washer cycle and press Start.

How often should I run the Clean Washer cycle?

Run it once a month to prevent odors and buildup.

Can I use bleach to clean my washer?

Yes, but avoid overusing bleach as it may damage internal components.

Why does my washer show “F5 E3”?

This means the door isn’t locking properly. Check for obstructions and ensure the door is fully closed.

What does “rL” mean on the display?

This indicates items were left in the washer during the Clean Washer cycle. Remove any leftover items and restart.

Why does my washer say “Sd” (Sud Detect)?

Excess suds were detected. The washer will automatically extend rinse time to remove them.

Why is my washer shaking or off-balance?

Overloaded drum – Reduce load size.

Single bulky item – Balance with smaller items.

Uneven flooring – Ensure the washer is level.

What is Permanent Press (Wrinkle Control) mode?

Uses warm water and gentle spin to reduce wrinkles.

Ideal for synthetic fabrics, dress shirts, and casual wear.

What is Quick Wash?

A faster cycle (30–40 mins) for lightly soiled clothes.

When should I use Deep Fill?

Use for large or heavily soiled loads that need extra water.

What spin speed is best for towels?

Use 1200 RPM for faster drying without excessive wear.