Exmark RADIUS Zero Turn Lawn Mower

Slope Operation

Use Extreme caution when mowing and/or turning on slopes as loss of traction and/or tip-over could occur. The operator is responsible for safe operation on slopes.

- See inside the back cover to determine the approximate slope angle of the area to be mowed.

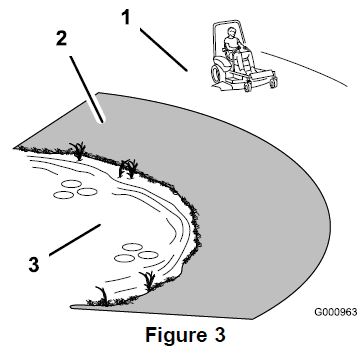

- Use a walk-behind mower and/or a hand trimmer near drop-offs, ditches, steep banks, or water. (Figure 3).

- Safe Zone-Use the mower here on slopes less than 15 degrees

- Danger Zone-Use a walk-behind mower and/or hand trimmer on slopes greater than 15 degrees, near drop-offs and water.

- Water

- Remove or mark obstacles such as rocks, tree limbs, etc. from the mowing area. Tall grass can hide obstacles.

- Watch for ditches, holes, rocks, dips, and rises that change the operating angle, as rough terrain could overturn the machine.

- Avoid sudden starts when mowing uphill because the mower may tip backward.

- Be aware that operating on wet grass, across steep slopes or downhill may cause the mower to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

- Always avoid sudden starting or stopping on a slope. If tires lose traction, disengage the blades and proceed slowly off the slope.

- Follow the manufacturer’s recommendations for wheel weights or counterweights to improve stability.

- Use extreme care with grass catchers or attachments. These can change the stability of the machine and cause a loss of control.

Specifications

Systems Engine

- Engine Specifications: See your Engine Owner’s Manual

- Engine Oil Type: Exmark 4–Cycle Premium Engine Oil

- RPM:

- X- and S-Series: Full Speed: 3750 ±50 RPM (PTO not engaged) Idle: 1500 ±100 RPM

- E-Series: Full Speed: 3600 ±50 RPM (PTO not engaged) Idle: 1500 ±100 RPM

Fuel System

- Capacity: 7.0 gal. (26.5 L)

- Fuel Recommendations:

- For best results, use only clean, fresh, unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

- Oxygenated fuel with up to 10% ethanol or 15% MTBE by volume is acceptable.

- Do Not use ethanol blends of gasoline (such as E15 or E85) with more than 10% ethanol by volume. Performance problems and/or engine damage may result which may not be covered under warranty.

- Do Not use gasoline containing methanol.

- Do Not store fuel either in the fuel tank or fuel containers over the winter unless a fuel stabilizer is used.

- Do Not add oil to gasoline.

- Fuel Filter:

- Kohler: Kohler P/N 24 050 13

- Kawasaki: Kawasaki P/N 49019-0014

- Exmark Engine: Exmark P/N 133-1563

- Fuel Shut-Off Valve:

All Units: 1/4 turn (“ON”, “OFF”).

Electrical System

- Charging System: Flywheel Alternator

- Charging Capacity: 15 amps

- Battery Type: BCI Group U1

- Recommended Minimum Battery CCA: 260 CCA

- Battery Voltage: 12 Volt

- Polarity: Negative Ground

- Fuses:

All units:- 20 amp charging system fuse (not used on Kohler engines)

- 15 amp main fuse

Safety Interlock System

- LCD indicators appear for the PTO, park brake, drive levers, and operator presence in the message display on the RH control panel.

- PTO must be disengaged, the brake engaged, and motion control levers out (neutral lock) to start the engine. (The operator doesn’t need to be in the seat to start the engine.)

- The operator must be in the seat when the PTO is engaged, the brake is disengaged, motion control levers are moved, and the engine stops.

- The engine will stop if either the left, the right, or both levers are moved from the neutral lock position while the brake is engaged.

Operator Controls

- Steering and Motion Control:

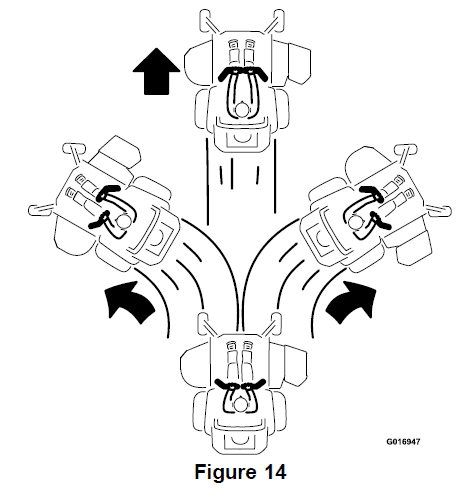

- Separate levers, on each side of the console, control the speed and direction of travel of the respective drive wheels.

- Steering is controlled by varying the position of the levers relative to each other.

- Moving motion control levers outward (in slots) locks the drive system in neutral.

- PTO Engagement Switch: Engages electric clutch (to drive belt) which engages mower blades.

- Parking Brake Lever: Engages parking brake.

- Deck Height Adjustment Lever: Sets cutting height to the desired position.

- Deck Lift Pedal: Foot pedal that lifts the deck.

- Transport Lock: Latching position: Automatically latches at the transport position.

Seat

Seat Type

- X-Series

Deluxe suspension (adjustable spring suspension) seat with high back, molded foam flip-up armrests, and integral safety switch. - S-Series

Standard seat with foam padded seat cushion with armrests, integral safety switch, and adjustable Seat Isolation System suspension for reduced vibration and enhanced ride. - E-Series

Standard seat with foam padded seat cushion with armrests and integral safety switch.

Mounting

- X- and S-Series: Hinged seat frame to tilt up seat. Adjustable fore and aft on seat tracks.

- E-Series: Adjustable fore and aft on seat tracks.

- Armrests: Molded flip-up armrests.

- Seat Safety Switch: Integrated seat switch. Time delay seat switch eliminates rough ground cut-outs.

Hydrostatic Ground Drive System

Two unitized hydrostatic transmissions

- X-Series

Hydro-Gear ZT3400 - S-Series

- Units with side discharge decks: Hydro-Gear ZT3100

- Units with rear discharge deck: Hydro-Gear ZT3400

- E-Series

- Units with 48 or 52-inch decks: Hydro-Gear ZT2800

- Units with 60-inch deck: Hydro-Gear ZT3100

- Hydraulic Oil Type: Exmark Premium Hydro Oil.

- Hydraulic Oil Capaczity: 77 oz (2.3 L) per side

- Hydraulic Filter: P/N 109-3321

- Speeds:

- X-Series

- Forward: 0-10 mph (16.1 km/hr) forward.

- Reverse: 0-7 mph (11.3 km/hr) reverse.

- S-Series

- Forward: 0-9 mph (14.5 km/hr) forward.

- Reverse: 0-6 mph (9.7 km/hr) reverse.

- E-Series

- Forward: 0-8 mph (12.9 km/hr)

- Reverse: 0-5 mph (8.0 km/hr) reverse.

- Drive wheel release valves allow the machine to be moved when the engine is not running.

Tires & Wheels

X-Series

| Drive | ||

| Pneumatic (Air filled) | ||

| Deck Size | 48 & 52 | 60 |

| Quantity | 2 | 2 |

| Tread | K500 | K500 |

| Size | 24 x 9.50-12 | 24 x 10.5-12 |

| Ply Rating | 4 | 4 |

| Pressure | 13 psi (90 kPa) | 13 psi (90 kPa) |

S-Series

| Drive | ||

| Pneumatic (Air filled) | ||

| Deck Size | 48 & 52 | 60 |

| Quantity | 2 | 2 |

| Tread | K500 | K500 |

| Size | 23 x 9.50-12 | 23 x 10.50-12 |

| Ply Rating | 4 | 4 |

| Pressure | 13 psi (90 kPa) | 13 psi (90 kPa) |

Specifications

E-Series

| Drive | ||

| Pneumatic (Air filled) | ||

| Deck Size | 48 & 52 | 60 |

| Quantity | 2 | 2 |

| Tread | K500 | K500 |

| Size | 22 x 9.50-12 | 22 x 10.50-12 |

| Ply Rating | 4 | 4 |

| Pressure | 13 psi (90 kPa) | 13 psi (90 kPa) |

Front Caster — All Models

| Pneumatic (Air filled) | |

| Deck Size | All Models |

| Quantity | 2 |

| Tread | Smooth |

| Size | 13 x 6.50-6 |

| Ply Rating | 4 |

| Pressure | 13 psi (90 kPa) |

Cutting Deck

- Cutting Width

- 48 inch Deck: (121.9 cm)

- 52 inch Deck: (132.1 cm)

- 60 inch Deck: (152.4 cm)

- Discharge

- Side Discharge: Non “R” models

- Rear Discharge: “R” models

- Blade Size

- 48-inch Deck: 16.25 inches (41.3 cm) – (3 ea.)

- 52-inch Deck: 18.00 inches (45.7 cm) – (3 ea.)

- 60-inch Deck: 20.50 inches (52.1 cm) – (3 ea.)

- Blade Spindles

- X-Series: Solid steel spindles with .98 inch (25 mm) I.D. bearings.

- S- and E-Series: Solid steel spindles with .67 inch (17 mm) I.D. bearings.

- Deck Drive: “B” Section belt with self-tensioning idler.

- Electric clutch

- 48 & 52 Inch Decks: 125 ft-lb Mag Stop

- 60 Inch Deck: 125 ft-lb Neo-Mag Stop

- Deck: A full floating deck is attached to the out-front support frame. Anti-scalp rollers provide maximum turf protection. Deck design allows for bagging, mulching, or side discharge.

- 48-inch Deck: 3 anti-scalp rollers

- 52-inch Deck: 5 anti-scalp rollers

- 60-inch Deck: 5 anti-scalp rollers

- 60-inch Deck-Rear Discharge: 4 anti-scalp rollers

- Side Discharge: A full floating deck is attached to the out-front support frame. Anti-scalp rollers provide maximum turf protection. Deck design allows for bagging, mulching, or side discharge.

- Rear Discharge: A full floating deck is attached to the out-front support frame. Anti-scalp rollers and side bumpers provide maximum turf protection. Deck design allows for rear discharge or finish cut (reduced discharge).

Deck Depth

- S- and E-Series

- Side Discharge: 5.0 inches (12.7 cm)

- Rear Discharge: 5.5 inches (14.0 cm)

- X-Series

All Decks: 5.5 inches (14.0 cm) - Cutting Height Adjustment

Foot activated lever is used to adjust the cutting height from 1 1/2 inch (3.8 cm) to 5 inches (12.7 cm) in 1/4 inch (6.4 mm) increments. - Mulching Kit: Optional.

Dimensions

Overall Width

X-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Without Deck | 47.4 inches (120.4 cm) | 48.7 inches (123.7 cm) | 52.1 inches (132.3 cm) |

| Deflector Up | 52.6 inches (133.6 cm) | 57.3 inches (145.5 cm) | 61.7 inches (156.7 cm) |

| Deflector Down | 59.5 inches (151.1 cm) | 64.6 inches (164.1 cm) | 72.7 inches (184.7 cm) |

S-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Without Deck | 47.2 inches (119.9 cm) | 48.5 inches (123.2 cm) | 51.4 inches (130.6 cm) |

| Deflector Up | 52.6 inches (133.6 cm) | 57.3 inches (145.5 cm) | 61.7 inches (156.7 cm) |

| Deflector Down | 59.5 inches (151.1 cm) | 64.3 inches (163.3 cm) | 72.3 inches (183.6 cm) |

E-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Without Deck | 46.7 inches (118.6 cm) | 48.0 inches (121.9 cm) | 51.2 inches (130.0 cm) |

| Deflector Up | 52.6 inches (133.6 cm) | 57.3 inches (145.5 cm) | 61.7 inches (156.7 cm) |

| Deflector Down | 59.5 inches (151.1 cm) | 64.3 inches (163.3 cm) | 72.3 inches (183.6 cm) |

Rear Discharge Units

| 60 inch Deck | |

| Without Deck | 51.4 inches (130.6 cm) |

| With Deck | 66.0 inches (167.6 cm) |

Overall Length

Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck |

| 81.7 inches (207.5 cm) | 81.7 inches (207.5 cm) | 82.2 inches (208.8 cm) |

S-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Drive Wheels | 37.7 inches (95.8 cm) | 39.0 inches (99.1 cm) | 40.7 inches (103.4 cm) |

| Caster Wheels | 33.1 inches (84.1 cm) | 33.1 inches (84.1 cm) | 38.2 inches (97.0 cm) |

E-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Drive Wheels | 37.7 inches (95.8 cm) | 39.0 inches (99.1 cm) | 40.7 inches (103.4 cm) |

| Caster Wheels | 33.1 inches (84.1 cm) | 33.1 inches (84.1 cm) | 38.2 inches (97.0 cm) |

E-Series—Side Discharge Units

| 60 inch Deck | |

| Drive Wheels | 40.7 inches (103.4 cm) |

| Caster Wheels | 31.0 inches (78.7 cm) |

Rear Discharge Units

| 60 inch Deck | |

| Without Deck | 51.4 inches (130.6 cm) |

| With Deck | 66.0 inches (167.6 cm) |

Tread Width: (Center to Center of Tires, Widthwise)

X-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Drive Wheels | 37.7 inches (95.8 cm) | 39.0 inches (99.1 cm) | 40.7 inches (103.4 cm) |

| Caster Wheels | 33.1 inches (84.1 cm) | 33.1 inches (84.1 cm) | 38.2 inches (97.0 cm) |

S-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Drive Wheels | 37.7 inches (95.8 cm) | 39.0 inches (99.1 cm) | 40.7 inches (103.4 cm) |

| Caster Wheels | 33.1 inches (84.1 cm) | 33.1 inches (84.1 cm) | 38.2 inches (97.0 cm) |

E-Series—Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck | |

| Drive Wheels | 37.7 inches (95.8 cm) | 39.0 inches (99.1 cm) | 40.7 inches (103.4 cm) |

| Caster Wheels | 33.1 inches (84.1 cm) | 33.1 inches (84.1 cm) | 38.2 inches (97.0 cm) |

Rear Discharge Units

| 60 inch Deck | |

| Drive Wheels | 40.7 inches (103.4 cm) |

| Caster Wheels | 31.0 inches (78.7 cm) |

Wheel Base: (Center of Caster Tire to Center of Drive Tire)

Side Discharge Units

| 48 inch Deck | 52 inch Deck | 60 inch Deck |

| 49.7 inches (126.2 cm) | 49.7 inches (126.2 cm) | 50.2 inches (127.5 cm) |

Curb Weight

| Units with 48 Inch Side Discharge Decks | 849-937 lb (385-425 kg) |

| Units with 52 Inch Side Discharge Decks | 862-957 lb (391–434 kg) |

| Units with 60 Inch Side Discharge Decks | 901-1006 lb (409-456 kg) |

| Units with 60 Inch Rear Discharge Decks | 1012 lb (459 kg) |

Torque Requirements

| Bolt Location | Torque |

| X-Series: Blade Drive Sheave Mounting Nut | 130-160 ft-lb (176-217 N-m) |

| S- and E-Series: Blade Drive Sheave Mounting Nut | 75-85 ft-lb (102-115 N-m) |

| Blade Mounting Bolt (lubricate with anti-seize) | 50-60 ft-lb (68-81 N-m) |

| Anti-Scalp Roller Nyloc Nut — Side Discharge Units Only (See Figure 18 ) | 50-55 ft-lb (68-75 N-m) |

| Anti-Scalp Roller Nyloc Nut — Rear Discharge Units Only (See Figure 19 ) | 30-35 ft-lb (41-47 N-m) |

| Engine Mounting Bolts | 27-33 ft-lb (37-45 N-m) |

| Wheel Lug Nuts | 90-100 ft-lb (122-136 N-m) |

| Rollover Protection System (Roll Bar) 1/2 inch Mounting Bolts | 90-100 ft-lb (122-136 N-m) |

| Clutch Retaining Bolt (secured with thread locker) | 49-61 ft-lb (66-83 N-m) |

| Rear Discharge Side Bumpers | 10-12 ft-lb (14-16 N-m) |

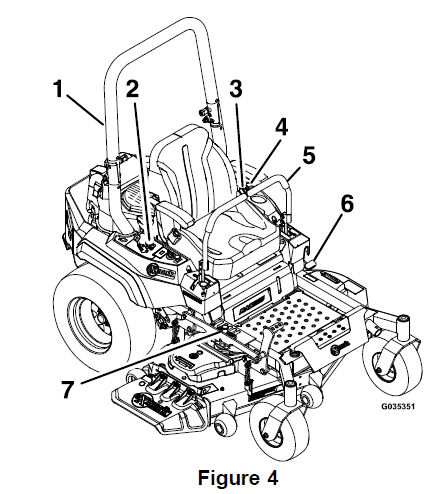

Product Overview

- Rollover Protection System (ROPS)

- Engine Controls (right console)

- Seat belt 7. Height of cut adjustment

- Fuel cap

- Motion control levers

- Parking brake

- Height of cut adjustment

Controls

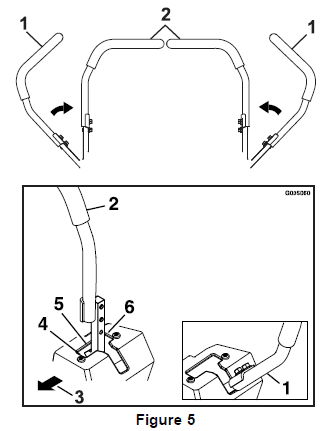

Motion Control Levers

The motion control levers are located on each side of the console and control the forward and reverse motion of the machine. Moving the levers forward or backward turns the wheel on the same side forward or reverse respectively. Wheel speed is proportional to the amount the lever is moved. Moving the levers outward from the center position into the T-slot locks them in the neutral position (Figure 5).

- Neutral lock position (handles out)

- Neutral operate position (handles in)

- Front of unit

- Forward

- Neutral (operate)

- Reverse

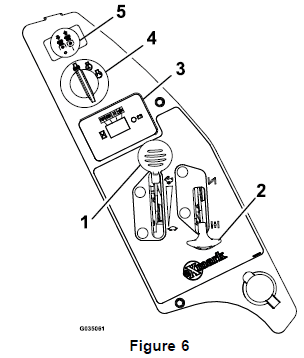

Choke Control

Located on the right console (black lever) (see Figure 6). The choke is used to aid in starting a cold engine. Moving the choke lever forward will put the choke in the “ON” position and moving the choke lever to the rear, to the detent, will put the choke in the “OFF” position. Do Not run a warm engine with a choke in the “ON” position.

- Throttle lever

- Choke lever

- Hour meter

- Ignition switch

- Blade control switch (power take-off)

Throttle Control

Located on the right console (red lever) (see Figure 6). The throttle is used to control engine speed. Moving the throttle lever forward will increase engine speed and moving the throttle lever to the rear will decrease engine speed. Moving the throttle forward into the detent is full throttle.

Brake Lever

Located on the left side of the unit, just to the front of the LH motion control lever. The brake lever engages a parking brake on the drive wheels. Pull the lever up and rearward to engage the brake. Push the lever forward and down to disengage the brake. The unit must be tied down and the brake engaged when transporting.

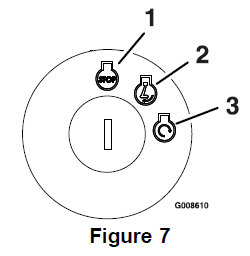

Ignition Switch

Located on the right console (see Figure 6). The ignition switch is used to start and stop the engine. The switch has three positions “OFF”, “ON” and “START”. Insert key into the switch and rotate clockwise to the “ON” position. Rotate clockwise to the next position to engage the starter (the key must be held against spring pressure in this position). Allow the key to return to the “ON” position immediately after the engine starts.

- Off

- On

- Start

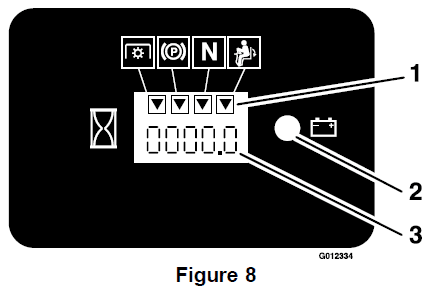

Hour Meter

Located on the control panel (see Figure 6 and Figure 8). The hour meter records the number of hours that the engine has run.

- LCD indicators

- Low voltage indicator light

- Hour/Voltage display

Deck Lift Pedal

Located at the right front corner of the floor pan. Push the pedal forward with your foot to raise the cutting deck. Allow the pedal to move rearward to lower the cutting deck to the cut height that has been set.

- Transport lock knob

- Height adjustment pin

- Height of cut decal

- Deck foot pedal

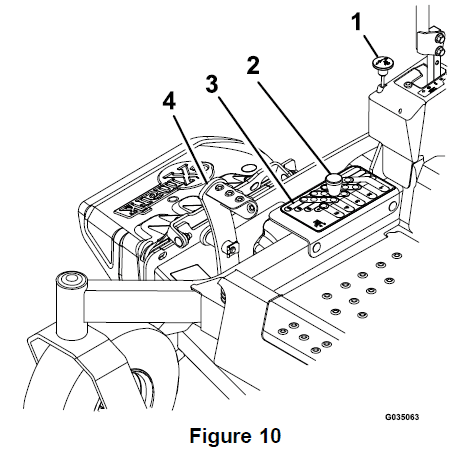

To release the drive system (see item 1 in Figure 9), loosen the knob by turning counterclockwise. Then pull the release lever on the underside of the machine towards the back of the machine and retighten the knob to hold the release lever back in the released state. Repeat this on each side of the machine.

Release the parking brake. The machine is now able to be pushed by hand. To reset the drive system (see item 2 in Figure 9), loosen the knob by turning counterclockwise. Then push the release lever on the underside of the machine towards the front of the machine and retighten the knob to hold the release lever in the operating state. Repeat this on each side of the machine.

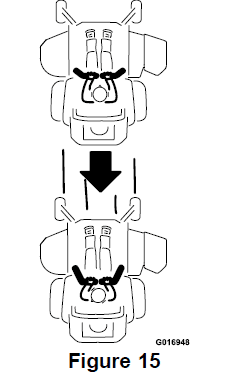

Driving Forward

- Release the parking brake.

- Move the motion control levers inward to the center to the neutral position.

- To move forward in a straight line, move both levers forward with equal pressure.

Driving in Reverse

- Move the motion control levers inward to the neutral operating position.

- To move rearward in a straight line, move both levers rearward with equal pressure.

Adjusting the Cutting Height

The cutting height of the mower deck is adjusted from 1 1/2 to 5 inches (3.8 cm to 12.7 cm) in 1/4 inch (6.4 mm) increments.

- Stop the machine and move the motion control levers outward to the neutral locked position.

- Disengage the PTO.

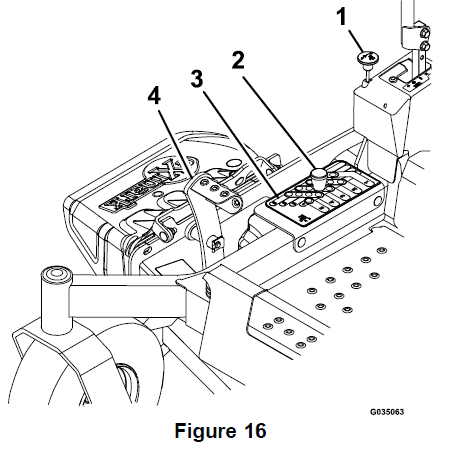

- Raise and lock the deck to the transport position (Figure 16). The deck is raised by pushing the foot-operated deck lift pedal forward. The pedal is located at the front right corner of the floor pan.

- Transport lock knob

- Height adjustment pin

- Insert the height adjustment pin into the hole corresponding to the desired cutting height. See the decal on the top of the deck lift plate for cut heights.

- Push the foot lever forward, pull up on the transport lock knob, and let the deck lower down to the predetermined cut height by slowly decreasing foot pressure allowing the foot lever to travel rearward.

Adjusting the Anti-Scalp Rollers

It is recommended to change the anti-scalp roller position when the height has changed.

- Stop the machine and move the motion control levers outward to the neutral locked position.

- Disengage the PTO.

- Engage the parking brake.

- Stop the engine, remove the key, and wait for all moving parts to stop.

- After adjusting the height of the cut, adjust the anti-scalp rollers by removing the mounting hardware.

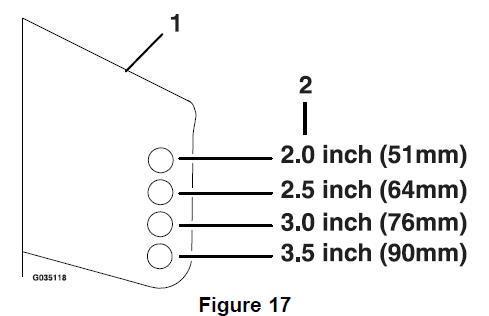

- Place the rollers in one of the positions shown (Figure 17). Rollers will maintain 3/4 inch (19 mm) clearance to the ground to minimize gouging and roller wear or damage.

For cutting heights above 3.5 inches (90 mm) use the bottom hole. The rollers will still be effective against scalping.

- Anti-scalp roller mounting bracket

- Cutting height

Side Discharge Units

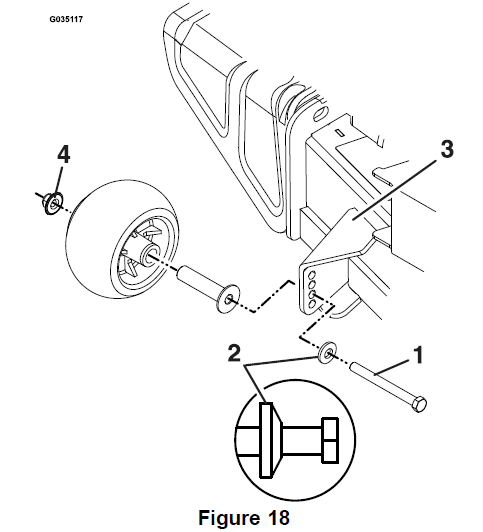

- A. Be sure the roller bolts are installed with the spring disc washer between the head of the bolt and the mounting bracket (see Figure 18).

- B. Torque the 3/8 nyloc nut to 50–55 ft-lb (68-75 N-m)

- 3/8-16 X 3 3/4 inch Grade 8 bolt

- Spring disc washer (cone towards bolt head)

- The front right anti-scalp bracket shown

- 3/8 inch nylon torque to 50-55 ft-lb (68-75 N-m)

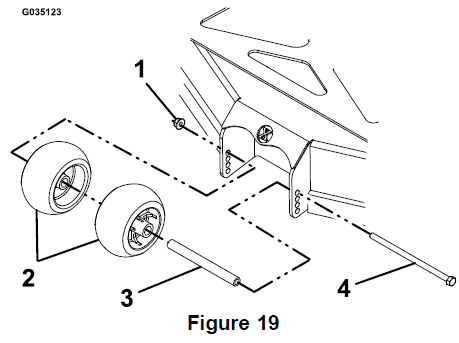

Rear Discharge Units

Torque the 3/8 nyloc nut to 30-35 ft-lb (41-47 N-m) (see Figure 19 ).

- 3/8 inch nylon torque to 50-55 ft-lb (68-75 N-m)

- Anti-scalp rollers

- Wheel spacer

- 3/8-16 X 7 3/8 inch bolt

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

| After the first 5 hours | • Change the engine oil (Exmark 708cc Engine). • Change the engine oil (Kohler Engine). • Change the engine oil (Kawasaki Engine). |

| After the first 75 hours | • Change the hydraulic filter and fluid. |

|

Before each use or daily | • Check the air cleaner for dirty, loose, or damaged parts. • Check the engine oil (Exmark 708cc Engine). • Check the engine oil (Kohler Engine). • Check the engine oil (Kawasaki Engine). • Check the mower blades. • Check the safety interlock system. • Check the rollover protection systems (roll bar) knobs. • Check the seat belt. • Check for loose hardware. • Check the hydraulic oil level in the expansion tank. • Clean the engine and exhaust system area. • Clean the grass and debris build-up from the machine and cutting deck. • Clean the grass build-up from under the cutting deck. |

|

Every 25 hours | • Clean the air cleaner foam element (more often in dusty, dirty conditions)(Exmark 708cc engine). • Service or replace the air cleaner pre-cleaner (more often under extremely dusty, dirty conditions)(Kohler engine). • Grease the front caster axles (S- and E-Series Only). |

|

Every 50 hours | • Service the air cleaner paper element (more often under extremely dusty, dirty conditions)(Kohler engine). • Check the tire pressures. • Check the condition of the belts. • Grease the deck and pump idler pivot. • Check spark arrester (if equipped). |

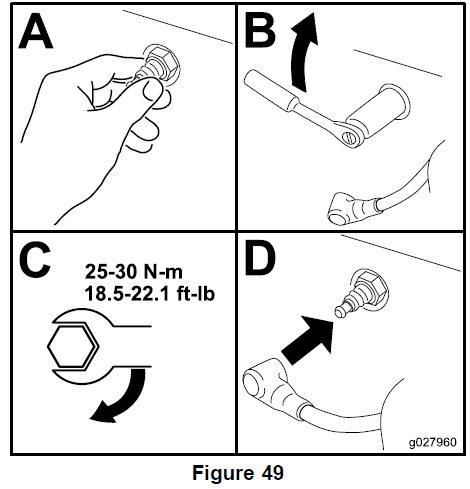

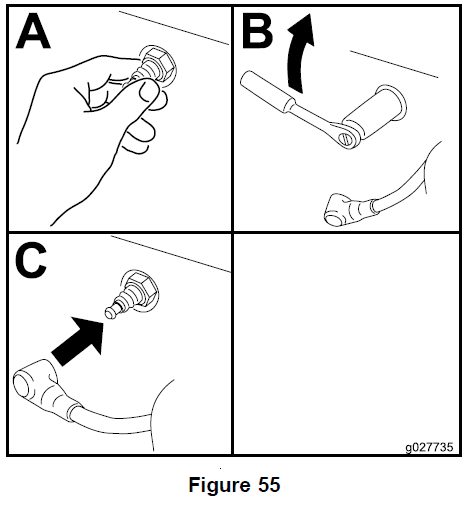

Installing the Spark Plug–Exmark 708cc Engine

- Install the spark plug. Make sure that the air gap is set correctly.

- Tighten the spark plug to 18.5–22.1 ft-lb (25–30 N-m).

- Push the wire onto the spark plug.

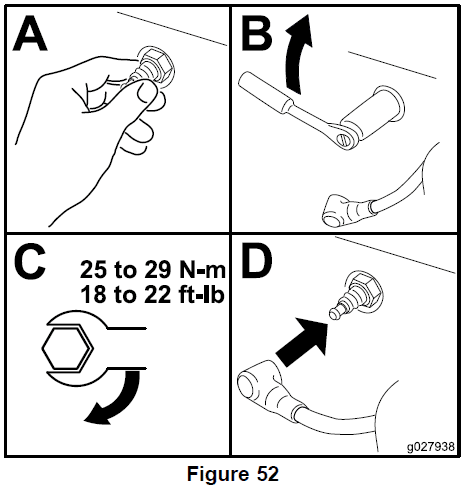

Installing the Spark Plug–Kohler Engine

- Install the spark plug. Make sure that the air gap is set correctly.

- Tighten the spark plug to 18 to 22 ft-lb (25 to 29 N-m).

- Push the wire onto the spark plug.

Installing the Spark Plug–Kawasaki Engine

- Install the spark plug. Make sure that the air gap is set correctly.

- Tighten the spark plug to 16 ft-lb (22 N-m).

Troubleshooting

Important: It is essential that all operator safety mechanisms be connected and in proper operating condition before mower use.

When a problem occurs, do not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. Do not attempt to service or replace major items or any items that call for special timing of adjustment procedures (such as valves, governor, etc.). Have this work done by your Engine Service Dealer.

| Problem | Possible Cause | Corrective Action |

| The starter does not crank | 1. PTO is engaged. 2. The parking brake is not engaged. 3. Drive levers are not in a neutral lock position. 4. The battery does not have a full charge.

5. Electrical connections are corroded, loose, or faulty.

6. The fuse is blown. 7. Relay or switch is defective. 8. Faulty module. | 1. Disengage the PTO. 2. Set the parking brake. 3. Ensure the drive levers are in the neutral lock position. 4. Charge the battery. See the Check Battery Charge and Recommended Jump Starting Procedure sections in Maintenance. 5. Check the electrical connections for good contact. Clean connector terminals thoroughly with an electrical contact cleaner, apply dielectric grease, and reconnect. 6. Replace the blown fuse. 7. Contact an Authorized Service Dealer. 8. Replace module. |

| The engine will not start, starts hard, or fails to keep running | 1. The fuel tank is empty. 2. The fuel shutoff valve is closed. 3. The oil level in the crankcase is low. 4. The throttle and choke are not in the correct position.

5. Dirt in fuel filter. 6. Dirt, water, or stale fuel is in the fuel system. 7. The air cleaner is dirty. 8. The seat switch is not functioning properly.

9. Electrical connections are corroded, loose, or faulty.

10. Relay or switch is defective. 11. Faulty spark plug. 12. Spark plug wire is not connected. 13. Faulty module. | 1. Fill the fuel tank. 2. Open the fuel shutoff valve. 3. Add oil to the crankcase. 4. Be sure the throttle control is midway between the “SLOW” and “FAST” positions, and the choke is in the “ON” position for a cold engine or the “OFF” position for a warm engine. 5. Replace the fuel filter. 6. Contact an Authorized Service Dealer.

7. Clean or replace the air cleaner element. 8. Check the seat switch indicator. Replace the seat if needed. 9. Check the electrical connections for good contact. Clean connector terminals thoroughly with an electrical contact cleaner, apply dielectric grease, and reconnect. 10. Contact an Authorized Service Dealer. 11. Clean, adjust, or replace the spark plug. 12. Check the spark plug wire connection. 13. Replace module. |

Troubleshooting

| Problem | Possible Cause | Corrective Action |

| Engine loses power | 1. Engine load is excessive 2. The air cleaner is dirty. 3. The oil level in the crankcase is low. 4. Cooling fins and air passages for the engine are plugged. 5. Dirt in fuel filter. 6. Dirt, water, or stale fuel is in the fuel system. | 1. Reduce the ground speed. 2. Clean or replace the air cleaner element. 3. Add oil to the crankcase. 4. Remove the obstructions from the cooling fins and air passages. 5. Replace the fuel filter. 6. Contact an Authorized Service Dealer. |

| The mower pulls left or right (with levers fully forward) | 1. Tire pressure in drive tires is not correct. | 1. Adjust tire pressure in the drive tires. |

| The machine does not drive | 1. The drive release handle is not in the “operating” position.

2. The drive or pump belt is worn, loose, or broken. 3. The drive or pump belt is off a pulley. 4. Broken or missing idler spring. 5. The hydraulic fluid level is low or too hot. | 1. Position handle in “operating” position; see Drive Wheel Release Valves section in Operation. 2. Change the belt.

3. Change the belt. 4. Replace the spring. 5. Add hydraulic fluid to the reservoir or let it cool down. |

| Uneven cutting height. | 1. Blade(s) not sharp. 2. Cutting blade(s) is/are bent. 3. The mower deck is not level.

4. The underside of the mower is dirty. 5. Tire pressure in drive tires is not correct. 6. Blade spindle bent. 7. Tips of adjacent blades are at an uneven cutting height. Blade tips should be even within 3/16 inch which is approximately one blade thickness. |

2. Install new cutting blade(s). 3. Level the mower deck from side to side and front to rear. 4. Clean the underside of the mower. 5. Adjust tire pressure in the drive tires. 6. Contact an Authorized Service Dealer. 7. Replace blades, and spindles and (or) check for damage to the mower deck. |

| Abnormal vibration | 1. Cutting blade(s) is/are bent or unbalanced. 2. The blade mounting bolt is loose. 3. Engine mounting bolts are loose. 4. Loose engine pulley, idler pulley, or blade pulley. 5. The engine pulley is damaged. 6. The blade spindle is bent. | 1. Install new cutting blade(s). 2. Tighten the blade mounting bolt. 3. Tighten the engine mounting bolts. 4. Tighten the appropriate pulley.

5. Contact an Authorized Service Dealer. 6. Contact an Authorized Service Dealer. |

| Blades do not rotate. | 1. The drive belt is worn, loose, or broken. 2. The deck belt is worn, loose, or broken. 3. The deck belt is off the pulley.

4. Broken or missing idler spring. 5. The drive belt is not routed correctly. | 1. Check the belt tension. 2. Install a new deck belt. 3. Install belt on clutch and deck pulleys, idlers, and tensioning idlers per routing decal on deck. 4. Replace the spring. 5. Refer to the belt routing decal on the deck. |

For more manuals by Exmark visit, ManualsLibraryy

Exmark RADIUS Zero Turn Lawn Mower-FAQs

How do I start a battery-operated lawn mower?

Press and hold the start button, then pull the start handle. Your mower should start immediately.

How often should I change the oil in my Exmark zero-turn mower?

1. Change the oil every 50 hours of operation or once per season.

2. Replace the oil filter every 100 hours or seasonally.

3. Change the spark plug every 100 hours or seasonally.

What type of engine does Exmark use?

Exmark mowers are powered by a 708cc V-twin engine, designed specifically for zero-turn mowers to ensure durability and top performance.

What kind of oil should I use in my Exmark zero-turn mower?

Exmark recommends using SAE 30 or SAE 10W-30 synthetic blend engine oil for optimal performance.

How fast does an Exmark zero-turn mower go?

The Exmark Radius zero-turn mower can reach speeds of:

1. Up to 7 mph with the Hydro-Gear ZT2200 hydro drive system.

2. Up to 9 mph in the S-Series with a Kawasaki engine.

What is the minimum turning radius?

The minimum turning radius is the smallest space a vehicle can turn in without hitting obstacles, crucial for tight spaces like parking lots or narrow paths.

What is the maximum slope a zero-turn mower can handle?

Exmark zero-turn mowers should not be used on slopes steeper than 15 degrees for safety.

How do I start a zero-turn mower?

1. Insert the key into the ignition and turn it to the START position.

2. Slowly open the choke by pushing the knob down as the engine starts.

3. Let the engine warm up for at least a minute before engaging the PTO switch or driving the mower.